Rat glue having attraction effects, preparation method of the rat glue and rat glue plate coated with the rat glue

A sticky mouse glue and coating technology, applied in the field of sticky mouse glue, can solve the problems of sticky mouse board sticky catch rate drop, sticky catch performance drop, glue surface pollution, etc., to achieve high utilization rate of resources, stable quality, trapping high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the mouse glue with attracting effect of the present invention comprises the following steps:

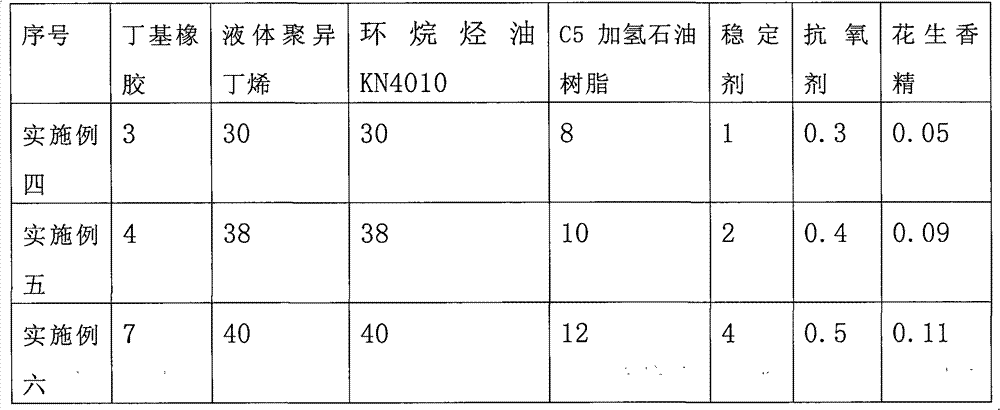

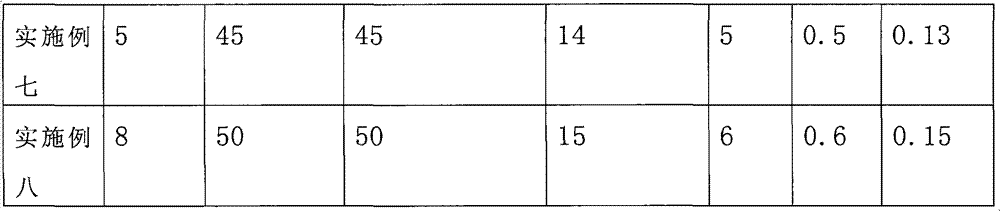

[0027] (1) Configure the following materials according to the weight ratio: 3-8 parts of butyl rubber, 30-50 parts of liquid polyisobutylene, 30-50 parts of naphthenic oil, 8-15 parts of C5 petroleum resin, 1-6 parts Part of polyethylene, 0.3-0.6 part of antioxidant, 0.05-1.5 part of peanut essence;

[0028] (2) Put 3-8 parts of butyl rubber and 15%-25% liquid polyisobutylene of the added butyl rubber mass into a pressurized rubber mixer, knead under a pressure of 0.2-0.6Mpa, and knead Refining for 0.4-1 hour;

[0029] (3) Add the kneaded butyl rubber and liquid polyisobutylene mixture, all the remaining liquid polyisobutylene in the batching, 0.3-0.6 parts of antioxidant, and 1-6 parts of polyethylene into the rubber-making kettle. Stirring for 4-10 hours under normal pressure and temperature of 140°C-180°C;

[0030] (4) After butyl rubber and li...

Embodiment 1

[0034] Raw material ratio: butyl rubber: 6 parts; liquid polyisobutylene: 41.9 parts; naphthene oil: 39.1 parts; C5 petroleum resin: 8.5 parts; polyethylene: 3 parts; Antioxidant AT10: 0.4 parts.

[0035] Preparation:

[0036] (1) Prepare raw materials according to the above ratio;

[0037] (2) 6 parts of butyl rubber and 0.9 part of liquid polyisobutylene are put into a pressurized rubber mixer, mixed under a pressure of 0.4Mpa, and mixed for 0.4 hours;

[0038] (3) Add the kneaded rubber and liquid polyisobutylene mixture, 41 parts of liquid polyisobutylene, 3 parts of polyethylene, and 0.4 parts of AT10 into the rubber making kettle, and stir at normal pressure and 160°C for 5 Hour;

[0039] (4) After stirring for 5 hours, add 8.5 parts of C5 petroleum resin and 39.1 parts of naphthenic oil, continue stirring for 1.5 hours under normal pressure and temperature of 140°C, and add 0.1 part of peanut essence 15 minutes before discharging.

Embodiment 2

[0041]Raw materials: butyl rubber: 8 parts; liquid polyisobutylene: 50 parts; naphthenic oil: 50 parts; C5 petroleum resin: 15 parts; polyethylene: 6 parts; Agent AT10: 0.6 parts.

[0042] Preparation:

[0043] (1) Prepare raw materials according to the above ratio;

[0044] (2) Put 8 parts of butyl rubber and 2 parts of liquid polyisobutylene into a pressurized rubber mixer, knead at a pressure of 0.6 MPa, and knead for 1 hour.

[0045] (3) Add the mixed rubber and liquid polyisobutylene mixture, 48 parts of liquid polyisobutylene, 6 parts of polyethylene, and 0.6 parts of AT10 into the rubber making kettle, and stir for 10 minutes at normal pressure and 180 ° C. Hour.

[0046] (4) After stirring for 10 hours, add 15 parts of C5 hydrogenated petroleum resin, 50 parts of naphthenic oil KN4010, continue stirring for 1.5 hours under normal pressure and temperature of 180 ° C, and add 1.5 parts of peanuts 15 minutes before discharging essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com