Catalytic conversion method for reducing benzene content in gasoline

A catalytic conversion method and a technology of benzene content, which are applied in the field of catalytic conversion to reduce the benzene content of gasoline, can solve the problems of increased equipment investment, reduced gasoline yield, complicated separation process, etc., and achieve increased gasoline yield, improved gasoline quality, gasoline The effect of octane number improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

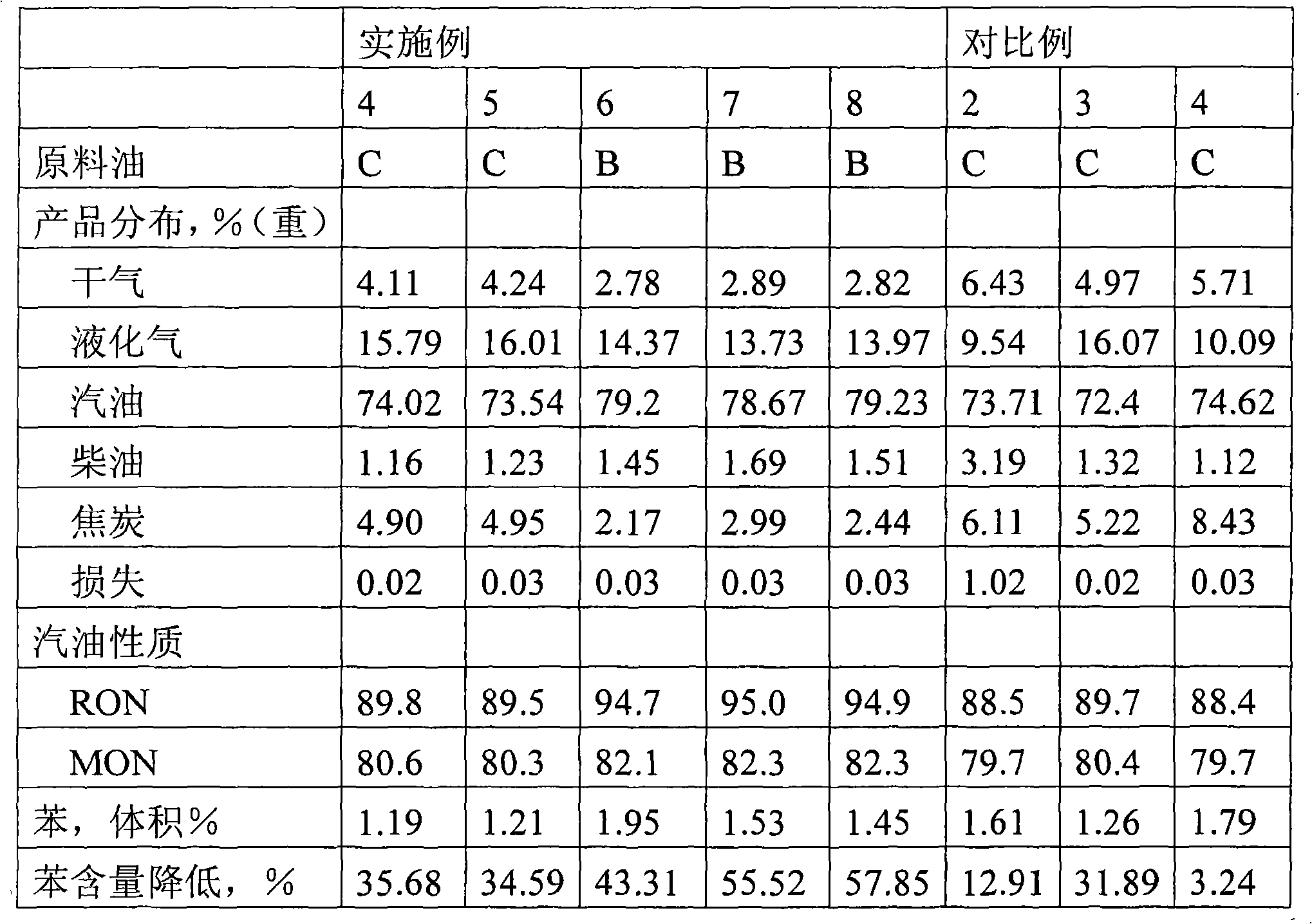

[0037] This example illustrates the use of the method provided by the present invention.

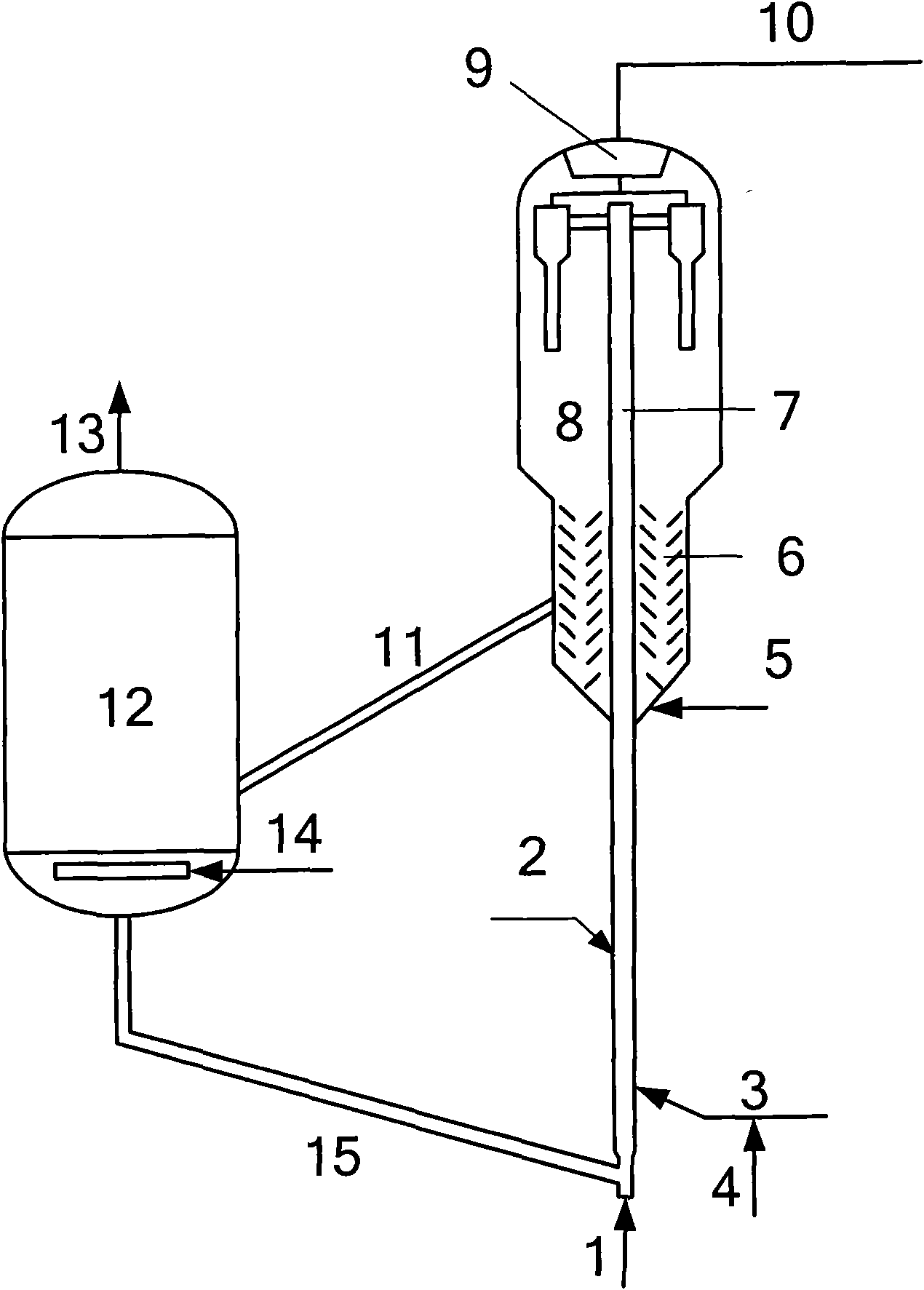

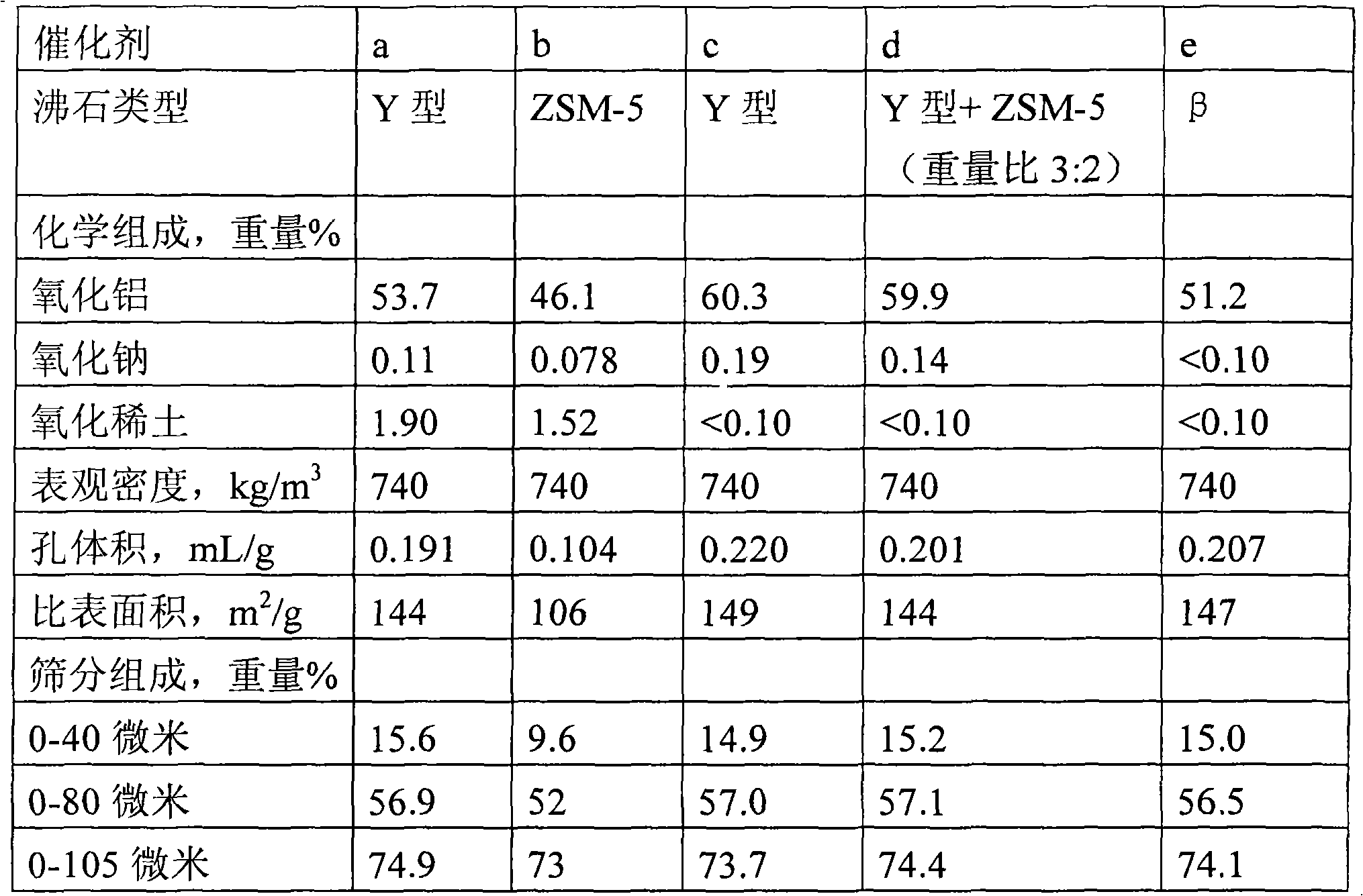

[0038] use figure 1 In the shown process, the benzene-containing gasoline A listed in Table 1 is used as the reaction raw material, methanol (Beijing Chemical Plant, purity ≥ 99.5%) is used as the alkylating agent, and Y-type molecular sieves (catalyst a in Table 2 for properties) are used as the reaction material. Catalyst, the catalytic conversion reaction of gasoline and methanol is carried out in a small fluidized bed reactor to produce low-benzene gasoline.

[0039] The mixture of benzene-containing gasoline A and methanol and preheated high-temperature steam are mixed into the fluidized bed reactor. At a reaction temperature of 400°C, the weight ratio of catalyst to total liquid feed is 15, methanol and benzene-containing gasoline The weight ratio is 0.25:1, and the space velocity is 10h -1 , under the condition that the water injection amount (accounting for the total liquid fee...

Embodiment 2

[0042] use figure 1 Shown technique, with the listed benzene-containing gasoline B of table 1 as reaction raw material, methyl alcohol (Beijing Chemical Plant, purity ≥ 99.5%) is used as alkylating agent, uses ZSM-5 type molecular sieve (property sees catalyst b in table 2 ) as a catalyst, the catalytic conversion reaction of gasoline and methanol is carried out in a small fluidized bed reactor to produce low-benzene gasoline.

[0043] The mixture of benzene-containing gasoline B and methanol and preheated high-temperature steam are mixed into the fluidized bed reactor. At a reaction temperature of 300°C, the weight ratio of the catalyst to the total liquid feed is 6, methanol and benzene-containing gasoline The weight ratio is 0.20:1, and the weight hourly space velocity of the total liquid feed is 8h -1 , under the condition of 10% by weight of water injection (accounting for the total liquid feed amount), contact with the catalyst to carry out catalytic conversion to prepa...

Embodiment 3

[0046] use figure 1 In the shown technique, the gasoline C containing benzene listed in Table 1 is used as the reaction raw material, methanol (Beijing Chemical Plant, purity ≥ 99.5%) is used as the alkylating agent, and ZSM-5 type molecular sieves are used (see catalyst b in Table 2 for properties). ) as a catalyst, the catalytic conversion reaction of gasoline and methanol is carried out in a small fluidized bed reactor to produce low-benzene gasoline.

[0047] The mixture of benzene-containing gasoline C and methanol and preheated high-temperature steam are mixed into the fluidized bed reactor. At a reaction temperature of 500°C, the weight ratio of catalyst to total liquid feed is 6, methanol and benzene-containing gasoline The weight ratio is 0.125:1, and the weight hourly space velocity of the total liquid feed is 8h -1 , under the condition of 10% water injection (accounting for the total liquid feed), contact with the catalyst to carry out catalytic conversion to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com