Preparation method of edible oil leaching agent

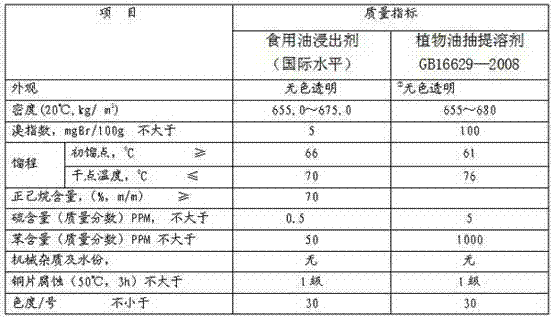

A manufacturing method and technology of extracting agent, applied in the direction of edible oil/fat, application, food science, etc., can solve the problems of not meeting the international level requirements of the food industry, and achieve the effect of human body safety and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention carries out according to the following procedures:

[0019] 1. Aromatic raffinate oil from petroleum refining (its main components are C6-C8 alkanes, a certain amount of naphthenes and a small amount of aromatics) enters the fiber membrane contactor, and the sulfolane carried by the aromatics raffinate is removed by water washing. For sulfur removal, the operating conditions are that the ratio of oil to water is 10:2~4, the operating temperature is 40°C, the operating pressure is 0.1~1.0MPa, and the pressure drop of the fiber membrane contactor is less than 0.07 MPa. The oil phase coming out of the fiber membrane contactor passes through molecular sieve facilities to remove water, so as to achieve the purpose of sulfur removal, and its water content is controlled to be less than 100PPM.

[0020] 2. Put the desulfurized and dehydrated raw materials into the hydrogenation reactor, the reaction pressure is 1.0~2.5MPa, the reaction temperature is 150°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com