PLC controlled intelligence well-type electric furnace

An electric furnace and well-type technology, which is applied in the field of control or adjustment of the heat treatment process of the well-type furnace, can solve the problems of difficult adjustment of the power output of the load main circuit, failure of closed-loop control, waste product quality accidents, etc., to achieve high automation and low heating temperature rise Fast, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

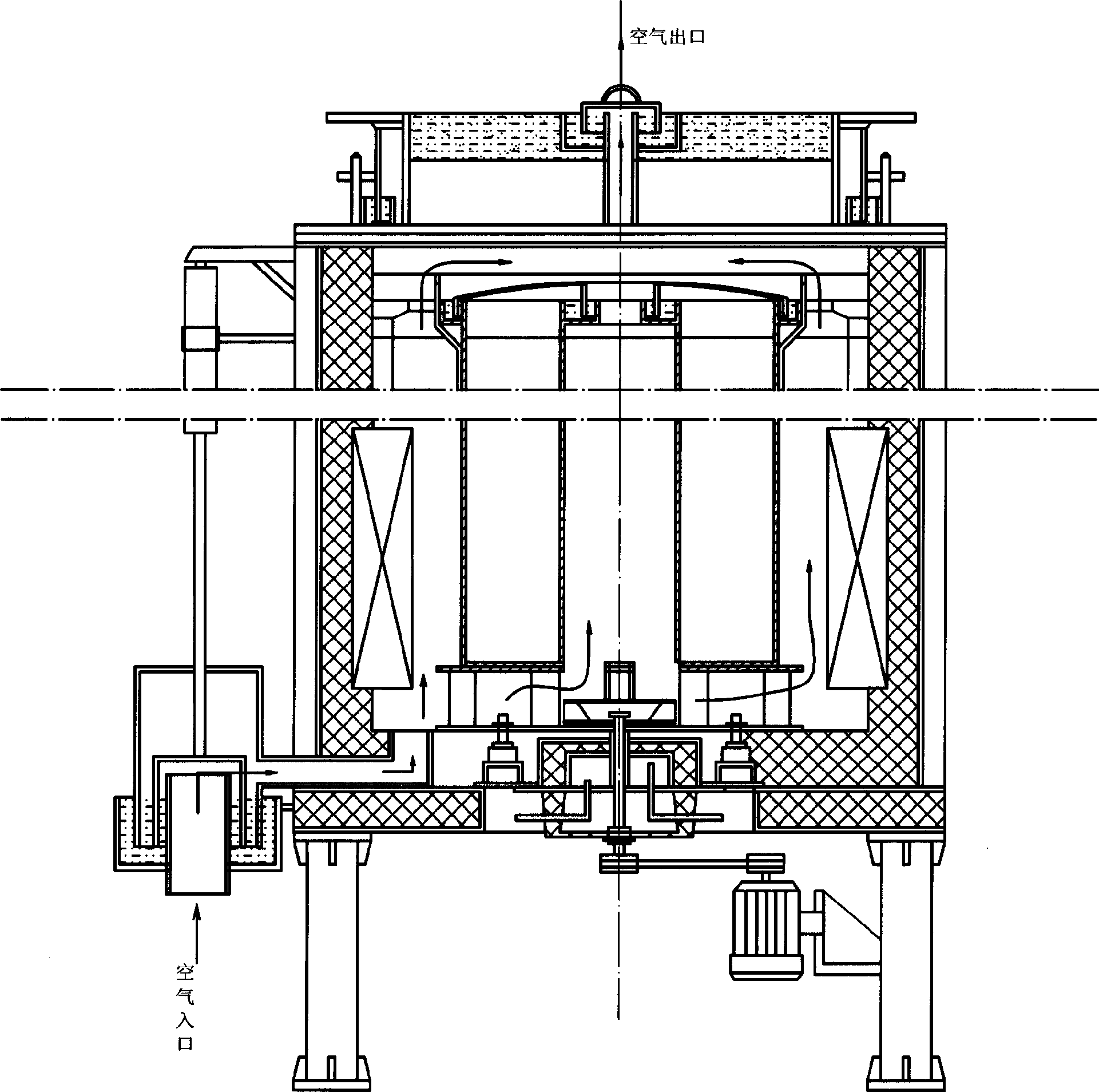

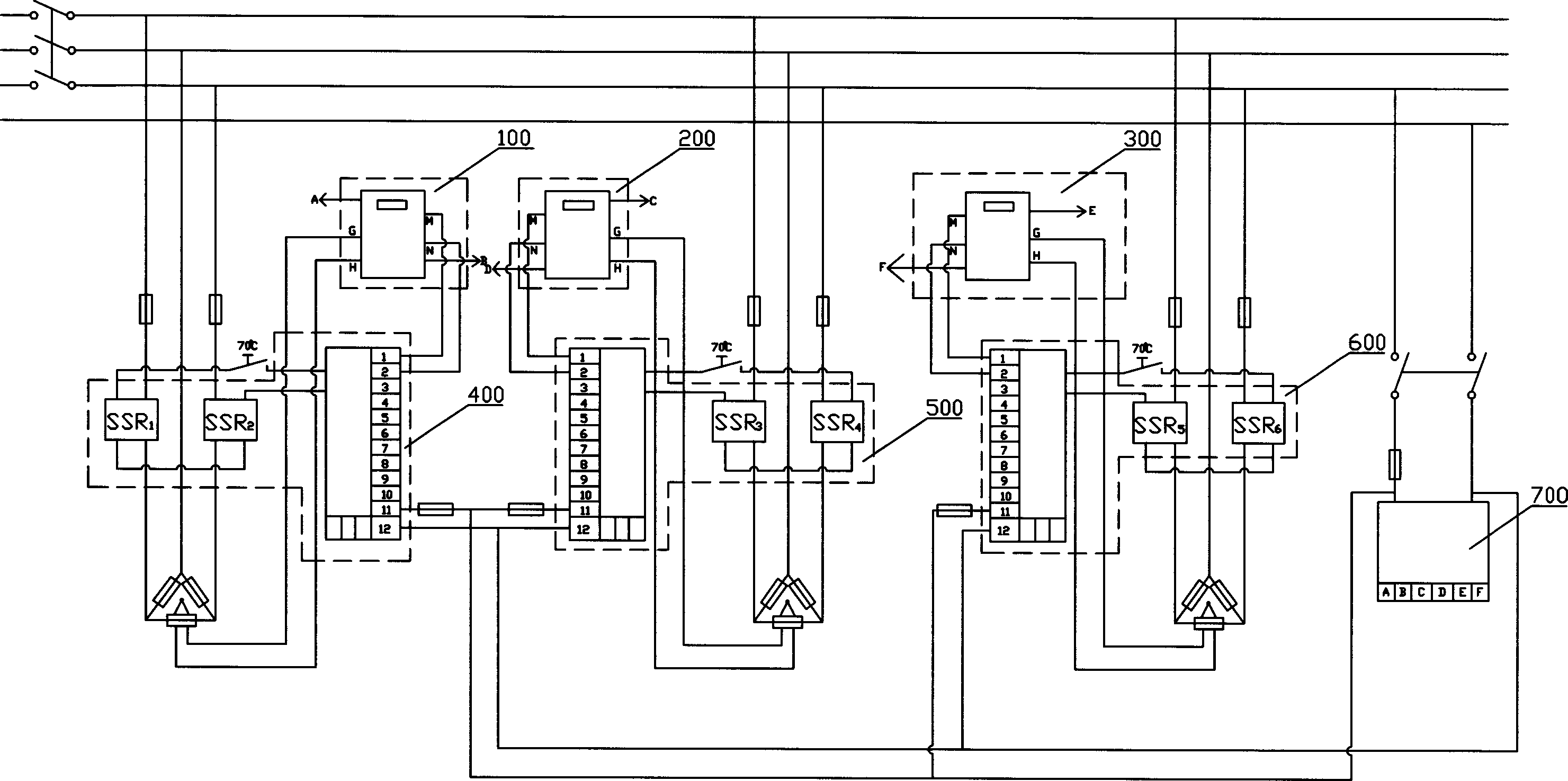

[0017] Such as figure 1 and figure 2 As shown, a PLC-controlled intelligent well-type electric furnace includes a furnace body, a furnace cover and a resistance heating body. The resistance heating body is connected to the power supply in a star or angle shape. PLC-controlled system, the system implements partitioned temperature control for the main circuit, and its control circuit is composed of three programmable PID regulators, three integrated three-phase power regulators and a temperature control meter connector, each The temperature control area is equipped with thermocouples, which are connected to the programmable PID regulator through the compensation circuit. The external input terminal of the regulator is connected to the temperature control meter connector, and its output terminal is connected to the input terminal of the integrated three-phase power regulator. , and connected in series and parallel with the main circuit through the temperature control switch and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com