High temperature heating furnace device for testing of high temperature mechanical properties of material

A high-temperature mechanics and high-temperature heating technology, applied in measuring devices, using stable bending force to test the strength of materials, analyzing materials, etc., can solve the problems that metal fixtures cannot be used for high temperature and long-term experiments. Fast, uniform furnace temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

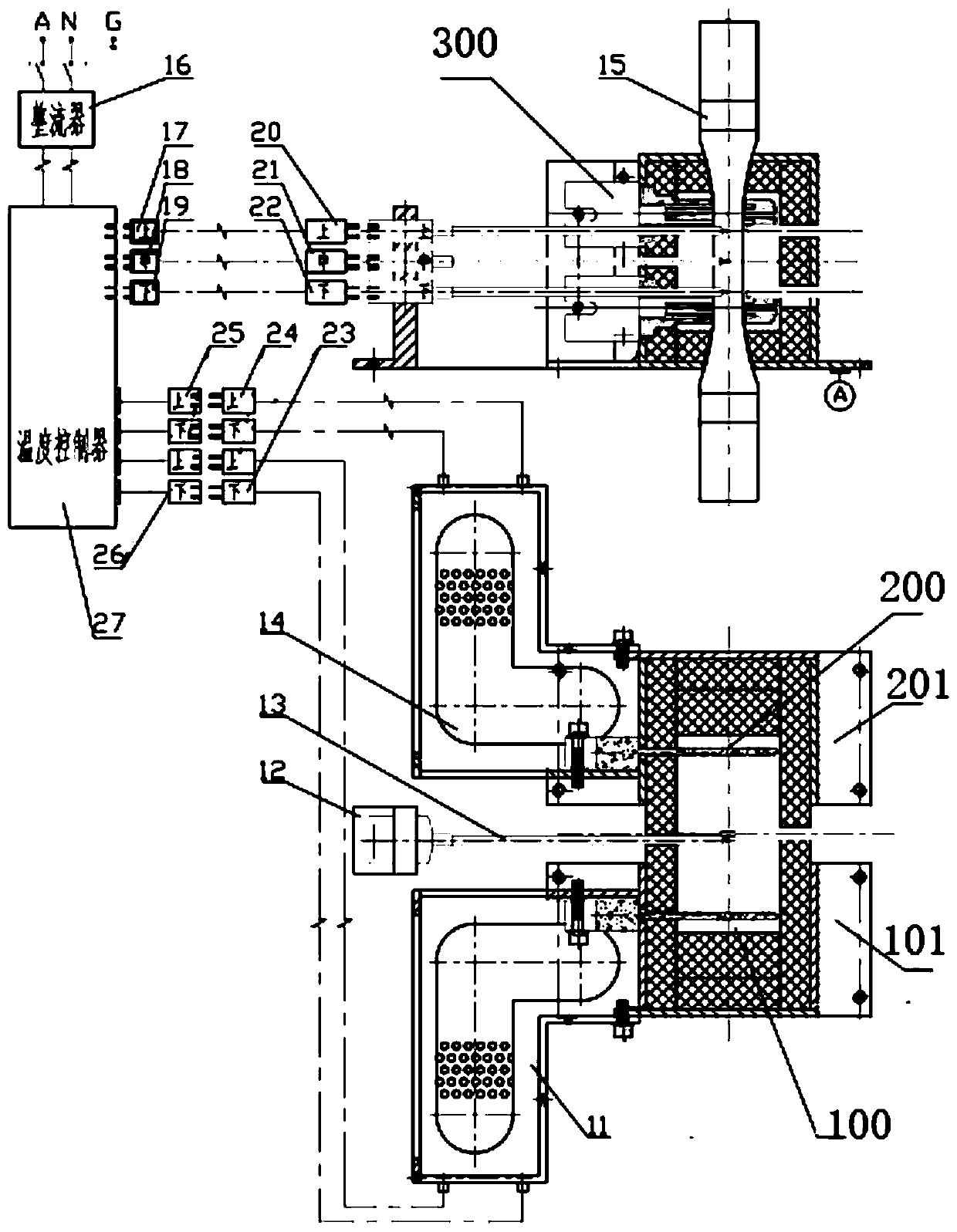

[0028] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

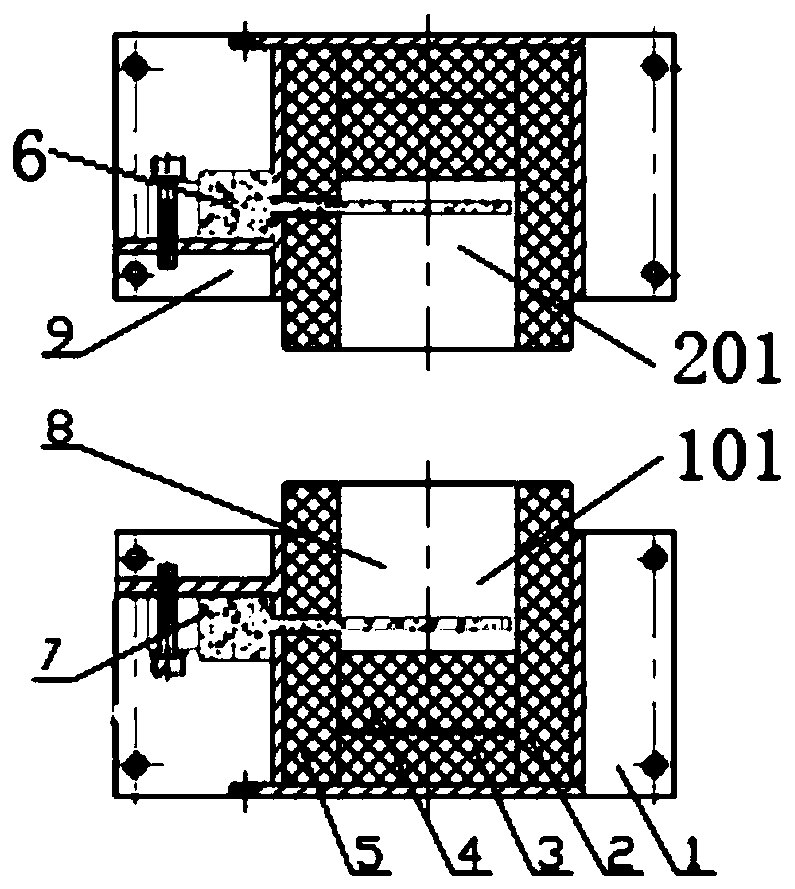

[0029] Such as figure 1 As shown, a high-temperature heating furnace device for testing high-temperature mechanical properties of materials includes a high-temperature furnace 300 , a temperature controller 27 and a rectifier 16 . Such as figure 2 As shown, the high temperature furnace 300 includes a lower furnace body 1 and an upper furnace body 9;

[0030] It also includes a pair of vertically symmetrical ceramic linings, the ceramic linings include a first ceramic block 2, a second ceramic block 5, two third ceramic blocks 8, a fourth ceramic block 3, and a fifth ceramic block 4;

[0031] One of the ceramic linings is pressed into the lower furnace body 1, and the lower furnace heating element 7 is fixed in the lower furnace body 1 to form the lower furnace 101;

[0032] Another ceramic lining is pressed into the upper furnace body 9, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com