Production process of producing cleaning gasoline

A gasoline and clean technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of not meeting the requirements, achieve the effect of no loss of anti-knock index, and reduce the sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] This example prepares 2.0wt% NiO—0.50wt% ZnO—1.50wt% La 2 o 3 / Nano HZSM-5 desulfurization-reducing olefin catalyst.

[0041] Weigh 229.6g HZSM-5 (SiO 2 / Al 2 o 3 The molar ratio is 27, the grain size is 30nm~100nm) and 140.0gAl 2 o 3 , and grind and mix them evenly, add 150ml of dilute nitric acid solution and deionized water with a concentration of 5.6g / 100ml, and prepare a 1000ml slurry.

[0042] The above slurry was spray-dried, the air inlet temperature of the drying tower was 350°C, and the outlet air temperature was 150°C. The microspheres obtained by the cyclone separator were dried at 120° C. for 6 hours, and then calcined at 550° C. for 5 hours to prepare the nanometer HZSM-5 catalyst carrier intermediate. The obtained microspheres with a diameter of 40-100 microns accounted for 93 wt% of the total particles.

[0043] 100ml of the above-mentioned catalyst carrier intermediates were loaded into a vertical activation furnace, heated to 540° C. under an a...

example 2

[0047] This example prepares 4.0wt% MoO 3 —1.0wt%ZnO—3.0wt%La 2 o 3 / Ultrafine particle HBeta desulfurization-reducing olefin catalyst.

[0048] Weigh 239.6g HBeta(SiO 2 / Al 2 o 3 The molar ratio is 33, the grain size is 70nm~300nm), 140.0gAl 2 o 3 , and grind and mix them evenly, add 180ml of dilute nitric acid solution and deionized water with a concentration of 3.6g / 100ml, and prepare a 1000ml slurry.

[0049] The above slurry is spray-dried, the air inlet temperature of the drying tower is 320°C, and the outlet air temperature is 170°C. The microspheres obtained by the cyclone separator were dried at 110° C. for 8 hours, and then calcined at 570° C. for 3 hours. The obtained microspheres with a diameter of 40-100 microns accounted for 92 wt% of the total particles. Made into superfine particle HBeta desulfurization-reducing olefin catalyst carrier intermediate.

[0050] 120ml of the above-mentioned catalyst carrier intermediates were loaded into a vertical activa...

example 3

[0057] This example tests the catalytic performance of the NZ catalyst in Example 1.

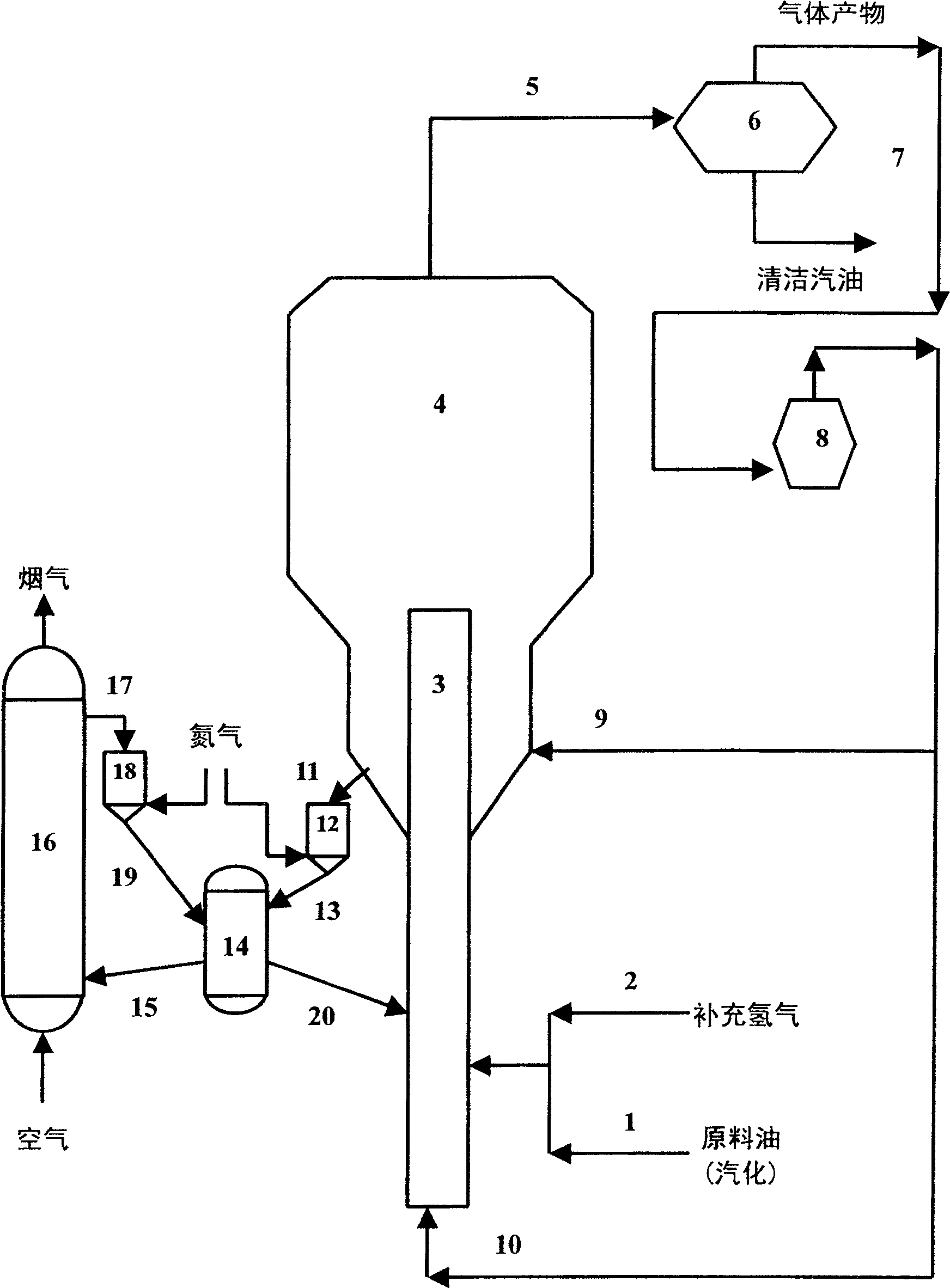

[0058] with A # FCC gasoline is used as raw material, using NZ catalyst, see the process figure 1 .

[0059] The operating conditions of the fluidized bed reactor are as follows: the reaction pressure is 3.0MPa, the reaction temperature is 400°C, and the feed volume space velocity is 2.5h -1 The volume ratio to hydrogen oil is 400:1.

[0060] The regeneration conditions are as follows: the regeneration pressure is 0.8MPa, the volume ratio of gas to agent is 700:1, the temperature is kept at 530°C for 5.0 hours, and the regeneration gas is air.

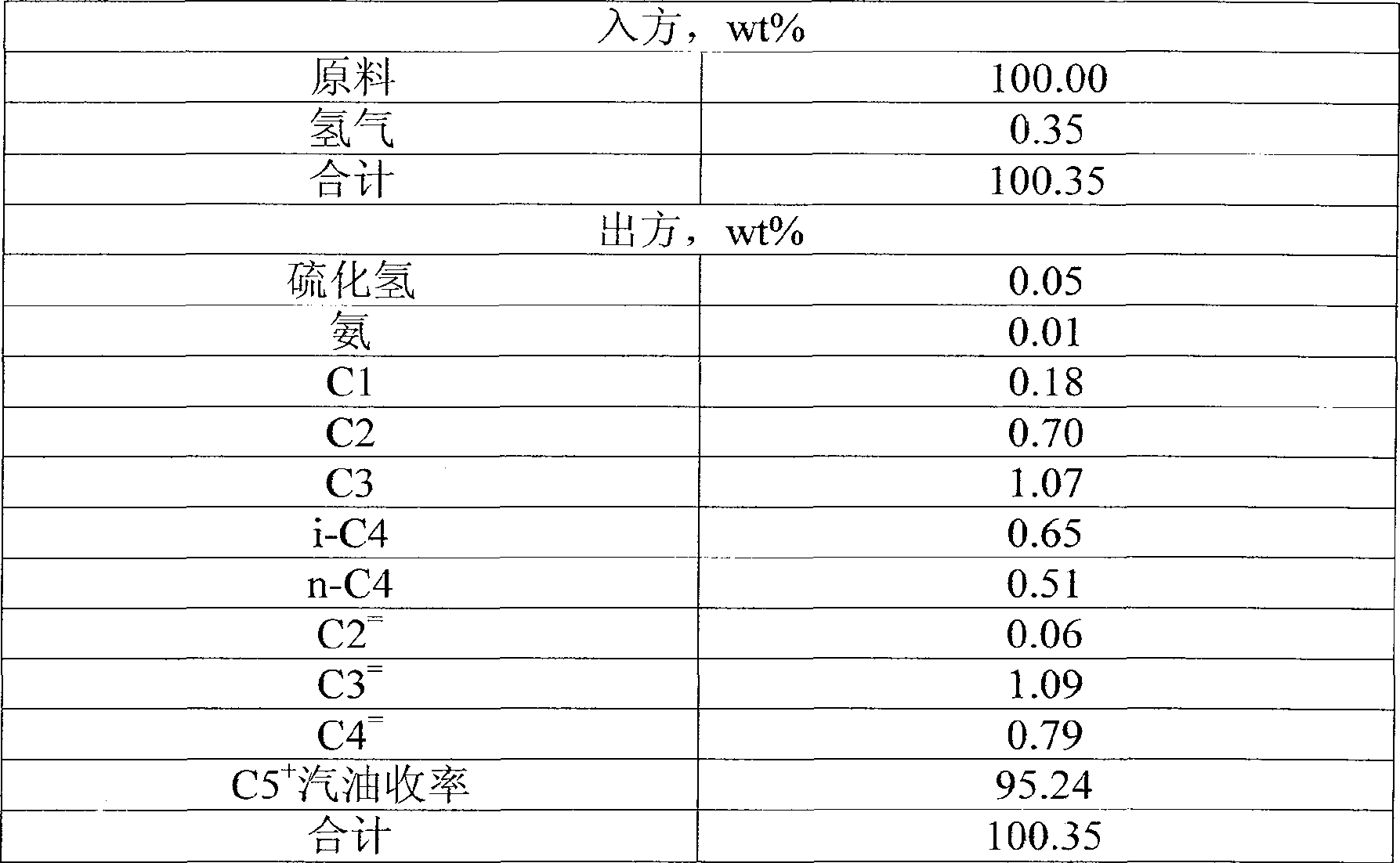

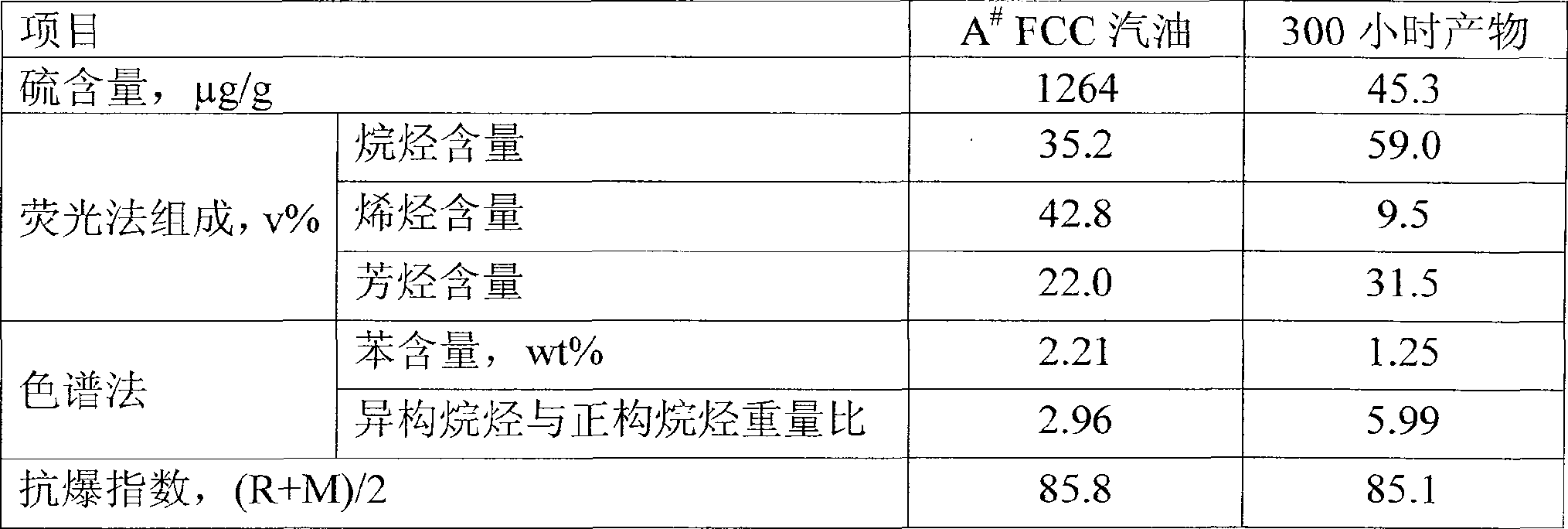

[0061] Run 300 hours of sampling and analysis. Table 2 presents the feedstock and product mass balance data, and Table 3 presents the analytical results for the liquid product.

[0062] Table 2 Example 3 raw material and product material balance

[0063]

[0064] The analysis result of table 3 example 3 liquid products

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com