Novel heated-air circulation tempering furnace

A hot air circulation and tempering furnace technology, which is applied to heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of changing length, inconvenient installation and maintenance, etc., and achieve the effect of changing length, uniform hot air circulation, and uniform furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

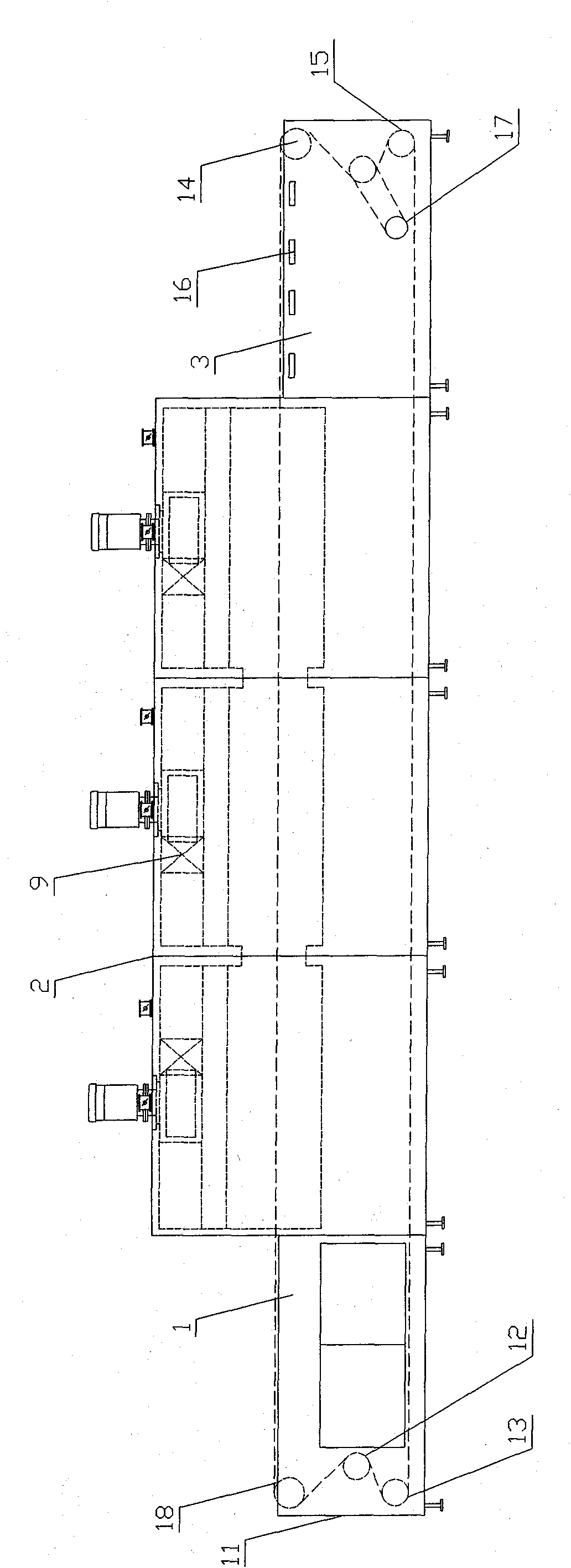

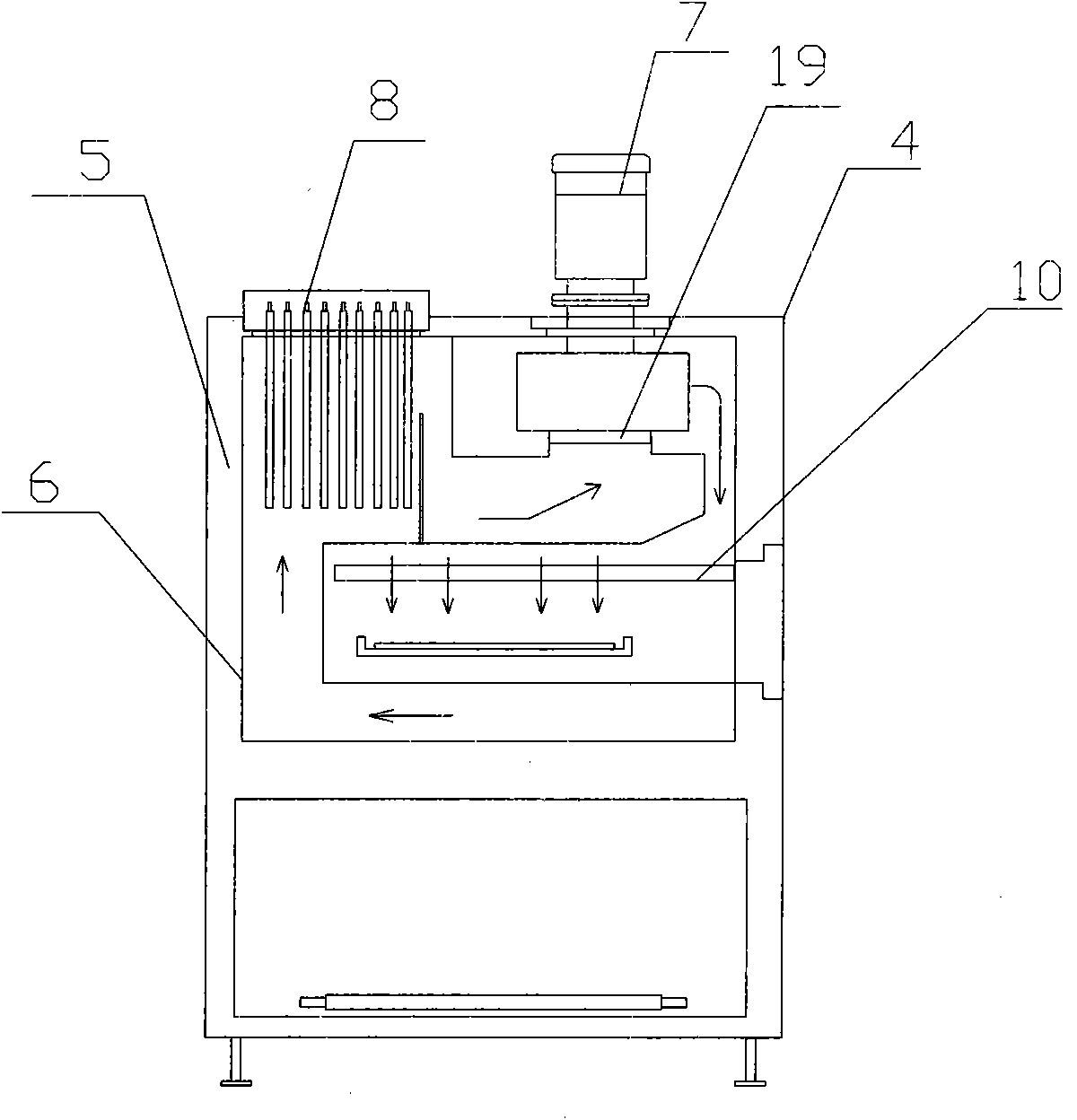

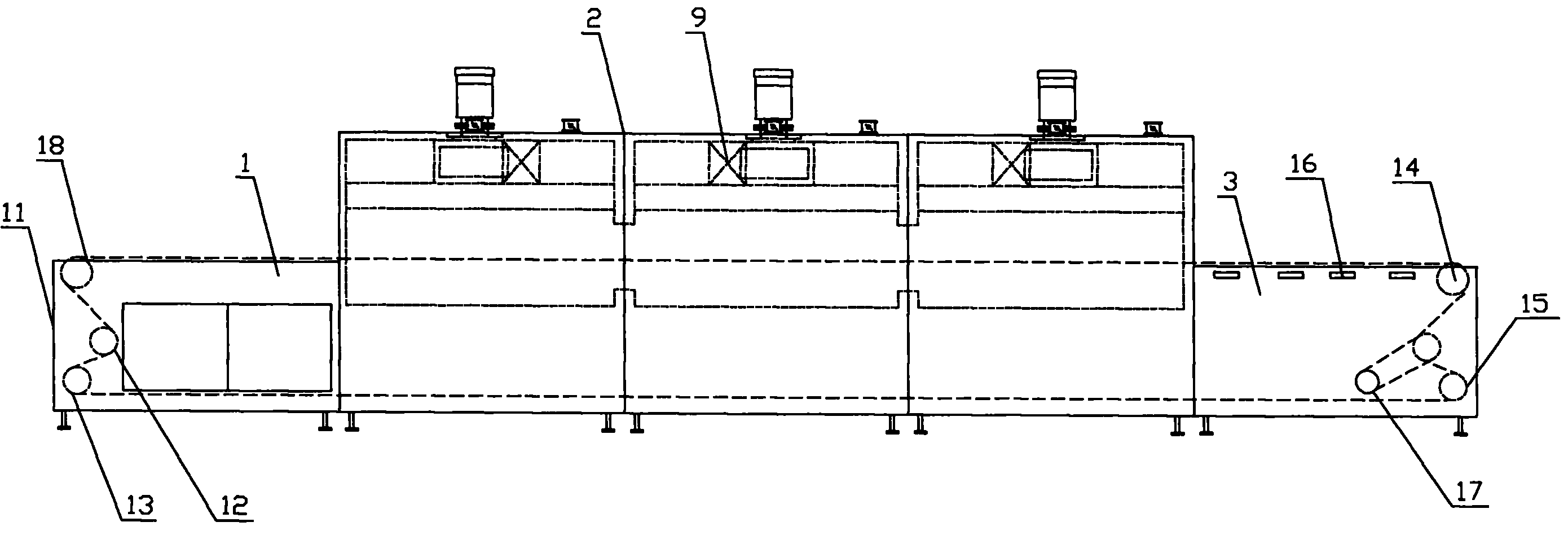

[0013] Such as figure 1 A new type of hot air circulation tempering furnace shown in ~3 includes a feeding platform 1, a furnace body 2, and a discharging platform 3. The furnace body 2 includes an external furnace shell 4, a furnace body insulation layer 5, an inner container 6 and The fan 7 and the heating element 8 installed on the furnace body 2, the fan 7 is provided with an air suction port 19 and an air outlet 10, and a heat conduction system 10 is provided below the air outlet 9, which can adjust the position of the hot air to determine the hot air The hot air passes through the workpiece from top to bottom and passes through the mesh belt 18. The air duct on one side of the furnace body passes through the centrally arranged heating element 8 and is sucked by the fan suction port 19, and then the hot air is passed through the furnace through the air outlet 9 of the fan. The hot air guide system 10 evenly blows the wind to the workpiece to ensure the uniformity of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com