Spicy chilli oil and preparation method thereof

A technology for spicy red oil and chili, which is applied in the directions of edible oil/fat, food science, application, etc., can solve the problems of insufficient chili oil flavor, unfavorable spice flavor, and low spice frying temperature, etc. Umami, rich aroma and palatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

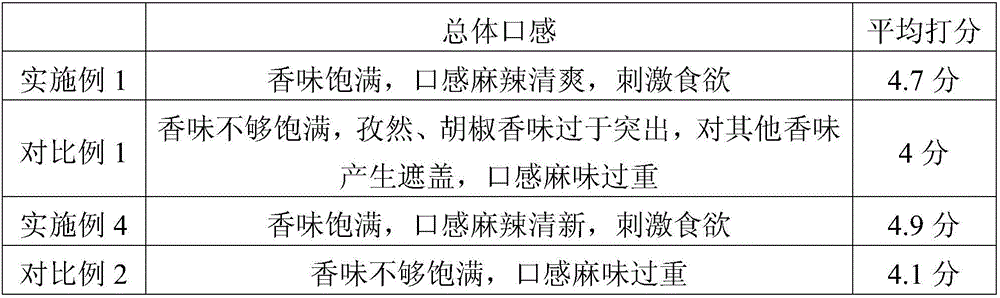

Examples

Embodiment 1

[0035]A spicy red oil prepared from the following raw materials in parts by weight: 80 parts of rapeseed oil, 6.5 parts of Chaotian pepper, 6 parts of red pepper, 1.3 parts of green onion, 1.1 part of ginger, 0.3 part of bay leaf, and 0.5 part of amomum , 0.7 parts star anise, 0.3 parts cinnamon, 0.4 parts grass fruit, 0.4 parts cumin, 0.3 parts cumin, 0.3 parts ginger, 0.2 parts pepper, 0.2 parts angelica, 0.2 parts tangerine peel, 0.2 parts cloves, 0.1 parts angelica, white 1 serving of sesame seeds.

[0036] The preparation method of above-mentioned spicy red oil comprises the following steps:

[0037] 1) Raw material pretreatment: cut the green onion into 4-6cm green onion segments, and set aside; slice the ginger to get ginger slices, set aside; mix Amomum seed, star anise, cinnamon, grass fruit, natural, cumin, sand ginger, sand Ren, angelica, pepper, clove, tangerine peel, and angelica dahurica were mixed in proportion and crushed to 40 mesh with a pulverizer to obtain...

Embodiment 2

[0043] A spicy red oil prepared from the following raw materials in parts by weight: 70 parts of rapeseed oil, 5 parts of Chaotian pepper, 5 parts of red pepper, 1 part of green onion, 1 part of ginger, 0.1 part of bay leaf, and 0.3 part of amomum , 0.5 parts of star anise, 0.1 parts of cinnamon, 0.3 parts of grass fruit, 0.3 parts of cumin, 0.1 part of cumin, 0.1 part of sand ginger, 0.1 part of pepper, 0.1 part of angelica, 0.1 part of tangerine peel, 0.1 part of clove, 0.05 part of angelica, white Sesame 0.5 part.

[0044] The preparation method of above-mentioned spicy red oil is with embodiment 1.

Embodiment 3

[0046] A spicy red oil prepared from the following raw materials in parts by weight: 90 parts of rapeseed oil, 10 parts of Chaotian pepper, 10 parts of red pepper, 2 parts of green onion, 2 parts of ginger, 0.5 part of bay leaf, and 0.8 part of amomum , 1 part star anise, 0.5 part cinnamon, 0.8 part grass fruit, 0.8 part cumin, 0.5 part cumin, 0.5 part ginger, 0.5 part pepper, 0.5 part angelica, 0.5 part tangerine peel, 0.5 part clove, 0.15 part angelica, white Sesame 1.5 parts.

[0047] The preparation method of above-mentioned spicy red oil is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com