Gasoline processing method

A treatment method and gasoline technology, which are applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of rising pressure drop in the reactor, high sulfur content of gasoline for vehicles, affecting the long-term stable operation of the device, etc. Widen the source and delay the effect of top coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

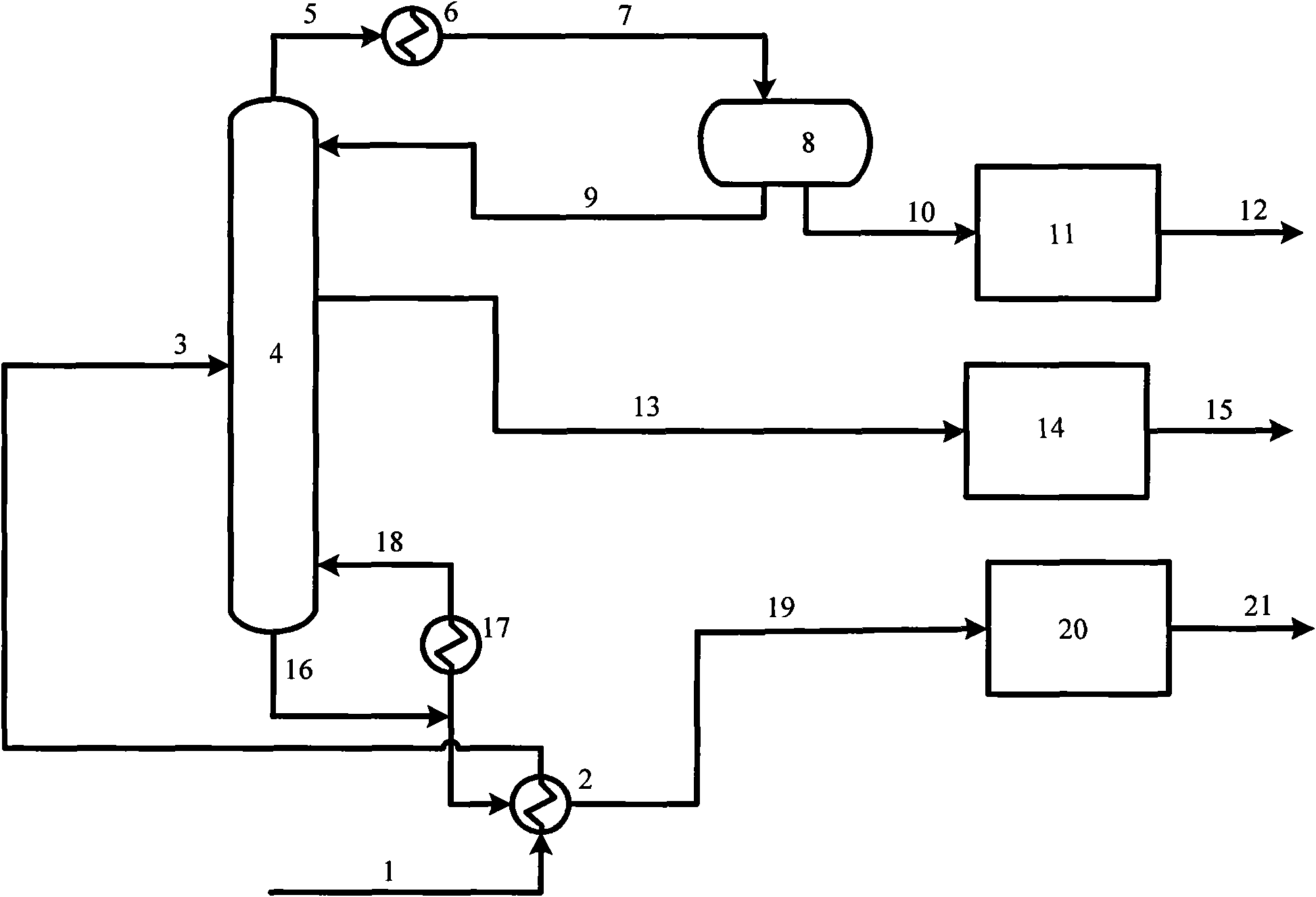

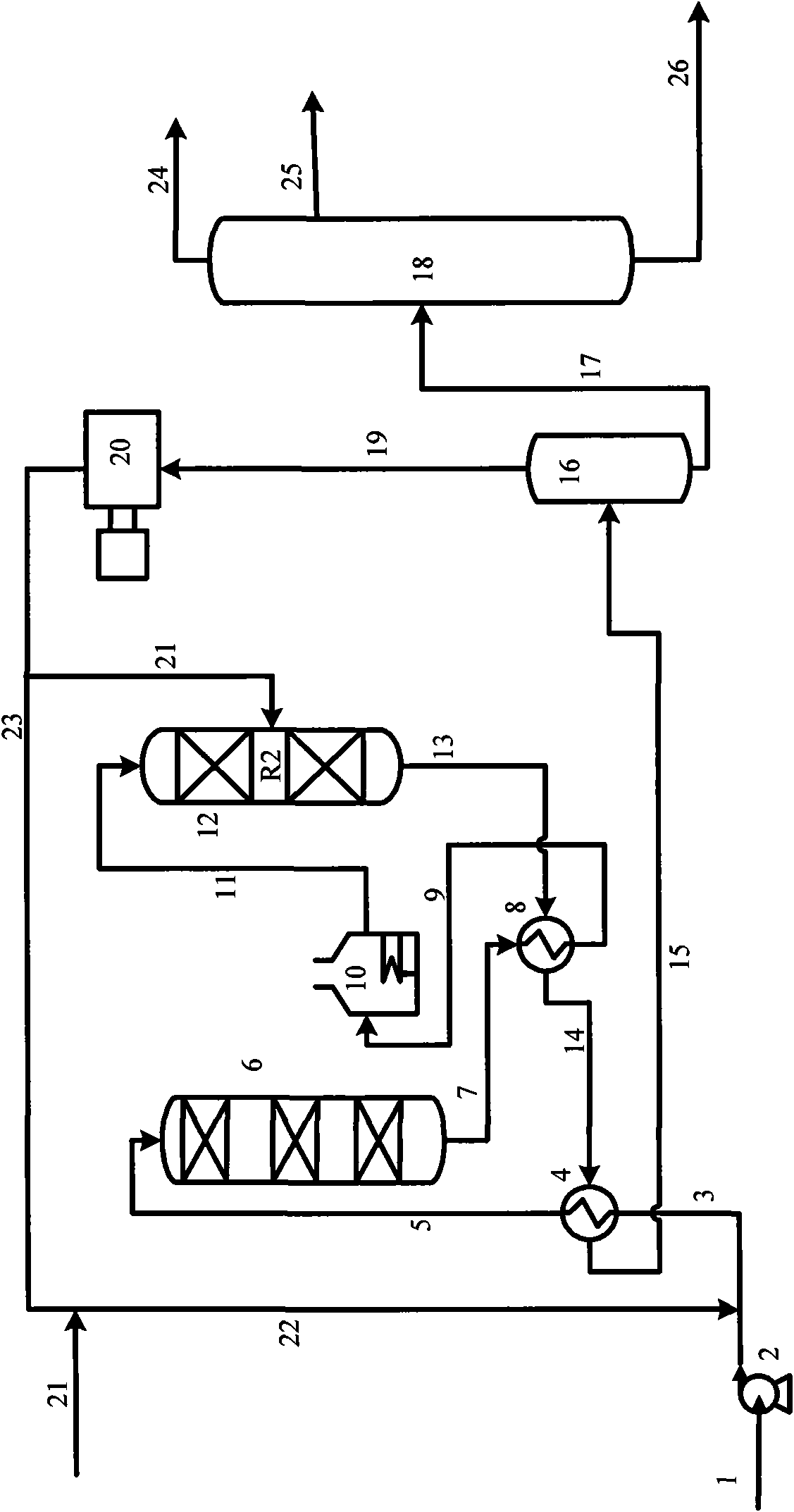

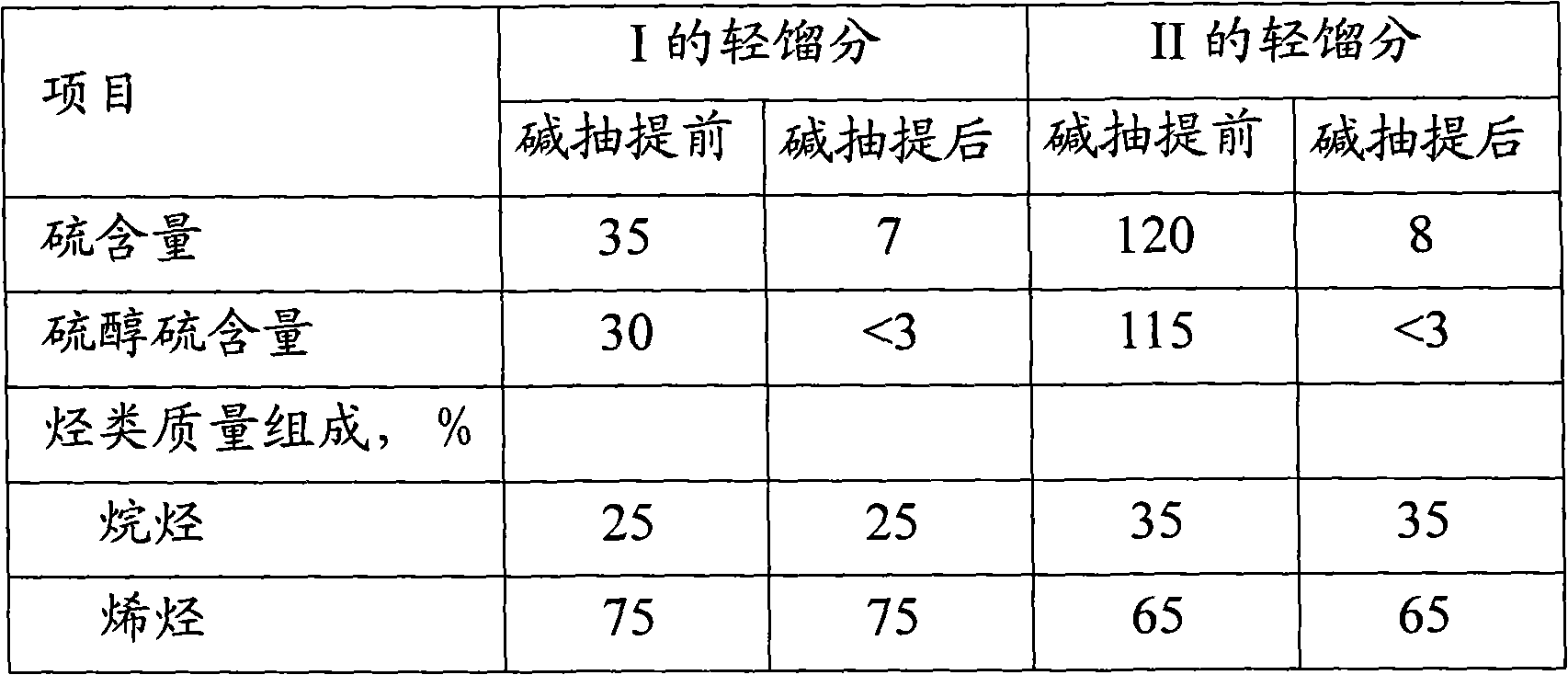

[0049] The raw materials used in the comparative example are the same, and their properties are shown in Table 1. First the whole fraction cuts the stock oil I into light fractions (C 5 and below), middle distillate (C 6 ~C 8 ) and heavy fractions (C 9 and above fractions), the proportion of light fractions is 6% by weight, carry out alkali extraction sweetening, the properties before and after treatment are shown in Table 3, as can be seen from Table 3, after alkali extraction, the sulfur content of light fractions is less than 10 μ g / g, The composition of the light fraction remains unchanged during the alkali extraction process, and the octane number is not lost, so it can be used as a high-quality gasoline blending component.

[0050] The proportion of the middle fraction is 68% by weight, and it and hydrogen enter the first reactor (first reverse) in the first hydrogenation unit to contact with the hydrodedienization catalyst, and remove dienes at 180 ° C, and the react...

Embodiment 2

[0053] A kind of catalytic cracking gasoline is used as raw material II, and its properties are shown in Table 1. First the whole fraction cuts the raw oil II into light fractions (C 5 and below), middle distillate (C 6 ~C 8 ) and heavy fractions (C 9 and above cuts), the light fraction ratio is 5% by weight, and alkali extraction is carried out to remove mercaptans. The composition of the light fraction remains unchanged during the alkali extraction process, and the octane number is not lost, so it can be used as a high-quality gasoline blending component.

[0054] The proportion of the middle fraction is 70% by weight, and it and hydrogen enter the first reactor (one reverse) in the first hydrogenation unit to contact with the hydrodedienization catalyst, and remove dienes at 180 ° C, and the reaction effluent in the first hydrogenation unit The second reactor (second reaction) is in contact with the hydrofinishing agent RS-1, and the hydrofining reaction is carried out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com