Aluminium alloy single-bar rapid heating stove

A rapid heating, aluminum alloy technology, applied in the field of heating furnace, aluminum alloy single rod rapid heating furnace, can solve the problems of heating, shutdown failure, poor temperature uniformity, etc., to achieve uniform furnace temperature, low failure rate, high thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

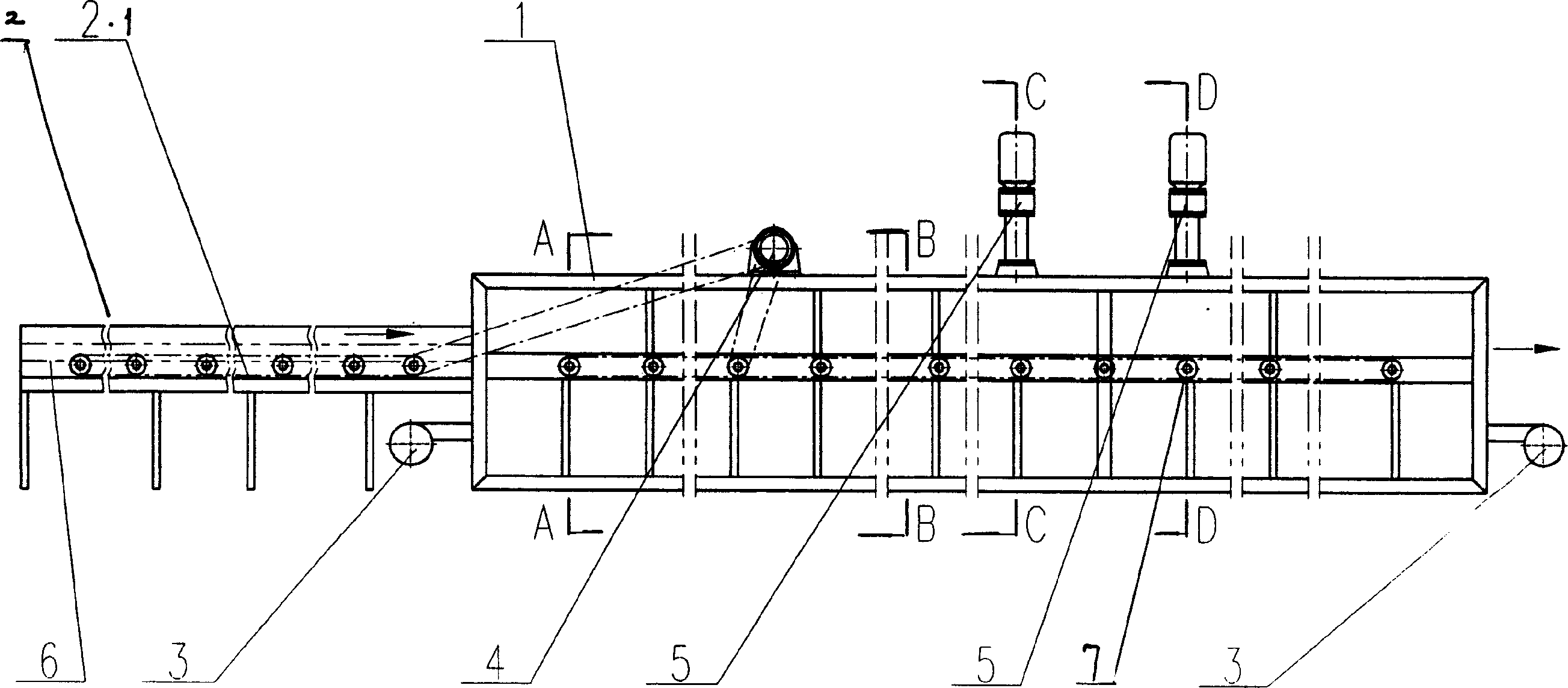

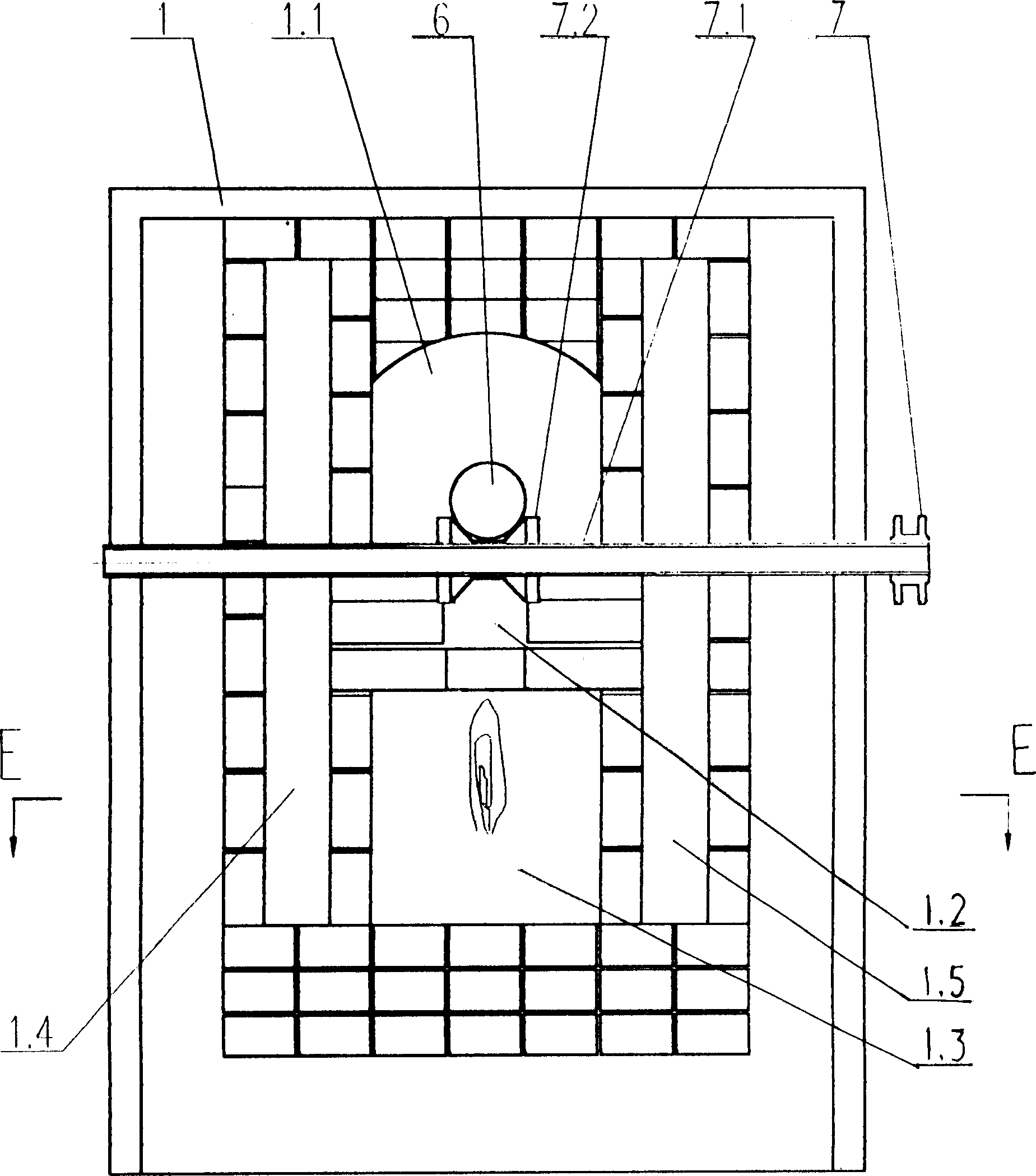

[0017] see figure 1 , figure 1 It is an aluminum alloy single rod rapid heating furnace. It is mainly composed of a furnace body 1, a feeding rack 2, a burner 3, a chain system device 4, a circulating fan 5 and a transmission roller table 7. The feeding frame 2 is placed on the rear side of the furnace body 1 . The feeding frame 2 is provided with a feeding roller table 2.1. An aluminum alloy bar stock 6 is placed on the feeding roller table 2.1. Rely on the feeding roller table 2.1 to send the aluminum alloy bar 6 into the transmission roller table 7 in the heating chamber of the furnace body for heating.

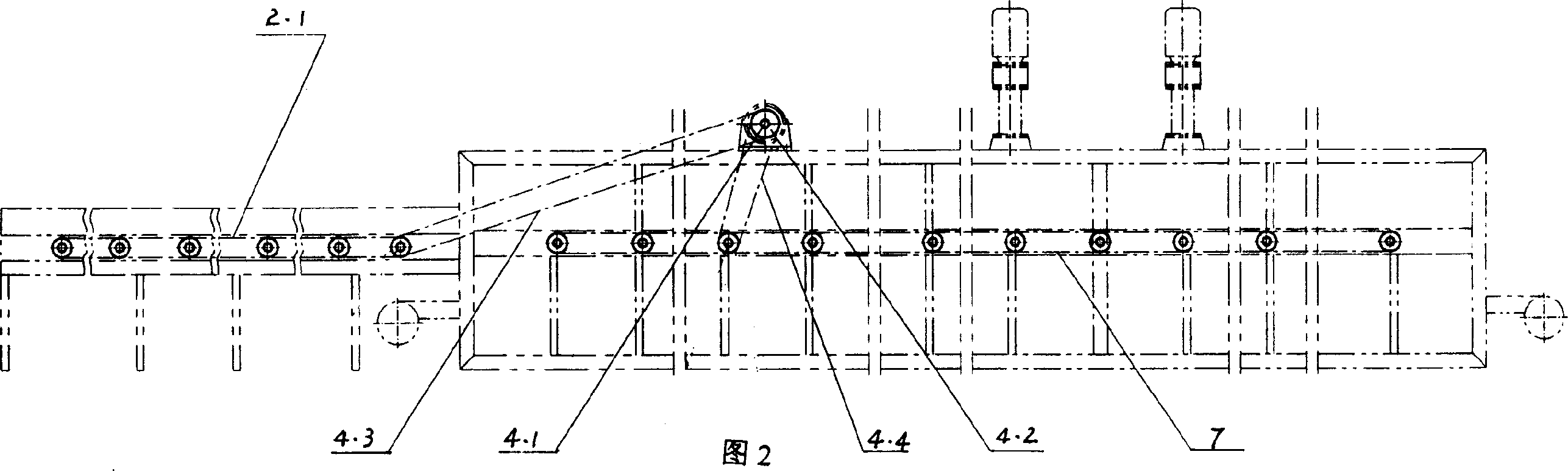

[0018] Referring to Fig. 2, the feeding roller table 2.1 on the feeding rack 2 and the transmission roller table 7 in the furnace body heating chamber 1.1 are driven by the same chain transmission device 4. The motor 4.1 of the chain drive 4 is installed on the top of the furnace body 1 . The sprocket 4.2 on the power shaft of the motor 4.1 transmits the power to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com