Method for modifying gasoline

A low-quality gasoline and gasoline technology, applied in the petroleum industry, reforming naphtha, catalytic reforming of naphtha, etc., can solve the problems of gasoline difficulties and achieve the effect of increasing the octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

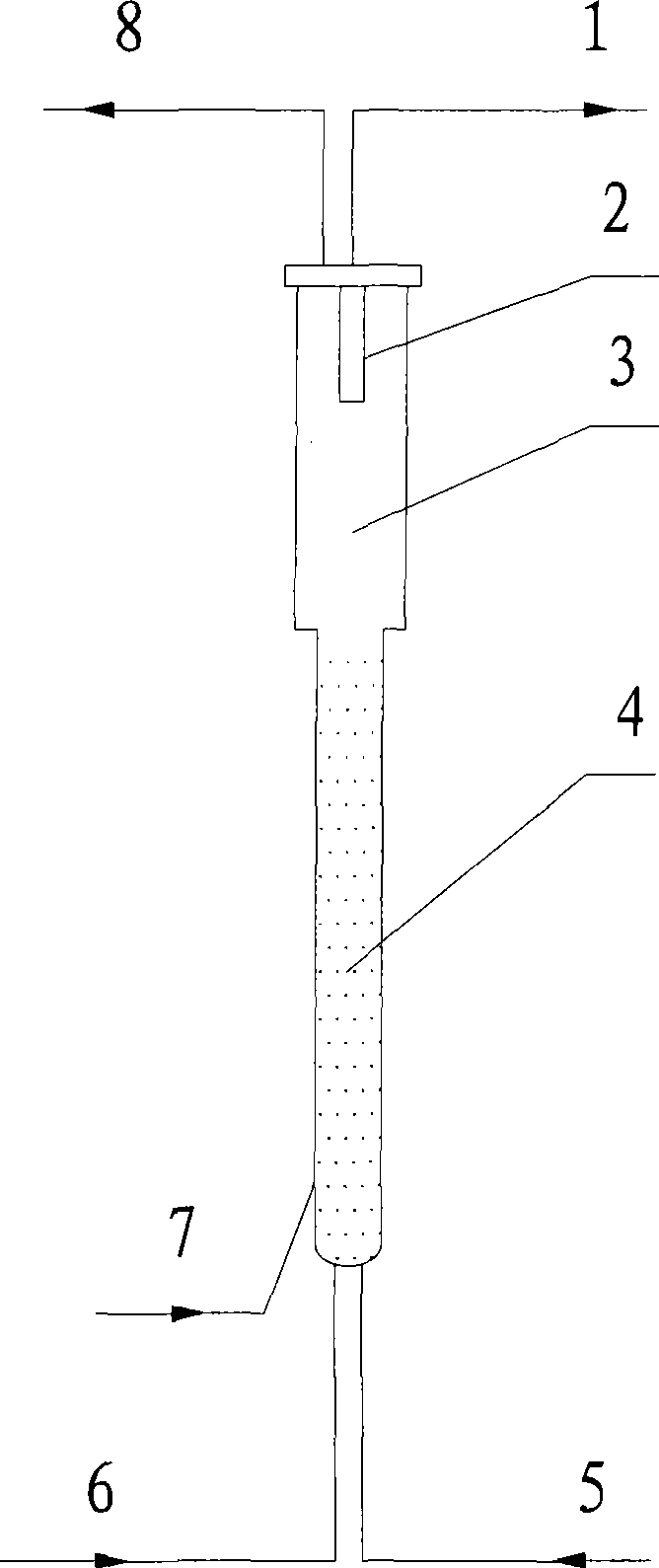

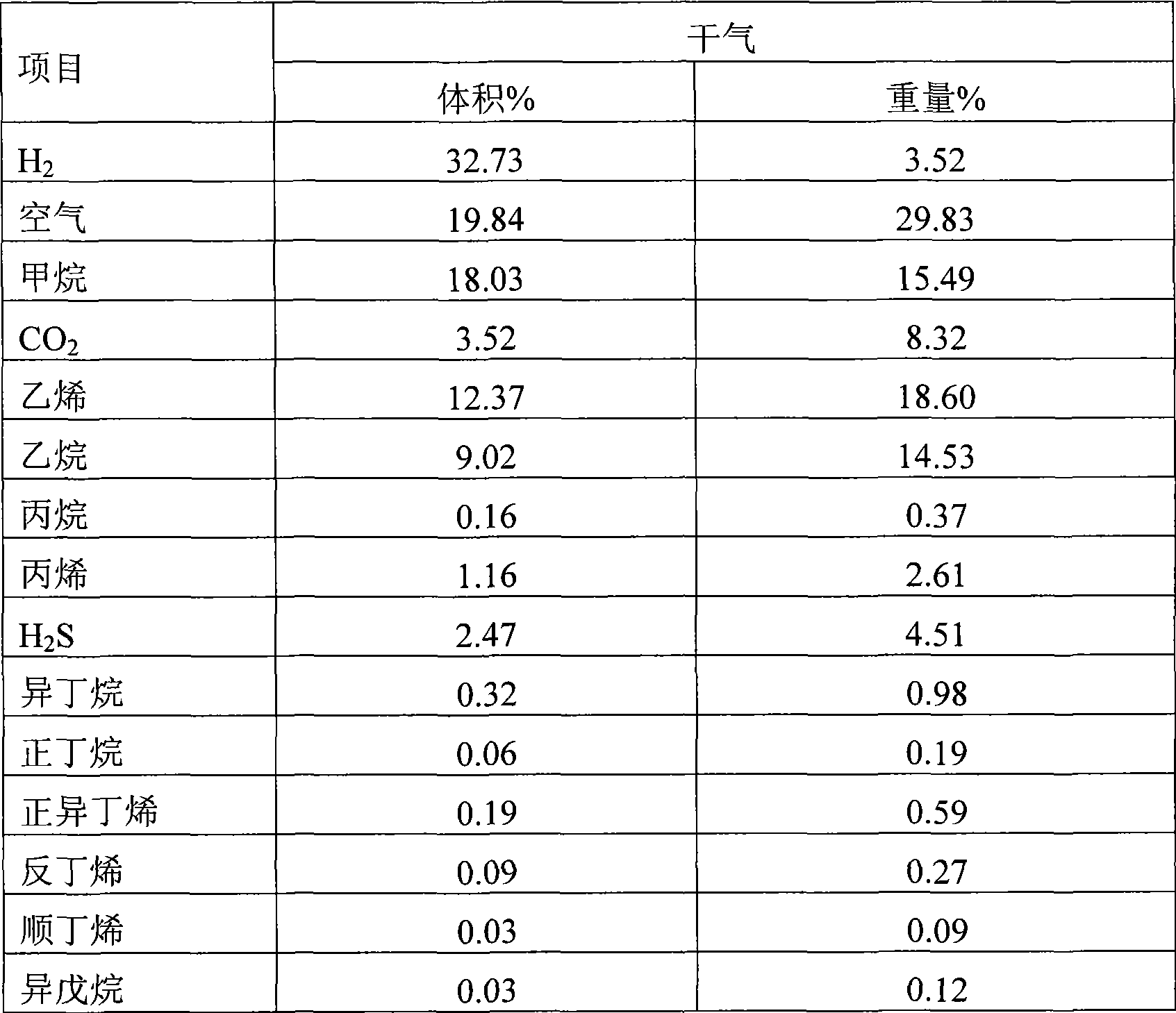

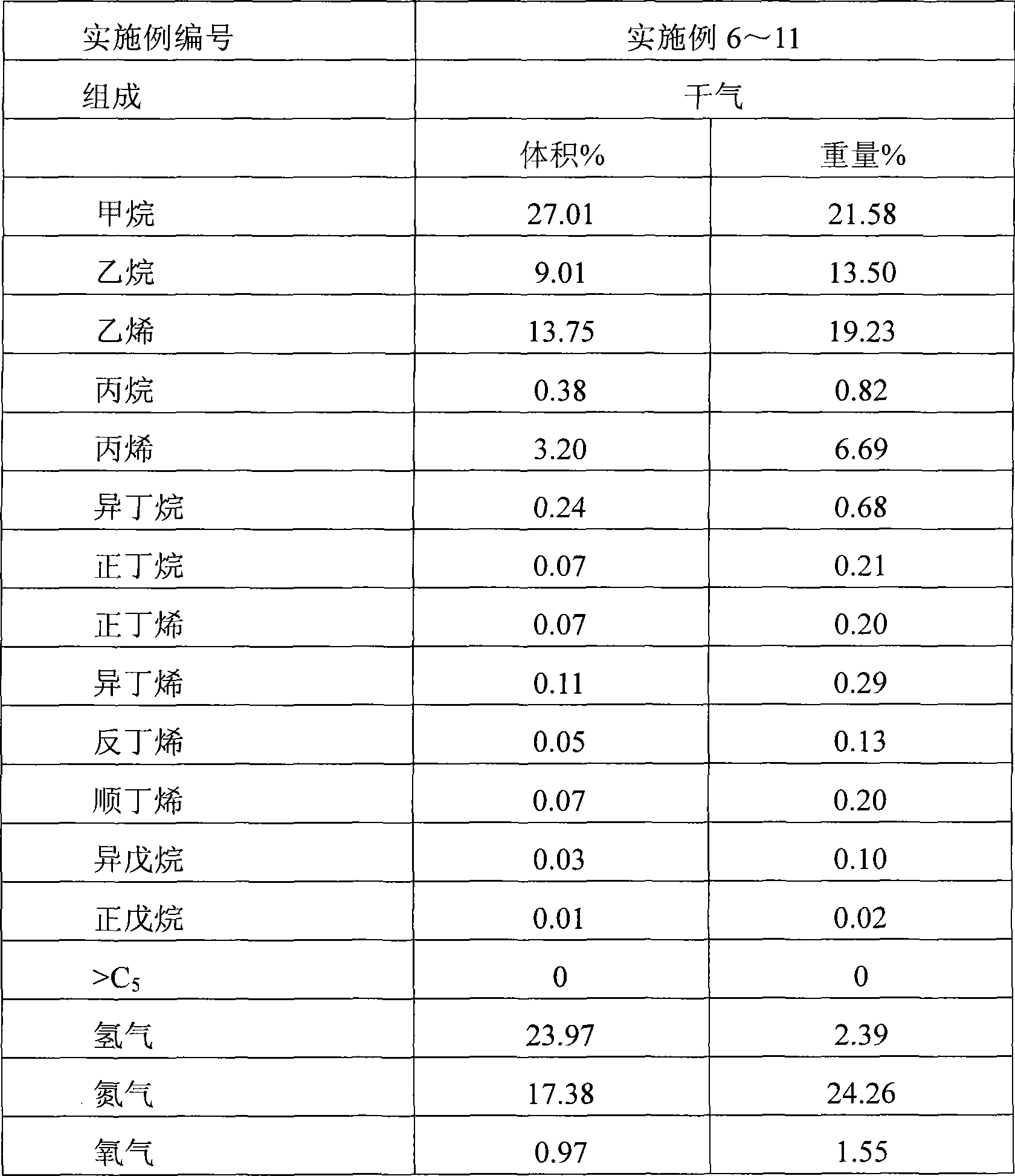

[0023] The test is carried out on the fluidized bed test device shown in the figure, the catalyst used in the test is a ZSM-5 molecular sieve catalyst, and the ZSM-5 molecular sieve content is 30% by weight. See Table 1 for feed properties of inferior gasoline, Table 2 for dry gas feed composition, Table 3 for reaction conditions, and Table 4 for properties of modified gasoline (gasoline with reduced benzene content in inferior gasoline).

Embodiment 2

[0025] According to Example 1, the difference is that the reaction temperature is 260° C., the reaction conditions are listed in Table 3, and the properties of the modified gasoline are listed in Table 4.

Embodiment 3

[0027] According to Example 1, the difference is that the reaction temperature is 280° C., the reaction conditions are listed in Table 3, and the properties of the modified gasoline are listed in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com