Work piece sealing transfer device of vertical heating treatment production line

A transfer device and production line technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of slow heating speed of vacuum heating chamber, uneven furnace temperature, cumbersome structure, etc., to solve the problems of heat treatment, uniform furnace temperature, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

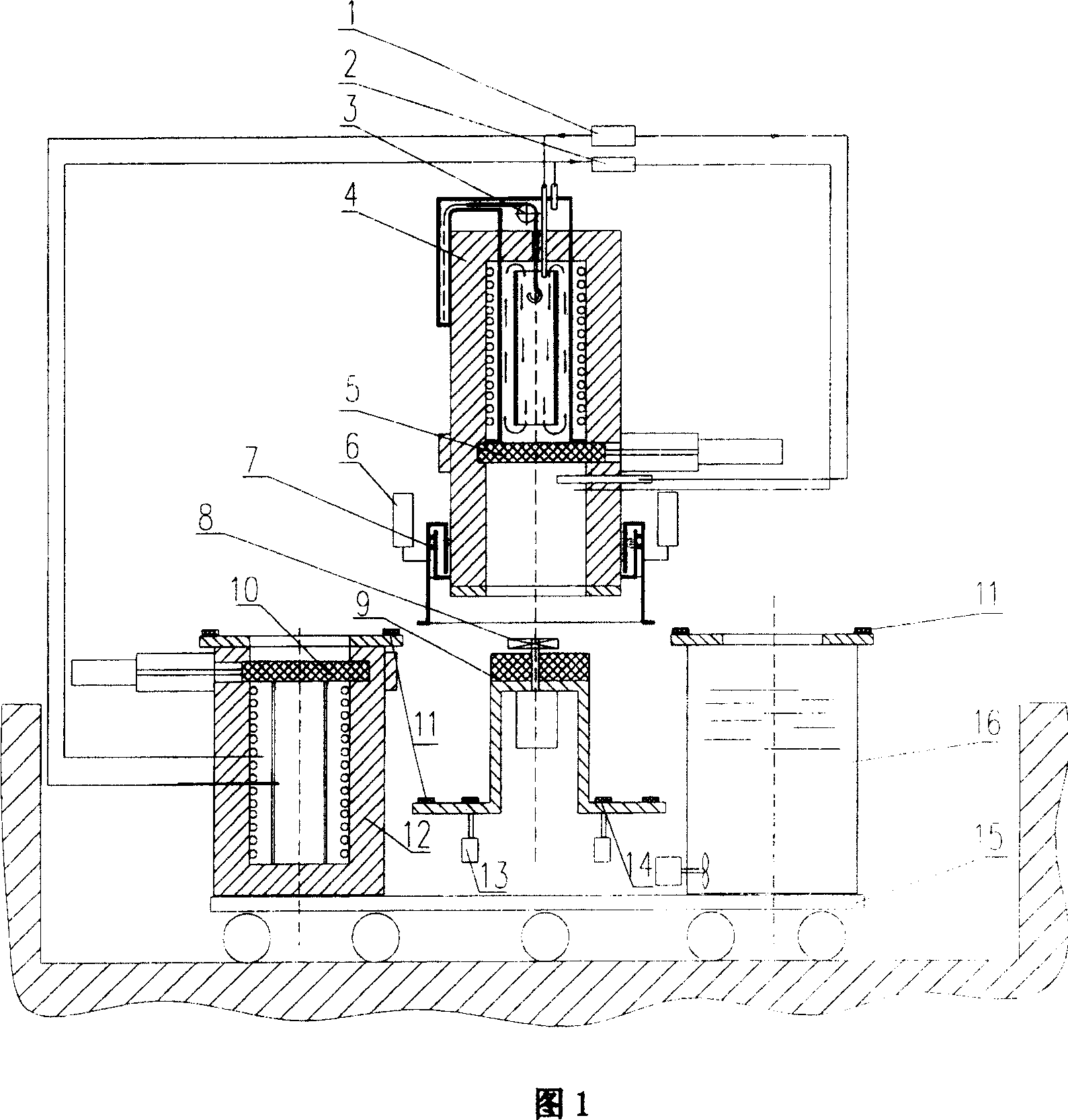

[0017] As shown in Figure 1, the present invention includes: protective atmosphere system 1, vacuum system 2, workpiece lifting mechanism 3, heating furnace 4, heating furnace vacuum heat insulation sealing gate 5, sealing cover lifting mechanism 6, movable sealing cover part 7, fan 8. Heating furnace cover 9, preheating furnace vacuum heat insulation sealing gate 10, butt joint sealing gasket 11, preheating furnace 12, furnace cover lifting mechanism 13, furnace cover inner sealing gasket 14, trolley 15, quenching tank 16, and its connection mode The protective atmosphere system 1 and the vacuum system 2 are respectively connected to the upper and lower parts of the heating furnace 4 and the preheating furnace 12, the workpiece lifting mechanism 3 is arranged on the upper part of the heating furnace 4, and the vacuum heat insulation sealing gate 5 of the heating furnace is arranged on the heating furnace 4 The middle and lower part, the movable sealing cover part 7 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com