Construction hoist standard knot coating production line and coating process

A technology for construction elevators and coating production lines, which is applied in the direction of surface coating liquid devices, coatings, spraying devices, etc., which can solve problems such as uneven quality, high labor costs, and serious pollution, so as to improve internal quality, High recovery efficiency and uniform furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

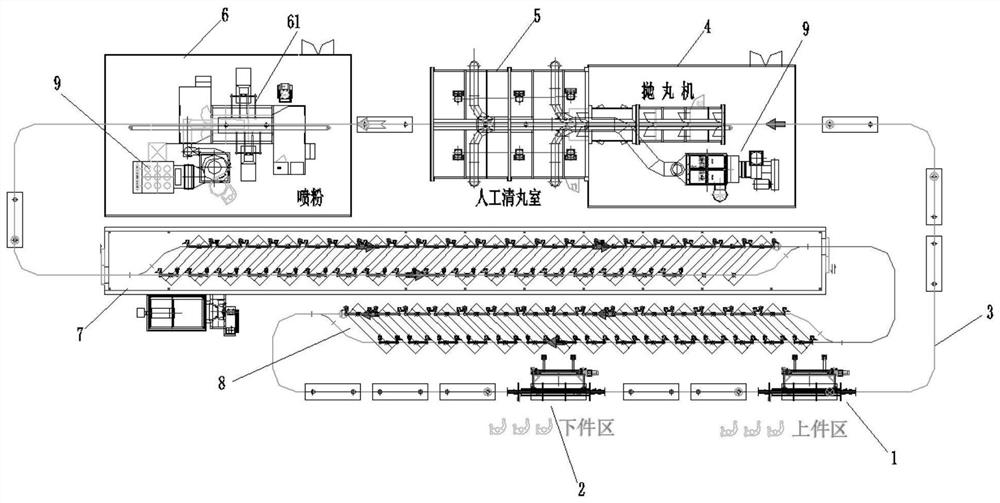

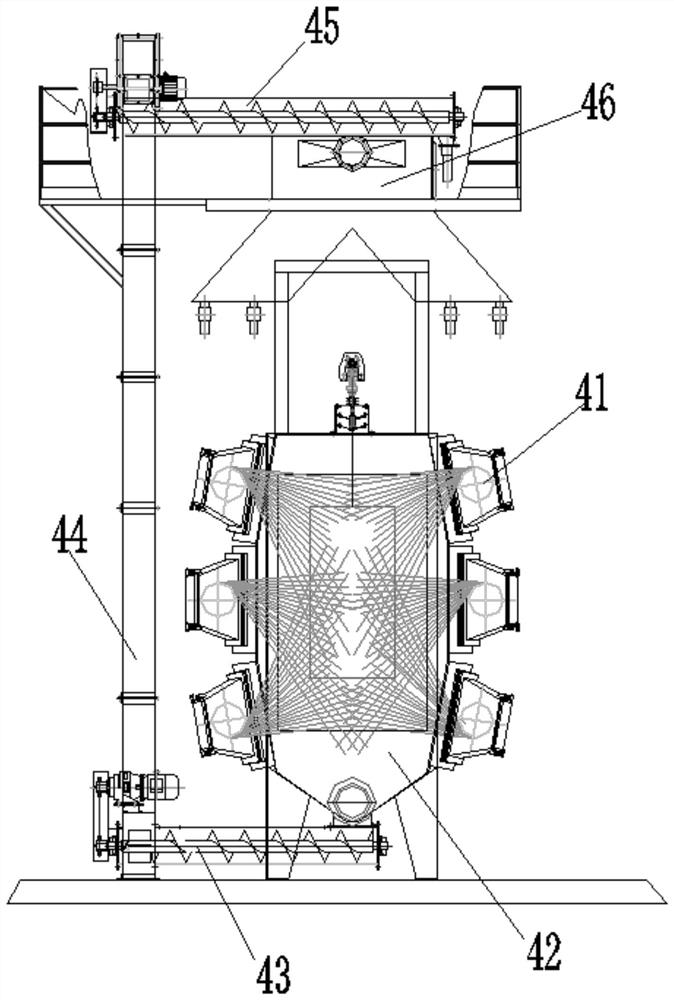

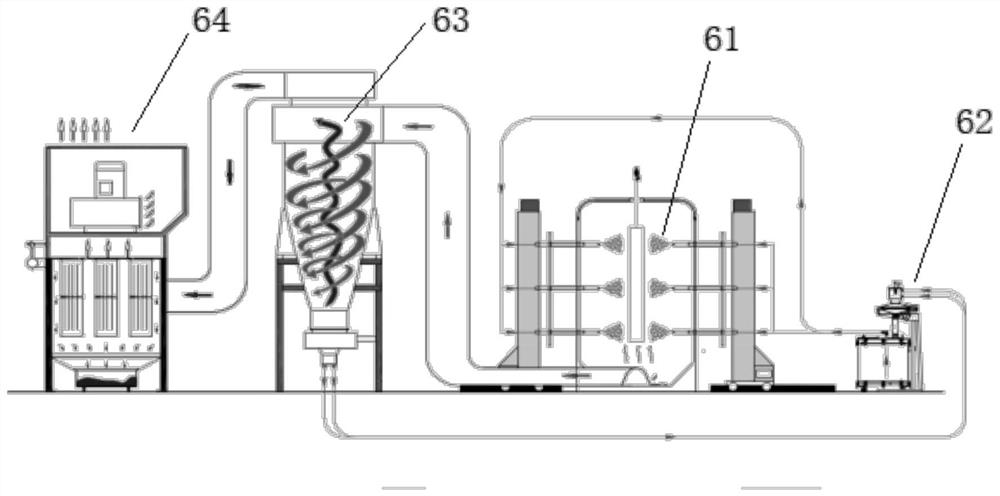

[0041] Such as figure 1 As shown, a standard section coating production line of a construction elevator includes an upper part area 1, a lower part area 2, a conveying track 3, a shot blasting machine 4, a shot cleaning room 5, a spraying room 6, a curing room 7 and a cooling station 8, The conveying track passes through the upper area 1, the shot blasting machine 4, the cleaning room 5, the spraying room 6, the curing room 7, the cooling station 8, and the lower area 2 to form a continuous operation production line. The shot blasting chamber 42 inwall in 4 is provided with the shot blasting device 41 that a plurality of openings are opposite, and this shot blasting chamber 42 is communicated with cleaning room 5, is provided with several cleaning guns in described cleaning room 5, and this cleaning room 5 The bottom is equipped with a recovery device inclined from the shot blasting chamber 5 to the shot blasting machine 4, so that the cleaned and fallen balls fall back into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com