Box-type resistance furnace

A box-type resistance furnace and furnace body technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as affecting production efficiency and insufficient utilization of resources, achieving large loading capacity, enhancing thermal insulation effects, The effect of uniform furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

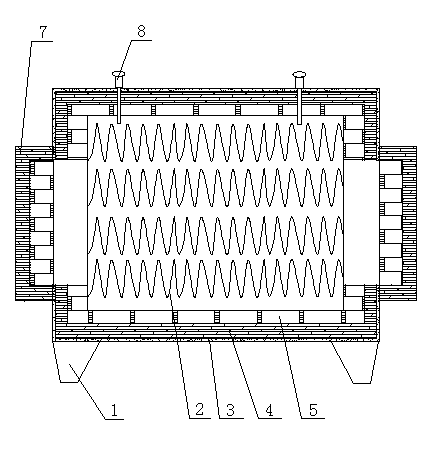

[0016] like figure 1 As shown, the present embodiment provides a box-type resistance furnace, including a furnace frame 1, a furnace body and a heating element 2, the furnace body is fixed on the furnace frame 1, a furnace is provided inside the furnace body, and the furnace body The body includes a furnace shell 3, an insulation layer 4 and a refractory layer 5 arranged sequentially from the outside to the inside, and the refractory layer 5 adopts a density less than 1100kg / m 3 , preferably 900kg / m 3 refractory bricks, the insulation layer 4 is made of aluminum silicate refractory fiber, the space between the furnace shell 3 and the insulation layer 4 is filled with frog stone powder, and the heating element 2 adopts a wave-shaped resistance band, and the resistance band is evenly arranged on the On the refractory layer 5 of the furnace bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com