Aromatization catalyst and application thereof in highly selective preparation of p-xylene

A catalyst and aromatization technology, applied in physical/chemical process catalysts, isomerization to hydrocarbons, molecular sieve catalysts, etc., can solve the problems of reduction, lowering selectivity, crystal destruction, etc., to improve operation efficiency and suppress side reactions , improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of catalyst (E-1) of the present invention is as follows:

[0035] (1) Preparation of lanthanum-containing molecular sieves

[0036] Use lanthanum nitrate and water to prepare a solution with a concentration of lanthanum oxide of 0.2 wt%, and add the calculated amount of solution to HZSM-5 (the molar ratio of silicon to aluminum is 80, and the specific surface area is 328m 2 / g, pore volume 0.18ml / g), the mixture was dried for 8 hours, then in an air atmosphere at 550 ° C, roasted for 6 hours to obtain a ZSM-5 molecular sieve with a lanthanum oxide content of 8 wt%, which is referred to as ZSM-5A here.

[0037] (2) Preparation of carrier

[0038] 400 grams of ZSM-5A, 200 grams of Sb 2 o 3 (analytically pure, produced by Shanghai Reagent No. 4 Factory), 400 grams (dry basis weight, the same below) of SB alumina powder (produced in Germany, the brand name is SB) and 24 grams of scallop powder are mixed evenly, then add 720ml of water, 36ml of Co...

Embodiment 2

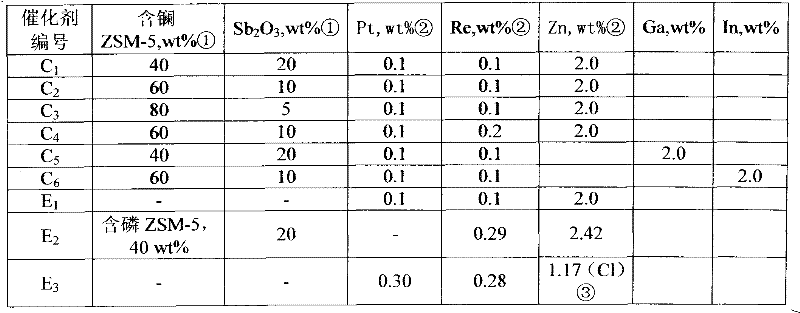

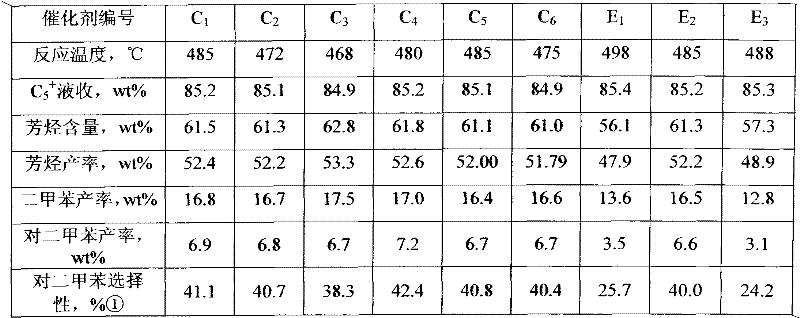

[0042] Catalyst preparation method is the same as embodiment 1, and difference is that the content of molecular sieve in catalyst carrier is 60wt%, Sb 2 o 3 The content of the catalyst is 10wt%; the content of platinum, rhenium and zinc in the catalyst is different, and the catalyst number is C 2 , its composition is shown in Table 1, and the evaluation results are shown in Table 2.

Embodiment 3

[0044] Catalyst preparation method is the same as embodiment 1, and difference is that the content of molecular sieve in catalyst carrier is 80wt%, Sb 2 o 3 The content of the catalyst is 5wt%; the content of platinum, rhenium and zinc in the catalyst is different, and the catalyst number is C 3 , its composition is shown in Table 1, and the evaluation results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com