Heat accumulating type steel ladle baking system capable of remarkably reducing NOX (nitrogen oxide) and baking method

A baking method and regenerative technology, applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve problems such as pollution and large pollutant emissions, and achieve cost reduction, uniform furnace temperature, and smoke exhaust. The effect of temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

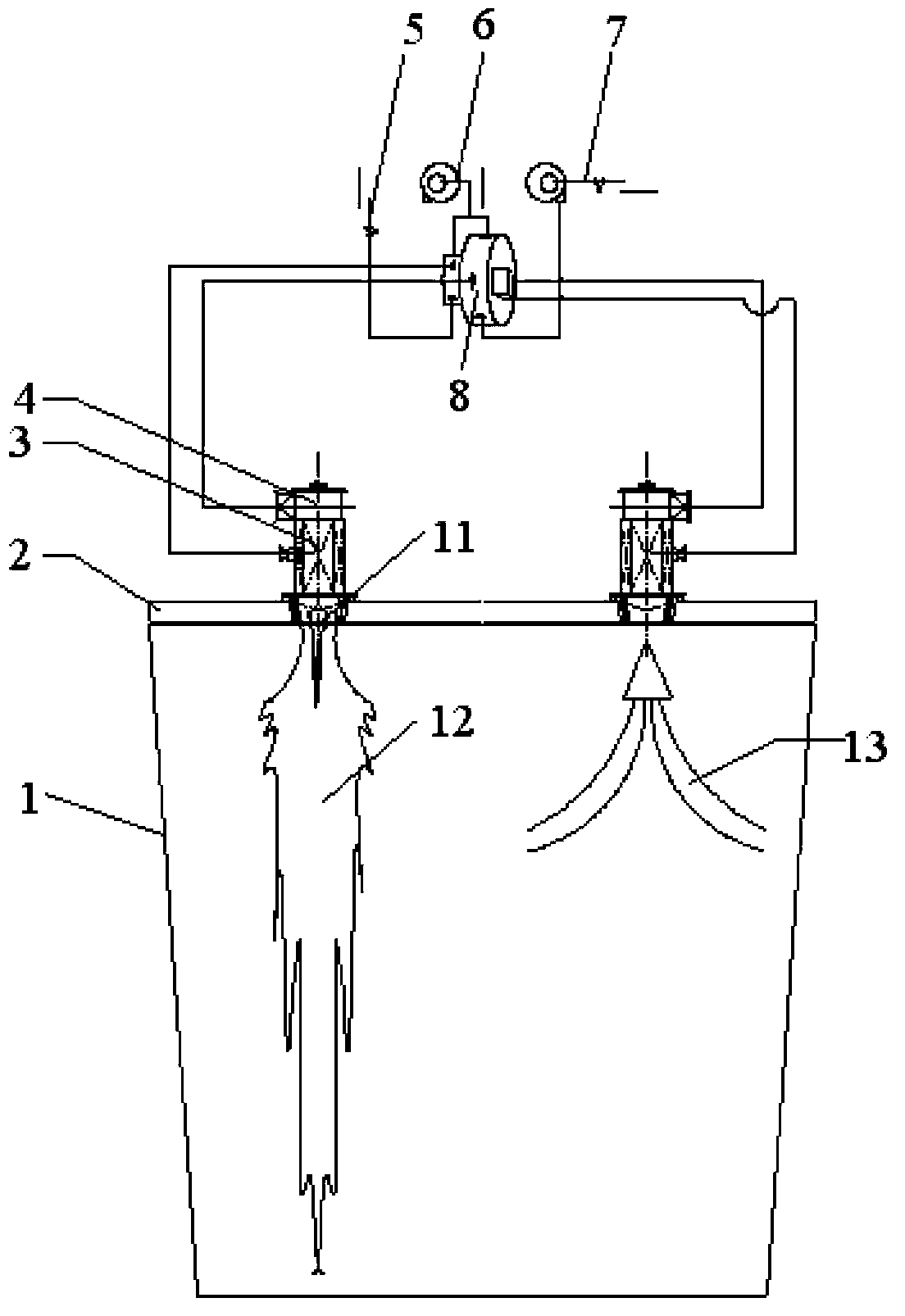

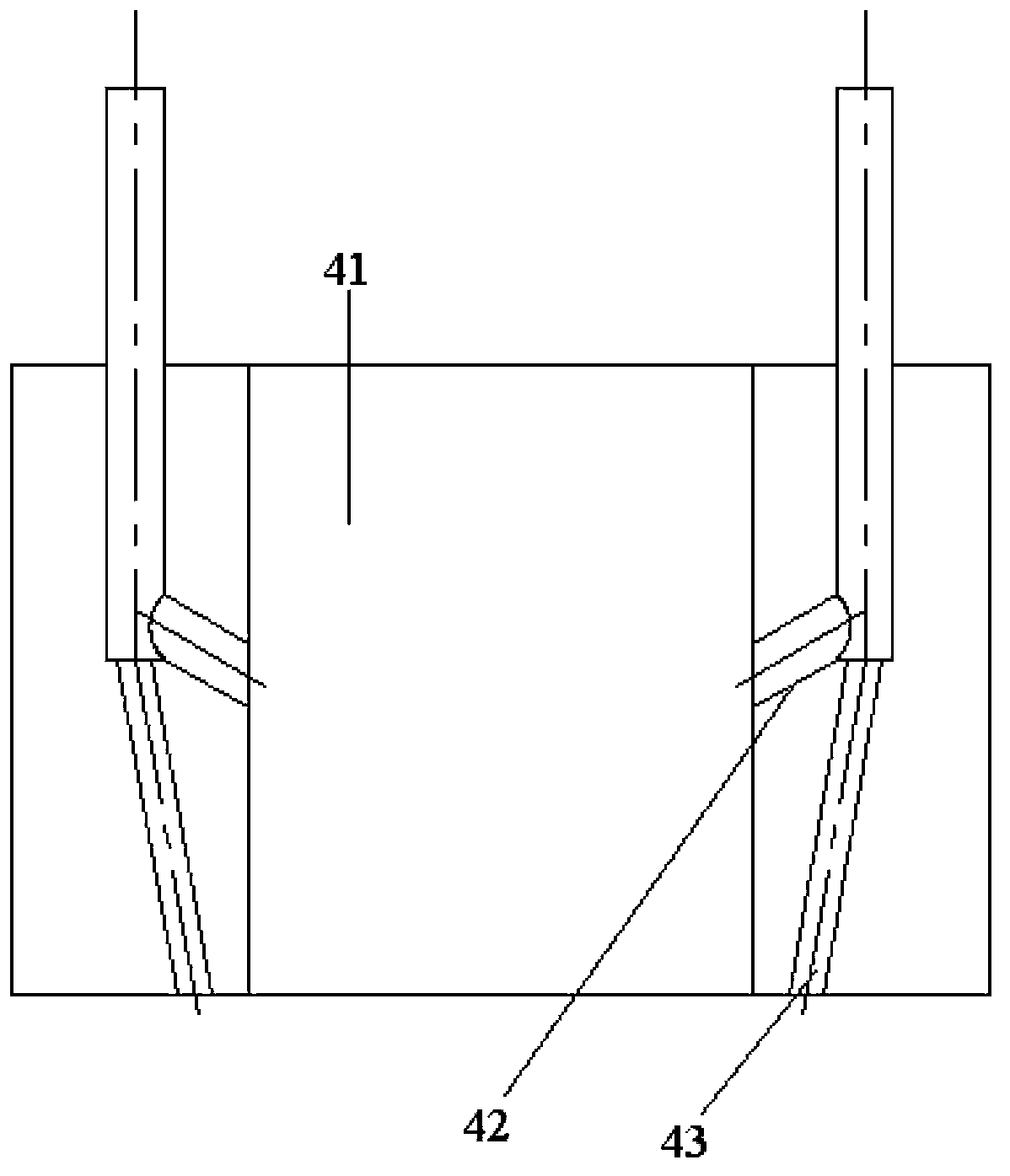

[0026] The present invention adopts a combustion method combining regenerative combustion and rich-lean combustion, which saves energy and reduces NO X The principle of emission is as follows.

[0027] As far as the regenerative combustion method is concerned, the temperature in the furnace is very uniform and the fuel is fully burned, which can greatly reduce the exhaust gas temperature from above 1000°C to below 150°C, fully recover heat, improve production and the surrounding environment, and reduce The heat loss of the flue gas is reduced, and the combustion rate of the combustion is increased, which can save energy and prolong the service life of the ladle.

[0028] As far as the rich-lean combustion method is concerned, it reduces NO by reducing the combustion temperature X production, thereby reducing NO X emissions. The reduction of the combustion temperature comes from two reasons: on the one hand, the excess air acts as a dilution effect, and on the other hand, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com