Method for producing olefin and low-benzene-content gasoline component from naphtha

A naphtha and naphtha content technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrocarbon cracking and hydrocarbon production, etc., can solve the problem of decreased yield of propylene and butadiene, high benzene content in reformed gasoline, and ineffective use of naphthenes and other problems to achieve the effect of increasing yield and reducing benzene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

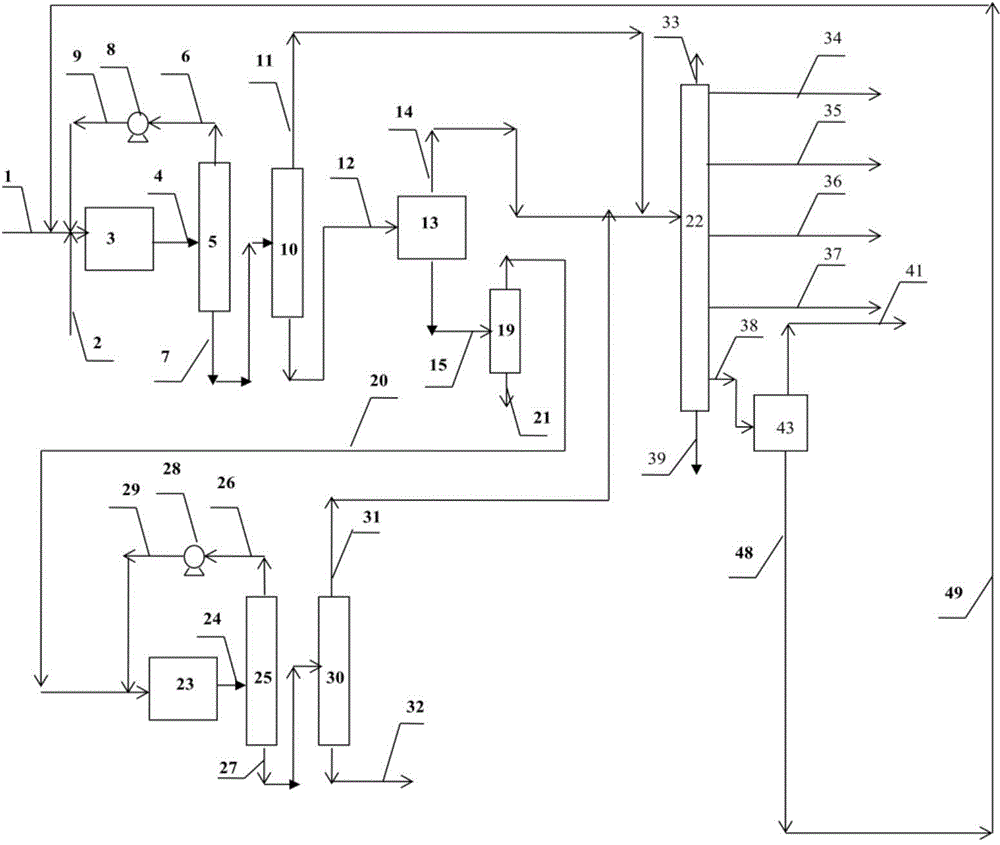

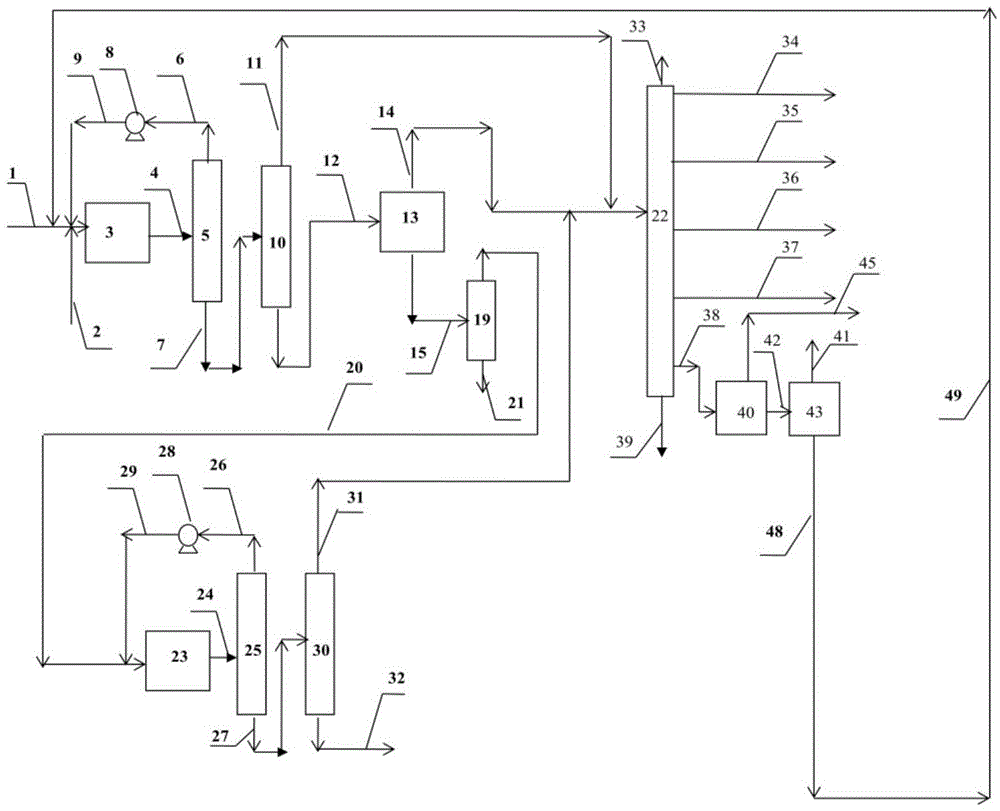

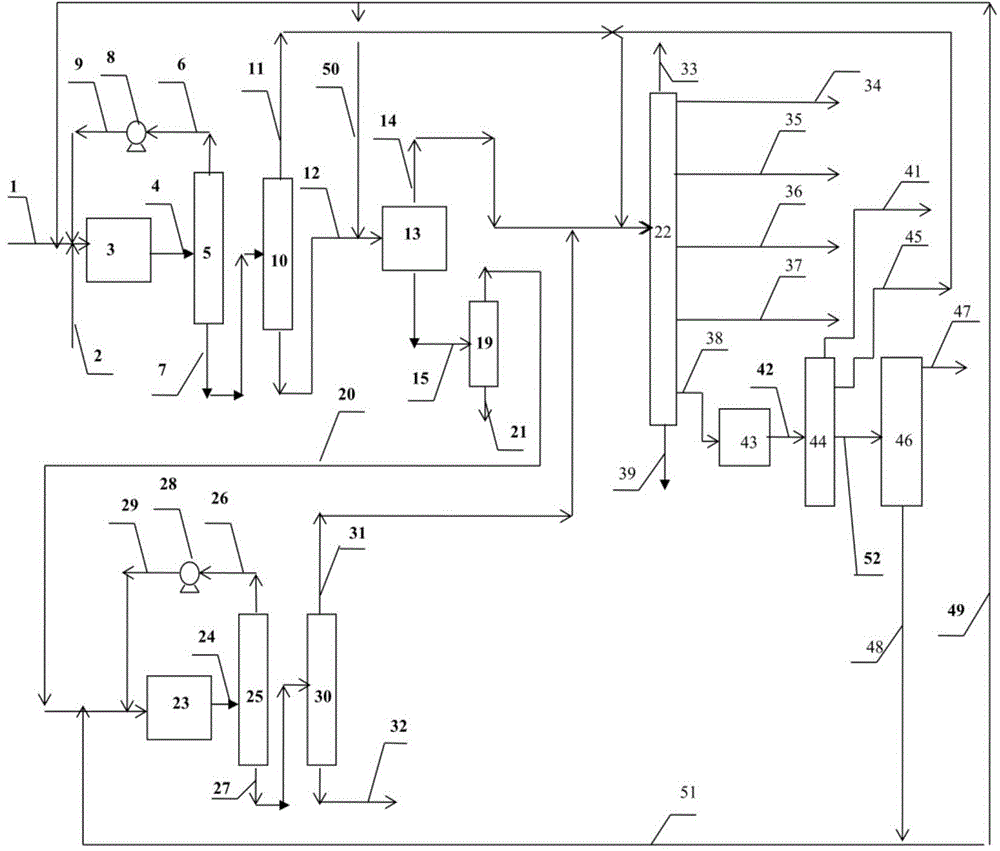

Method used

Image

Examples

example 1

[0076] In this example, naphtha is pre-hydrotreated.

[0077] In a 20 ml fixed-bed continuous flow reactor, fill 20 ml of pre-hydrofining catalyst A (brand RS-1, produced by Sinopec Catalyst Changling Branch), which contains 0.03% by mass of CoO, 2.0% by mass % NiO, 19.0 mass% WO 3 , 0.7% by mass of F and 78.27% by mass of Al 2 o 3 .

[0078] The naphtha with the composition and properties listed in Table 1 was heated at 290°C, the hydrogen partial pressure was 1.6MPa, the hydrogen / hydrocarbon volume ratio was 200:1, and the feed volume space velocity was 8.0h -1 Under the condition of passing through the above-mentioned reactor filled with catalyst A for pre-hydrofining, the reaction product enters the water cooler and is separated into two phases of gas and liquid, which are measured separately and analyzed for composition. The naphtha obtained after pre-hydrofining The composition and properties are shown in Table 2.

[0079] Table 1

[0080]

[0081] Table 2

[0...

example 2

[0085] Distilled naphtha is extracted according to the method of the present invention.

[0086] Using sulfolane as a solvent for extractive distillation, the naphtha after pre-hydrogenation listed in Table 2 is contacted with sulfolane in an extractive distillation tower at a flow rate of 100kg / h, the mass ratio of solvent / raw material is 6.0, and the extractive distillation tower The top pressure is 0.145MPa (absolute pressure), the reflux ratio is 0.25, the temperature at the top of the extractive distillation tower is 80°C, and the temperature at the bottom of the tower is 160°C. A solvent rich in aromatics and naphthenes is obtained from the bottom of the extractive distillation tower, and a solvent containing alkanes and C is obtained from the top of the tower. 6 Naphthenic raffinate, rich in aromatics and low in C 6 The solvent containing naphthenes is separated from the extraction solvent by distillation to obtain the extracted oil. The yield of extracted oil and raf...

example 3

[0088]Adopting N-formylmorpholine as the extractive distillation solvent, the naphtha listed in Table 2 is contacted with N-formylmorpholine in the extractive distillation tower with a flow rate of 100kg / h, the solvent / raw material mass ratio is 7.0, and the extractive distillation The pressure at the top of the tower is 0.145MPa (absolute pressure), the reflux ratio is 0.25, the temperature at the top of the extractive distillation tower is 76°C, and the temperature at the bottom of the tower is 170°C. A solvent rich in aromatics and naphthenes is obtained from the bottom of the extractive distillation tower, and a solvent containing alkanes and C is obtained from the top of the tower. 6 Naphthenic raffinate. Rich in aromatics and low in C 6 The solvent containing naphthenes is separated from the extraction solvent by distillation to obtain the extracted oil. The yield of extracted oil and raffinate (relative to naphtha), group composition and distribution ratio of various ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com