Fast cooling method for lithium iron phosphate steel belt type reducing furnace

A technology of lithium iron phosphate and lithium phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of small output, no rapid cooling, difficult process adjustment and quality control, etc., to achieve large output, Facilitate process adjustment and quality control, facilitate installation, maintenance and dismantling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

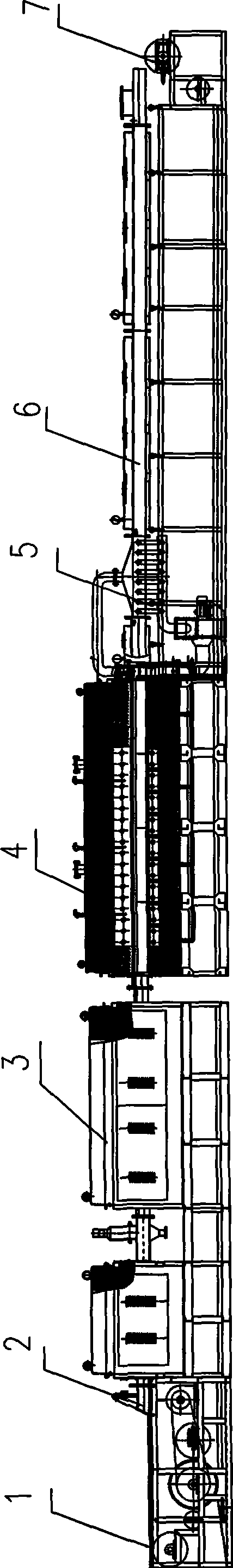

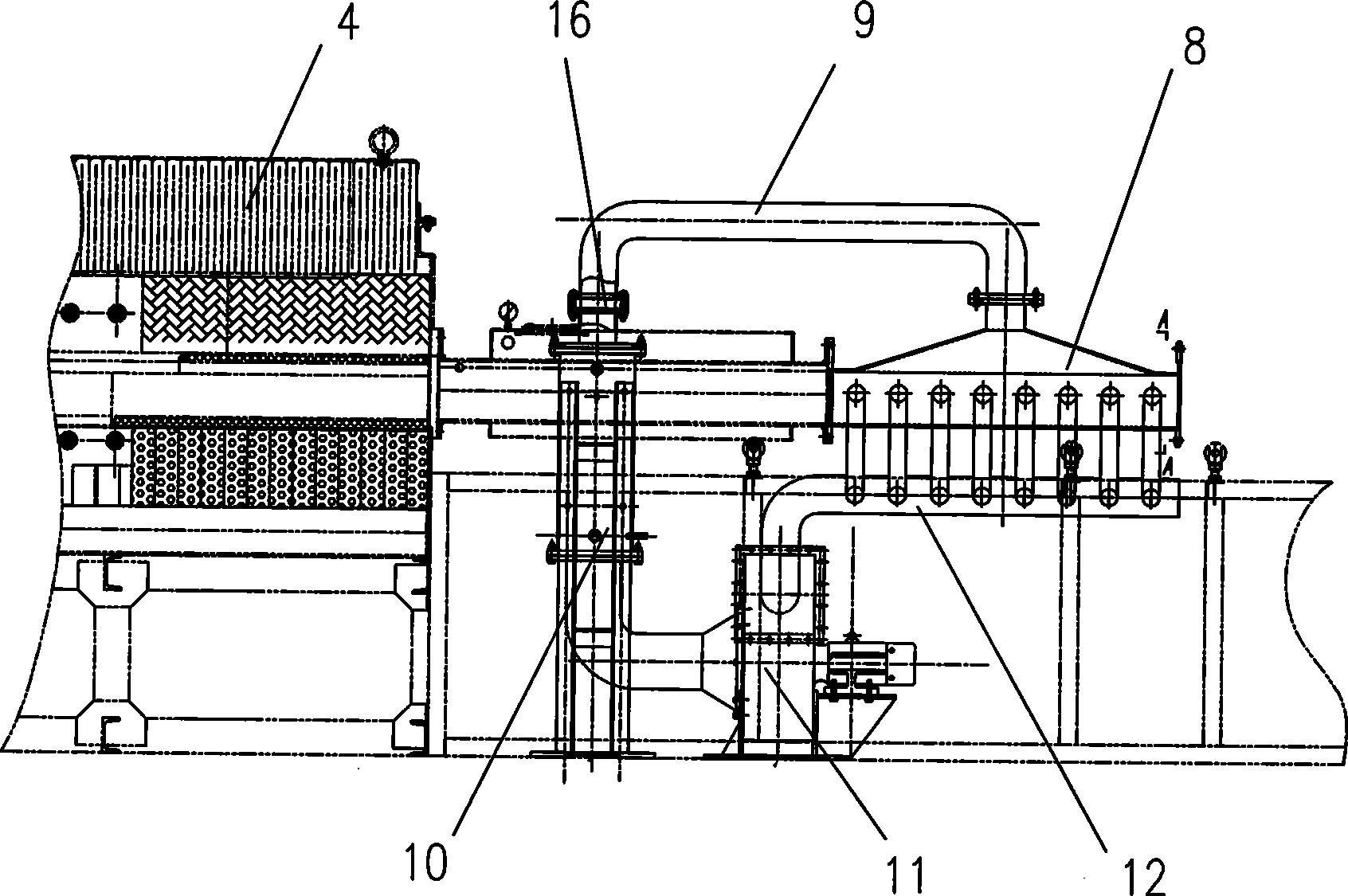

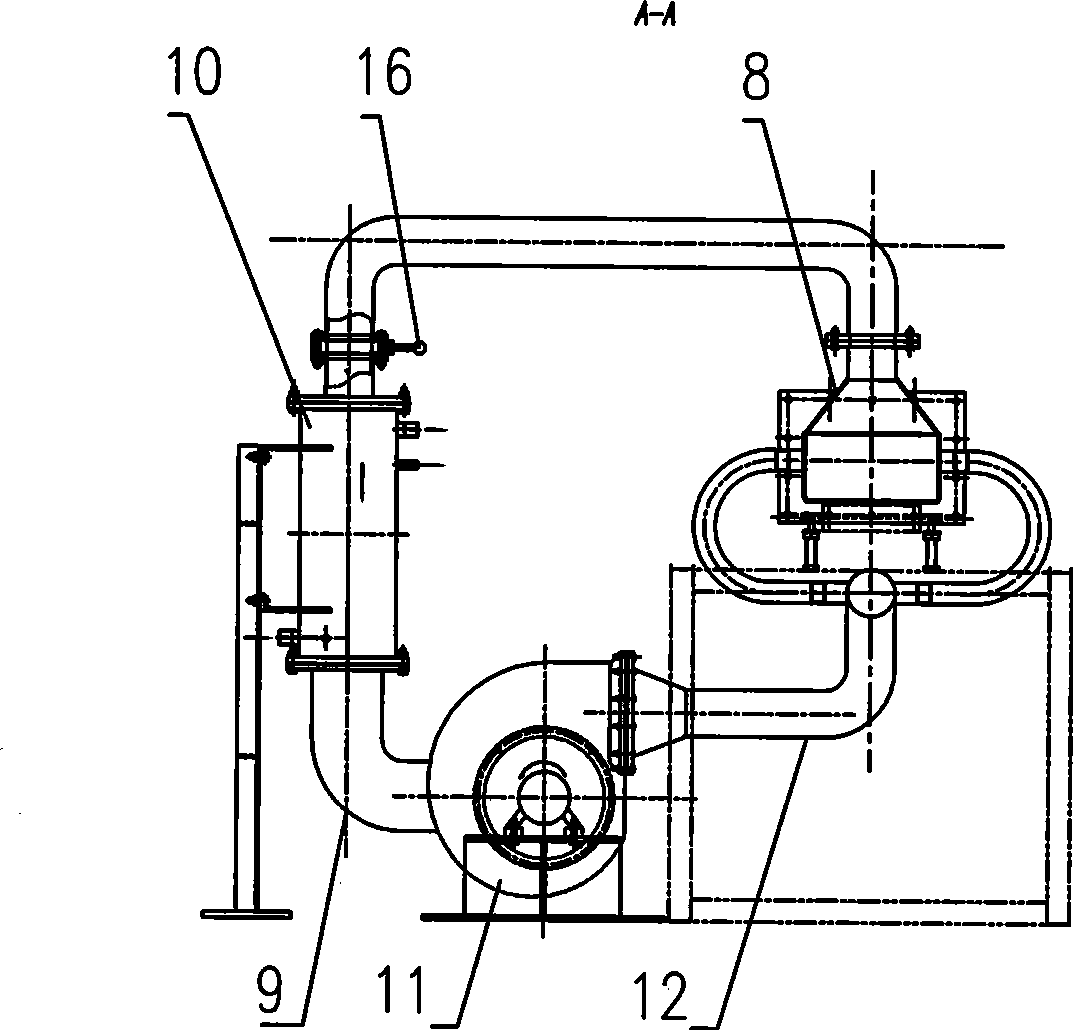

[0020] see Figure 5 , lithium iron phosphate is added to the steel belt of the steel belt reduction furnace through the feeding part 2, and then sintered through the pre-sintering section 3 and the sintering section 4, and then enters the rapid cooling device 5 for rapid cooling, and the cooling rate is: 8.8 ° C / min, the lithium iron phosphate is rapidly cooled by the rapid cooling device 5 and then discharged through the discharge section 6 to complete the overall sintering process.

[0021] Thermocouple measurement length: 11 meters; running time: 193 minutes; available network speed: 11000 / 193 = 57mm / min; time required to run 1 meter: 1000 / 57 = 17.54min; start fast cooling length: 11 -1.2=9.8 meters, required time: 9800 / 57=172 minutes, the length of fast cooling end is: 11-0.2=10.8 meters, required time: 10800 / 57=189.5min;

[0022] The corresponding temperature at the beginning of rapid cooling is: 266°C; the temperature at the end of rapid cooling is 111°C; the cooling...

Embodiment 2

[0024] see Image 6 , lithium iron phosphate is added to the steel belt of the steel belt reduction furnace through the feeding part 2, and then sintered through the pre-sintering section 3 and the sintering section 4, and then enters the rapid cooling device 5 for rapid cooling, and the cooling rate is: 15.8 ° C / min, the lithium iron phosphate is rapidly cooled by the rapid cooling device 5 and then discharged through the discharge section 6 to complete the overall sintering process.

[0025] Mesh belt length: 11 meters; running time: 191 minutes; available network speed: 11000 / 191=57.6mm / min; time required to run 1 meter: 1000 / 57.6=17.36min; initial network speed: 85mm / min; after 20 minutes, adjust to: 54mm / min; initial net speed running length: 85*20=1700mm, start fast cooling time: (10800-1700) / 54=168.5min; fast cooling end time: 168.5+ 1000 / 54=187min;

[0026] The corresponding temperature at the beginning of rapid cooling is: 388 degrees; the temperature at the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com