The Injection Method to Ensure High Bituminous Coal Ratio

A high-bituminous coal and flue gas furnace technology, applied in the field of smelting, can solve the problems that have not been discussed about the water content of pulverized coal at the outlet of the speed mill and the water content of raw coal injected, and achieve the effect of increasing the temperature of the exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific embodiments.

[0021] A kind of injection method of high bituminous coal ratio of the present invention comprises the following steps:

[0022] A) A first test sampling hole is set at the inlet position of the medium-speed mill;

[0023] B) adopt an infrared thermometer to monitor the flue gas temperature on the first test sampling hole set in step A);

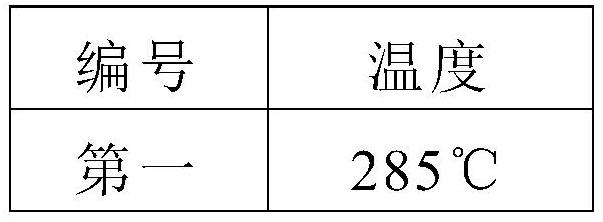

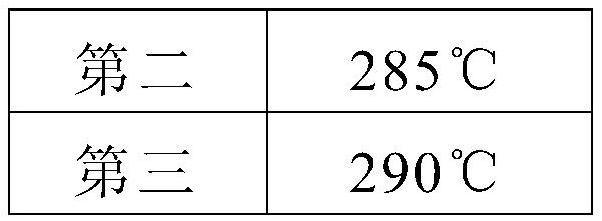

[0024] C) When the temperature of the flue gas at the first test sampling hole is lower than the preset temperature, increase the temperature of the flue gas in the hot blast stove and the flue gas furnace until the temperature of the flue gas at the first test sampling hole is higher than the preset temperature. The temperature was set at 280 to 300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com