Energy-saving mesh belt type air isothermal furnace

A mesh-belt-type, energy-saving technology, applied in the field of heating furnaces, can solve the problems of poor quality of high-temperature tempering and increased labor costs, and achieve the effects of long service life, uniform heating, and good uniformity of furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

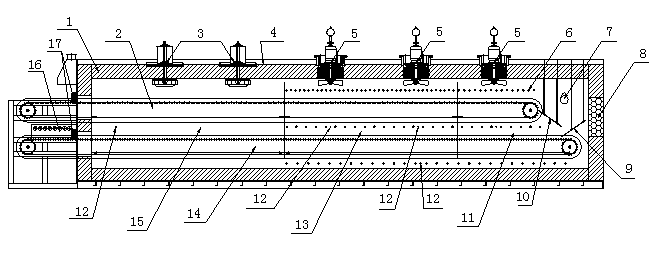

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 An energy-saving mesh-belt type air isothermal furnace is shown, which includes an insulating shell 1, and the insulating shell 1 adopts high-grade insulating cotton to ensure the minimum heat loss and save energy consumption; the insulating shell 1 is divided into isothermal zones 11. The heating zone 13 and the heat exchange zone 15 are equipped with a feed transmission mesh belt 2 above the interior of the heat preservation shell 1, and a discharge transmission mesh belt 14 is provided below the interior of the heat preservation shell 1. The side is provided with feed inlet and discharge port, is provided with heater 6 in isothermal zone 11 and heating zone 13, and the length of feeding conveying net belt 2 is less than the length of discharging conveying net belt 14 in isothermal zone 11, in A high-temperature circulation fan 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com