Method for preparing malts with high malt aroma and beer thereof

A malt and aroma technology, which is used in the preparation of malt, biochemical equipment and methods, and beer brewing, etc., to achieve the effects of cool and transparent appearance, white and fine foam, and improving the content of malt aroma substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

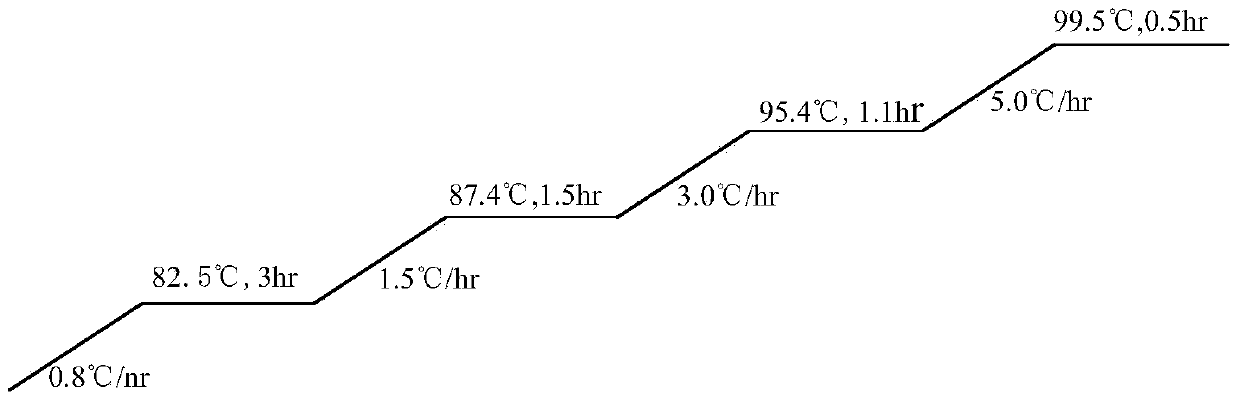

Embodiment 1

[0046] 1. High malt aroma malt-Aomai Gairdner

[0047] (1) Wheat selection: select high-quality barley as the raw material, the selected barley suitable for beer brewing has plump grains, the protein content of barley is 12.4%, and the germination rate of barley is 98%;

[0048] (2) Raw material pretreatment: After cleaning, grading, and storage, the moisture content of the barley is reduced to 13%, and the barley is stored dry at 15°C;

[0049] (3) Barley soaking: The barley soaking process is carried out by soaking water and cutting off the water. First, after the feeding is completed, overflow rinse or change the water quality. The barley is soaked at a low water temperature of 9°C for 6 hours, and continuous ventilation should be paid attention to during the soaking process. The ventilation temperature is 11.5 ℃, the ventilation pressure is 0.07Mpa, and the dissolved oxygen content in the soaking wheat water reaches 8mg / L. After wet immersion, dry immerse for 3 hours, and...

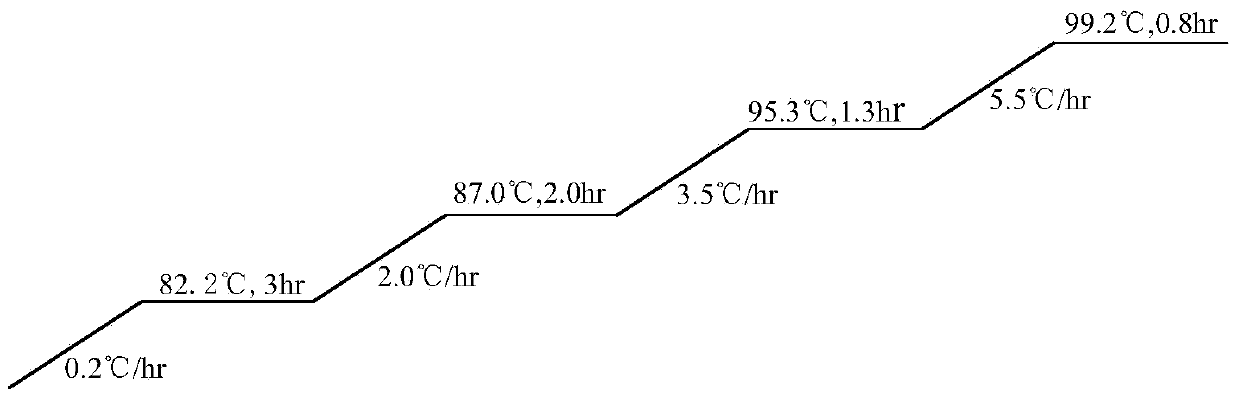

Embodiment 2

[0071] 1. High malt aroma malt - Jiamai Copeland

[0072] (1) Wheat selection: select high-quality barley as raw material, the selected barley suitable for beer brewing has full grains, the protein content of barley is 12.8%, and the germination rate of barley is 99%;

[0073] (2) Raw material pretreatment: After cleaning, grading, and storage, the moisture content of the barley is reduced to 15%, and the barley is stored dry at 15°C;

[0074] (3) Barley soaking: The soaking process is carried out by soaking in water and cutting off the water. First, after the feeding is completed, perform overflow rinsing or change the water quality. The barley is soaked at a water temperature of 9.5°C for 6 hours, and the soaking process pays attention to continuous ventilation, and the ventilation temperature is 11°C , the ventilation pressure is 0.06Mpa, and the dissolved oxygen content in the soaking wheat water reaches 7mg / L. After wet soaking, dry soaking for 3 hours, 2.00m per ton of ...

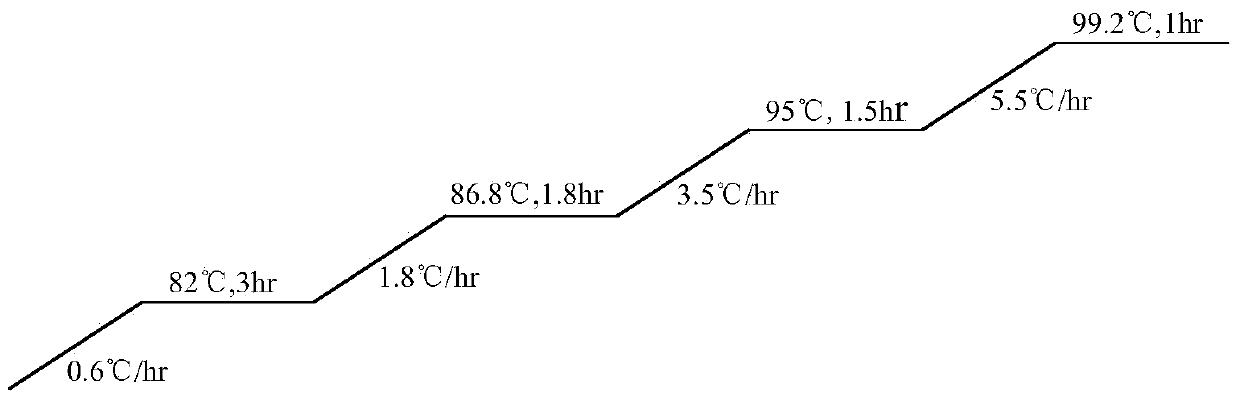

Embodiment 3

[0096] 1. High malt aroma malt - Guomai

[0097](1) Wheat selection: choose domestic high-quality Northwest barley as raw material, the selected barley suitable for beer brewing has full grains, the protein content of barley is 11.2%, and the germination rate of barley is 98%;

[0098] (2) Raw material pretreatment: After cleaning, grading, and storage, the moisture content of the barley is reduced to 15%, and the barley is stored dry at 15°C;

[0099] (3) Barley soaking: The soaking process is carried out by soaking in water and cutting off the water. First, after feeding, perform overflow rinsing or change the water quality. The barley is soaked in water at 10°C for 6 hours, and continuous ventilation should be paid attention to during the soaking process. The ventilation temperature is 12.5°C , the ventilation pressure is 0.07Mpa, and the dissolved oxygen content in the soaking wheat water reaches 7mg / L. After wet immersion, dry immerse for 3 hours, and use 2.20m per ton o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com