Heat capacity expansion system for garbage

A technology of waste and heat energy, applied in the field of waste heat energy capacity expansion system, can solve the problems of insufficient heat energy, combustion exhaust gas emission, no economic benefits, etc., and achieve the effect of reducing the probability of generation, increasing the low-level calorific value, and improving the degree of availability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

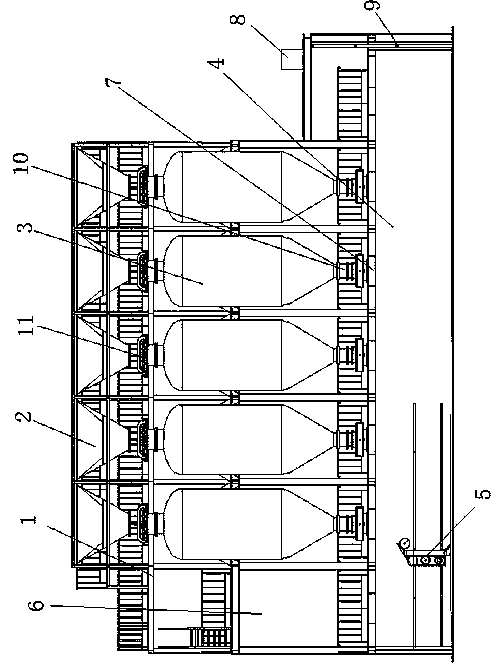

[0011] Embodiment: A garbage thermal capacity expansion system (see the accompanying drawings), which includes a carrying platform 1, which is a loading device 2, a digestion tank 3, a processing chamber 4, and a capacity-increasing garbage conveying and discharging device 5 And the steel structure frame platform of the hydraulic power control system 6, the carrying platform 1 integrates the above-mentioned various functional equipment together to form a complete garbage heat capacity expansion system. The upper part of the carrying platform 1 is provided with a feeding device 2, the feeding device 2 is a conical structure with a cone angle of less than 60 degrees, and the number of feeding devices 2 can be one or evenly distributed according to the needs; the carrying platform The middle part of 1 is provided with a digestion tank 3, the number of the digestion tank 3 is the same as that of the feeding device 2, and each feeding device 2 is connected to the digestion tank 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com