Double-layer sealing non-standard cover furnace

A double-layer sealing and bell-type furnace technology, which is applied in the direction of bell-type furnaces, furnaces, heat treatment furnaces, etc., can solve problems such as high operating costs, high use costs, and failure to meet production capacity requirements, achieving economy and safety Improvement, production cost reduction, and the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

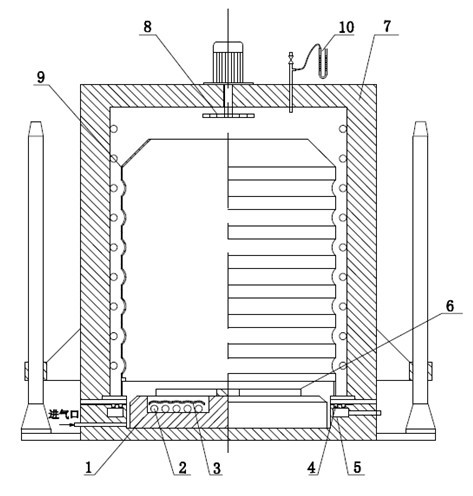

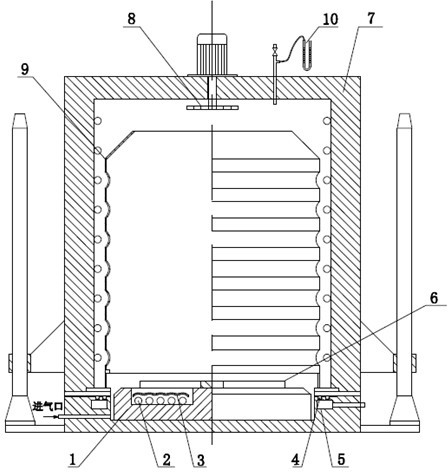

[0021] Embodiment: The structure of double-layer sealed non-standard bell-type furnace in this embodiment is as attached figure 1 As shown, it mainly includes a furnace base 1, a furnace bottom cross support frame 6 and a furnace cover 7. The main improvement is that there is a double-layer sealing ring 4 between the furnace base 1 and the furnace cover 7, and the inner layer of the double-layer sealing ring 4 is asbestos Packing, the outer layer is a silicone rubber ring.

[0022] The base heating element 2 is distributed on the furnace base 1 of this embodiment, and the heating element 2 is covered with a corrugated cover plate 3; an air inlet is provided on the side of the furnace base 1; there is a water cooling jacket 5 between the furnace base 1 and the furnace cover 7; The top of the furnace cover 7 is provided with a convection fan 8 and a U-shaped pressure gauge 10, and the furnace cover 7 has a corrugated inner cover air guide bucket 9.

[0023] Traditional bell fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com