Method and device for producing strand-shaped goods

A kind of article and strip technology, which is applied in the direction of flat products, artificial filament physical therapy, application, etc., can solve the problem that the heating device can only realize hot water heating and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

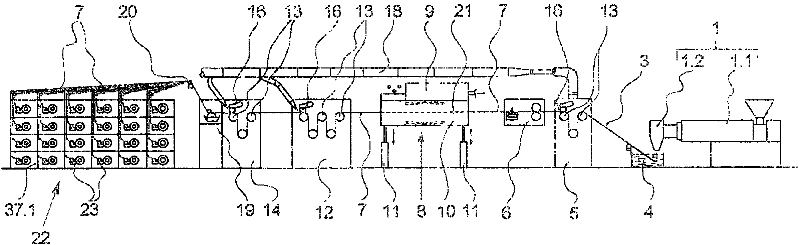

[0025] figure 1 An exemplary embodiment of a device according to the invention for carrying out the method according to the invention is shown schematically in FIG. This embodiment relates to a device for producing small film strips from extruded film.

[0026] For this purpose, a spinning device 1 is formed by an extruder 1.1 and a spinning head 1.2. The spinning head 1.2 comprises continuous extrusion means to extrude a film from the thermoplastic melt supplied through the extruder 1.1. The extruded film 3 here enters a cooling bath 4 arranged below the spinning head 1.2, so that the film 3 solidifies on its surface. The film 3 is guided via a first roller conveyor 5 to a cutting device 6 . For this purpose, the first roller conveyor 5 has a plurality of driven rollers 13 , on the circumference of which the film is guided partially wraparound.

[0027] In the cutting device 6 individual knives cut into the film 3 in order to cut the film sheet into bundles of small film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com