Catalytic conversion method for lowering benzene content of benzene-rich gasoline component

A catalytic conversion method and benzene content technology, applied in the field of petroleum refining, can solve the problems of low reaction pressure, high reaction temperature, low mass ratio of benzene-rich gasoline components to methanol, etc., and achieve improved life, good stability, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

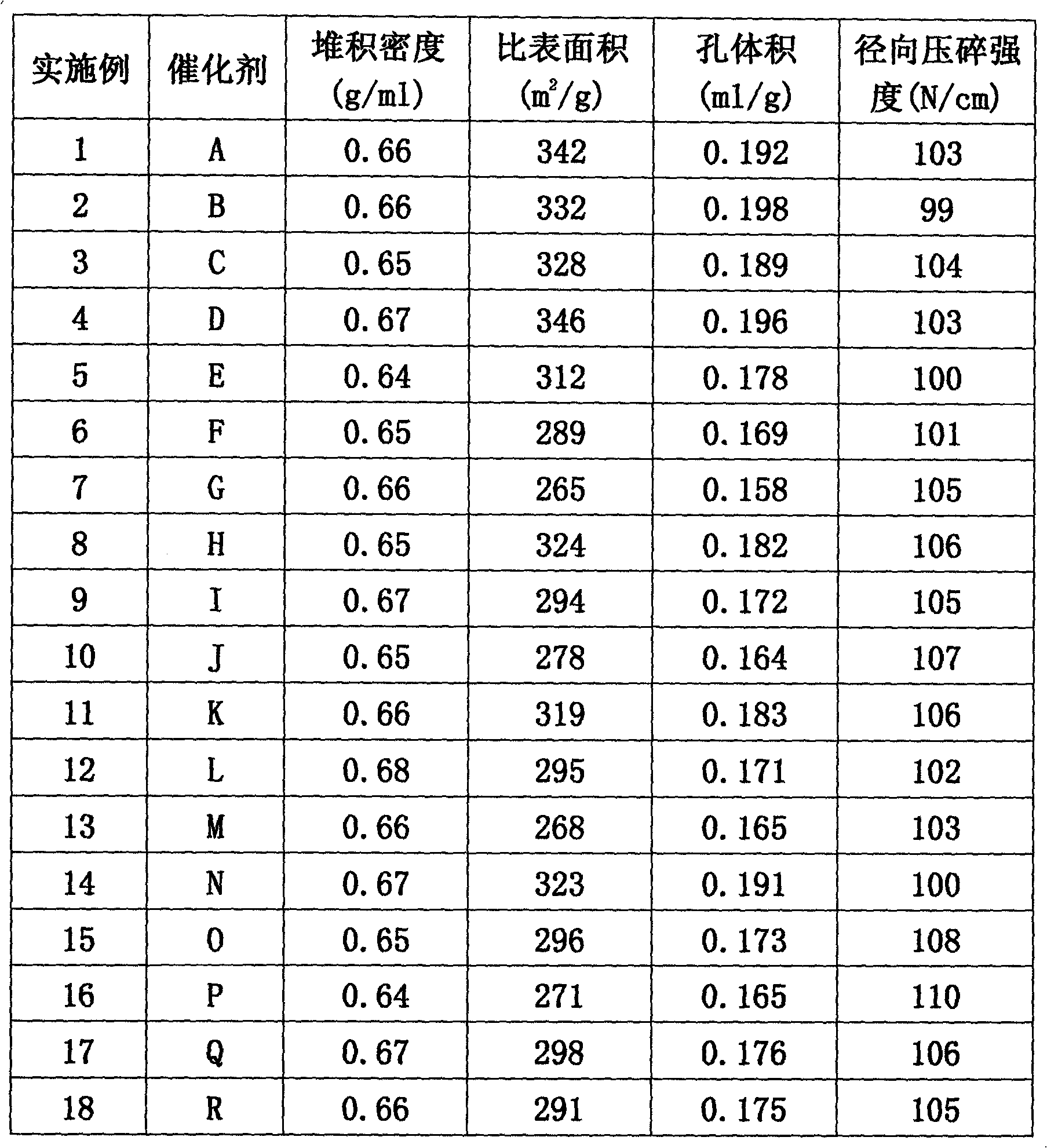

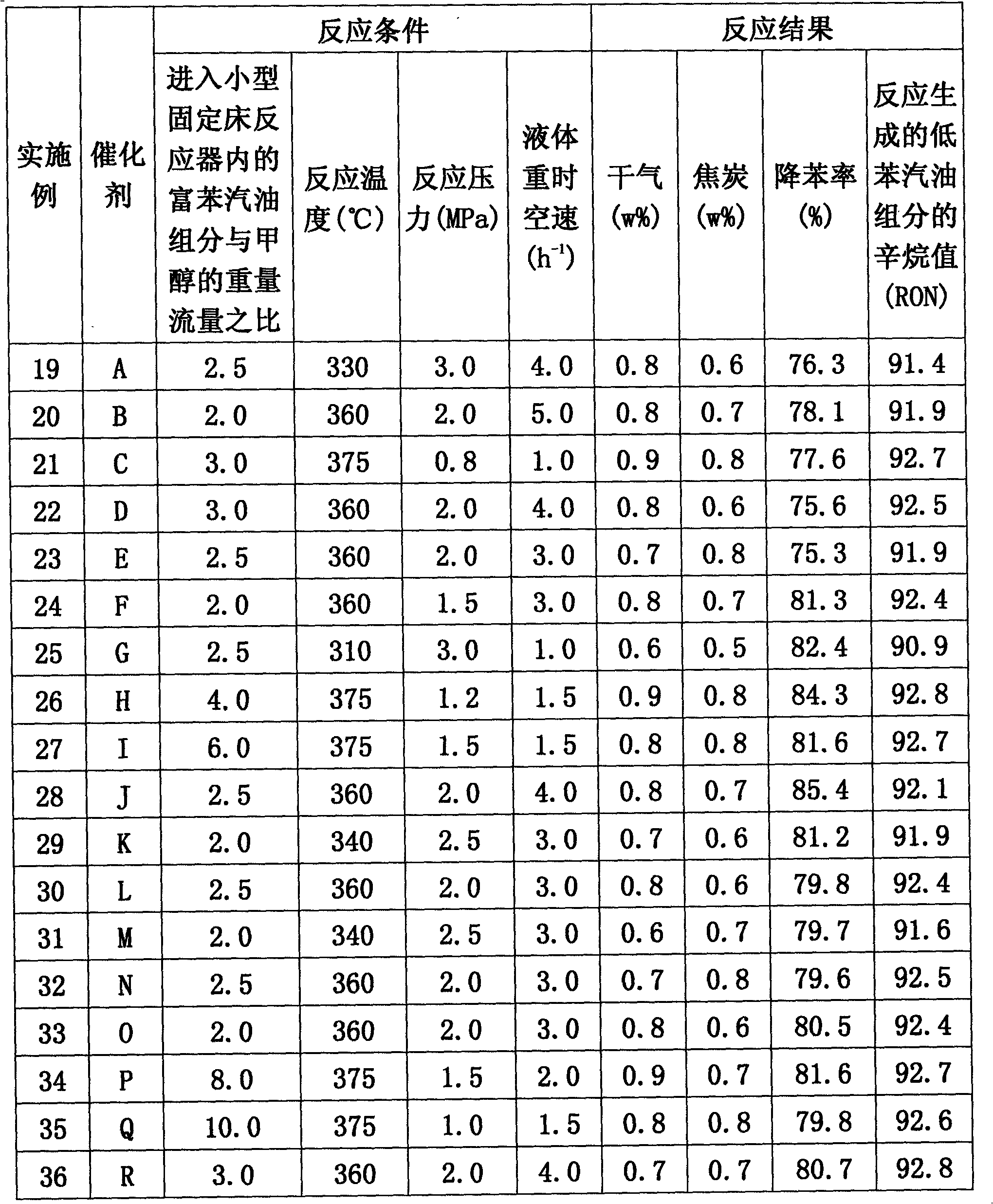

Examples

preparation example Construction

[0016] The preparation method of catalyst used in the present invention, for the catalyst that does not contain modifying element oxide, prepare according to the following steps: 1. earlier HZSM-5 type molecular sieve, HY type molecular sieve (do not add as not using), Hβ type molecular sieve ( Do not add if not in use), add water and concentrated nitric acid to the binder, and mix evenly to form a paste. ②Through shaping and processing, obtain strips or spherical objects. The bar is cylindrical, the length is generally 2 to 5mm, and the cross-sectional diameter is generally 1.5 to 2mm; the spherical thing is spherical, and the diameter is generally 1 to 3mm (the shape and size of the finished catalyst are the same as the described bar or spheres are the same). ③Dry the strips or spherical objects at a temperature of 90-120°C for 4-12 hours. ④ Baking at a temperature of 500-600°C for 1-6 hours. ⑤Aging treatment with water vapor at a temperature of 500-600 °C for 1-6 hours, ...

Embodiment 1

[0029] The HZSM-5 type molecular sieve that the dry weight is 275 grams, the silicon-aluminum ratio is 30 and the alumina that the dry weight is 225 grams, 160 grams of deionized water and 15 grams of concentrated nitric acid (concentration is 65w%, following examples are the same (1) after being uniformly mixed into a paste, extruded into strips on a molding machine. Thereafter, the strips were dried at a temperature of 120° C. for 4 hours, and then fired at a temperature of 600° C. for 3 hours. Then, aging treatment in the steam aging device for 4 hours; during aging treatment, the aging temperature is 550°C, and the weight hourly space velocity of water vapor is 1.0h -1 . After the aging treatment, the catalyst A is prepared; the content of the HZSM-5 molecular sieve is 55.0w%, and the rest is alumina.

Embodiment 2

[0031] Mix the HZSM-5 molecular sieve with a dry basis weight of 454 grams and a silicon-aluminum ratio of 500 with alumina with a dry basis weight of 46 grams, 160 grams of deionized water and 15 grams of concentrated nitric acid to form a paste, and then put it on the molding machine Squeeze into strips. Thereafter, the strips were dried at a temperature of 90° C. for 12 hours, and then fired at a temperature of 500° C. for 6 hours. Then, aging treatment in a steam aging device for 6 hours; during aging treatment, the aging temperature is 600 ° C, and the weight hourly space velocity of water vapor is 0.5h -1 . After the aging treatment, the catalyst B is prepared; the content of the HZSM-5 molecular sieve is 90.8w%, and the rest is alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com