Method for synthesizing aviation kerosene cycloparaffin and aroma components by utilization of wood chips

A technology for aviation kerosene and naphthenic hydrocarbons, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils. , the effect of low vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

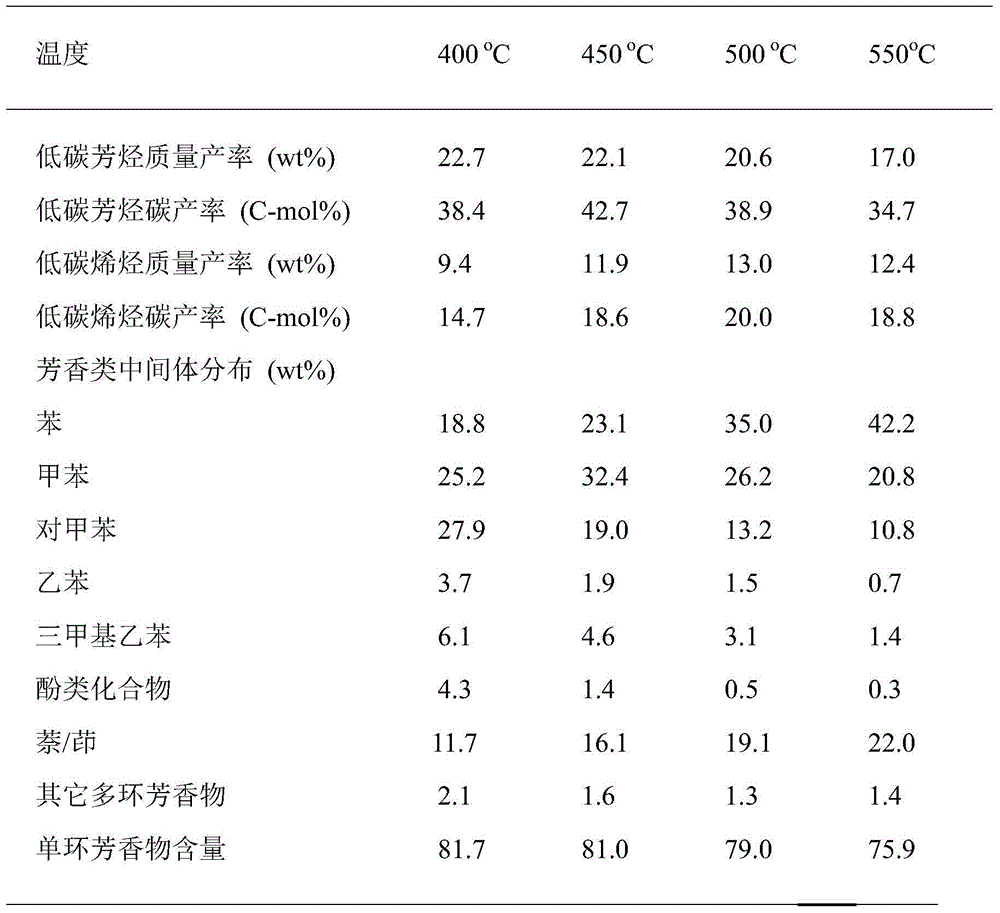

[0027] The effect of temperature on catalytic cracking and deoxygenation of wood chips into low-carbon aromatics and low-carbon olefins:

[0028] The purpose of this example is to illustrate the effect of converting lignocellulosic biomass (wood chips) into low-carbon aromatics and low-carbon olefins by catalytic cracking and deoxygenation of wood chips and the effect of temperature, but does not limit this method.

[0029] In this example, the sawdust raw material was purchased from Hefei Lanxu Biotechnology Co., Ltd. The main elements in the sawdust raw material are carbon, hydrogen and oxygen (the element ratio is C:H:O=46.20:6.02:47.30). The catalyst used for wood chip depolymerization and deoxidation is 3.1wt% NiO / 14.5wt% MgO / 82.4wt% Al-MCM-41 catalyst. The preparation steps of the catalyst are as follows: weigh 2.4g of commercially available nickel nitrate hexahydrate and 18.6g of magnesium nitrate hexahydrate, add 100mL of deionized water, and configure a nitrate mixed...

Embodiment 2

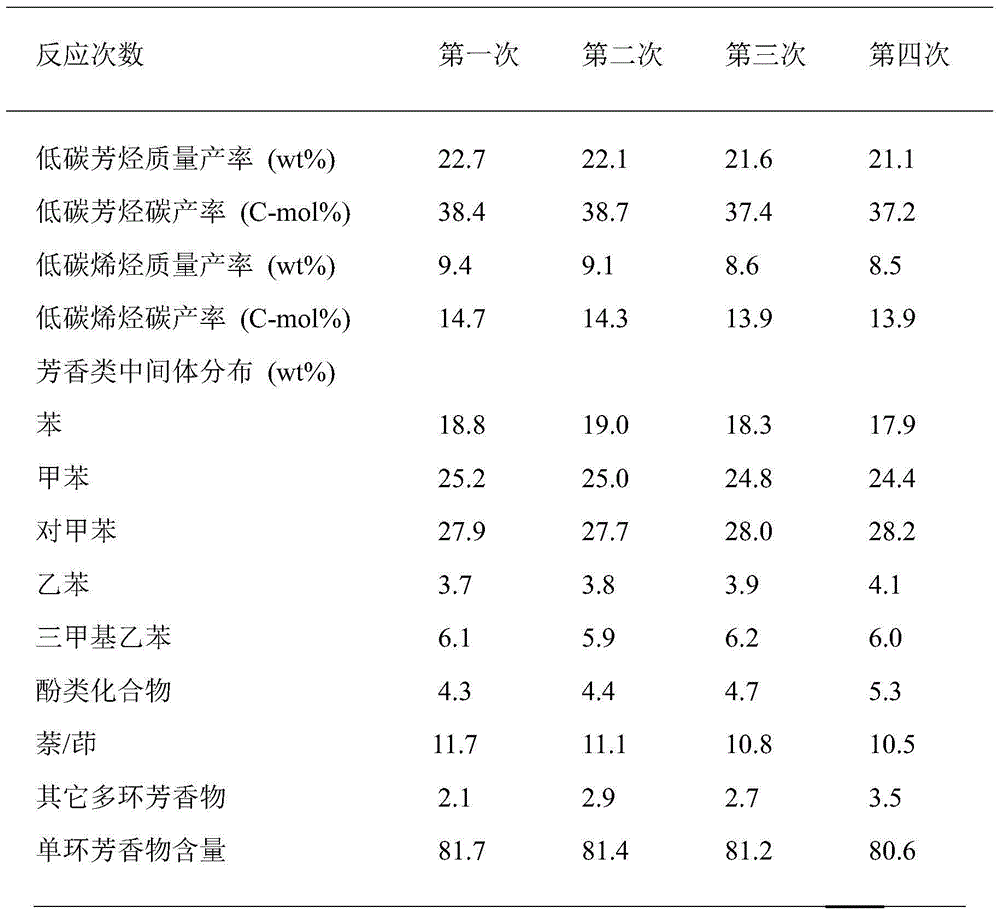

[0037] Catalyst stability in catalytic cracking and deoxygenation of wood chips to light aromatics and light olefins:

[0038] This example is intended to illustrate the effect of converting wood chips into low-carbon aromatics and low-carbon olefins and the stability of the catalyst by catalytic cracking and deoxygenation of wood chips, but does not limit this method.

[0039] In the process of this embodiment, the wood chip raw material used and the wood chip catalytic cracking and deoxygenation reactor used are the same as those used in Example 1. The catalyst used for wood chip catalytic cracking and deoxygenation is 7.6wt% NiO / 5.2wt% MgO / 87.2wt% Al-MCM-41 catalyst. The preparation steps of the catalyst are as follows: weigh 5.88g of commercially available nickel nitrate hexahydrate and 6.67g of magnesium nitrate hexahydrate, add 100mL of deionized water, and configure a nitrate mixed solution; then add 17.44g of commercially available Al-MCM-41 Molecular sieve powder is ...

Embodiment 3

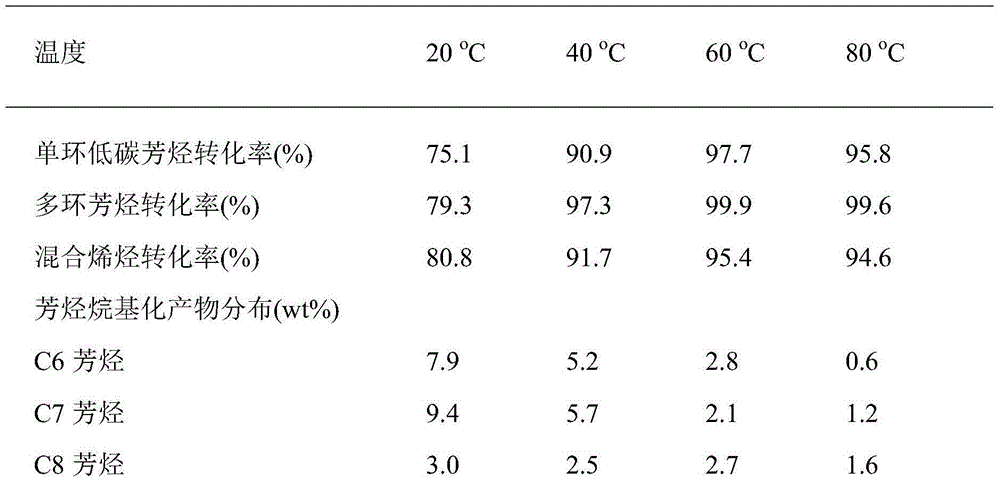

[0045] Influence of temperature during the directional conversion of low-carbon aromatics to kerosene range C9-C14 aromatics:

[0046] This example aims to illustrate the effect of directional conversion of low-carbon aromatics obtained by catalytic cracking and deoxygenation of sawdust into aromatics in the C9-C14 kerosene range by using the electrophilic substitution reaction of aromatics and the effect of temperature, but the method is not limited thereby.

[0047] In this example, the raw material of low-carbon aromatics is the mixture of low-carbon aromatics produced by catalytic depolymerization and deoxygenation of sawdust at 450° C. in Example 1. In order to maximize the use of biomass raw materials, the C2-C4 low-carbon olefin mixed tail gas obtained by catalytic cracking of wood chips under the condition of 450 ° C in Example 1 is used as the alkylating agent in the process of electrophilic substitution reaction of aromatics, and the tail gas of catalytic cracking of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com