Ceramic railing with high weatherability, and preparation method thereof

A high weather resistance, ceramic technology, applied in the direction of fences, clay products, other household appliances, etc., can solve the problems of temperature gradient in unfavorable firing zone, uneven air flow in kiln, prolonging firing cycle, etc., and achieve improved frost resistance And resistance to rapid cooling and rapid heating, reduce mining, and reduce the effect of firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

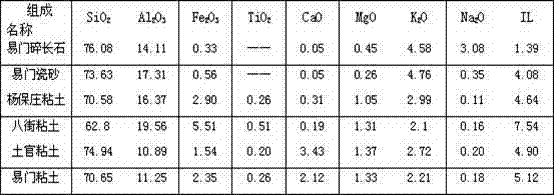

Examples

Embodiment 1

[0037] Types of raw materials weight Yimen crushed feldspar 220kg Yimen Porcelain Sand 442kg Wuding Kaolin 664 kg Eight Street Clay 2250kg Water glass, ceramic thinner, sodium metasilicate for ceramics, ceramic grinding aid 110kg polyvinyl alcohol, glycerin 3.68kg

[0038] Follow these steps to produce:

[0039] ① Coarsely crush the hard feldspar and kaolin in the above raw materials, and optimize the ratio with porcelain sand and soft clay after the particle size is 120 mesh;

[0040] ② The mixture obtained in step ① is sent to a ball mill for ball milling until the particle size of the powder is 140 mesh;

[0041] ③ The above-mentioned powder is sieved through a sieve to remove impurities, and the sieve is 170 meshes;

[0042] ④ The powder after impurity removal is subjected to mud pressing and rough refining, and then it is placed in a room with no air, and it is aged for 24 hours under a certain temperature and hum...

Embodiment 2

[0051] Types of raw materials weight Yimen crushed feldspar 300kg Yimen Porcelain Sand 500kg Lincang Kaolin 200kg Yimen Clay 2580kg Water glass, ceramic thinner, sodium metasilicate for ceramics, ceramic grinding aid 110kg polyvinyl alcohol, glycerin 18.45kg

[0052] Follow these steps to produce:

[0053] ①The hard feldspar and kaolin in the above-mentioned raw materials are coarsely crushed, and the particle size is 100 meshes, and the optimized ratio is carried out with the porcelain sand and soft clay;

[0054] ② The mixture obtained in step ① is sent to a ball mill for ball milling until the particle size of the powder is 150 mesh;

[0055] ③ The above-mentioned powder is sieved through a sieve to remove impurities, and the sieve is 180 meshes;

[0056] ④ The powder after impurity removal is subjected to mud pressing and rough refining, and then it is placed in a room with no air, and it is aged for 24 hours under...

Embodiment 3

[0065] Types of raw materials weight Yimen crushed feldspar 300kg Yimen Porcelain Sand 500kg Lincang Kaolin 200kg Yang Baozhuang Clay 2580kg Water glass, ceramic thinner, sodium metasilicate for ceramics, ceramic grinding aid 100kg polyvinyl alcohol, glycerin 7.36kg

[0066] Follow these steps to produce:

[0067] ① Coarsely crush the hard feldspar and kaolin in the above-mentioned raw materials, and optimize the ratio with porcelain sand and soft clay after the particle size is 110 mesh;

[0068] ② The mixture obtained in step ① is sent to a ball mill for ball milling until the particle size of the powder is 150 mesh;

[0069] ③ The above-mentioned powder is sieved through a sieve to remove impurities, and the sieve is 170 meshes;

[0070] ④The powder after impurity removal is subjected to mud pressing and rough refining, and then placed in a room with no air, maintaining a certain temperature and humidity environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com