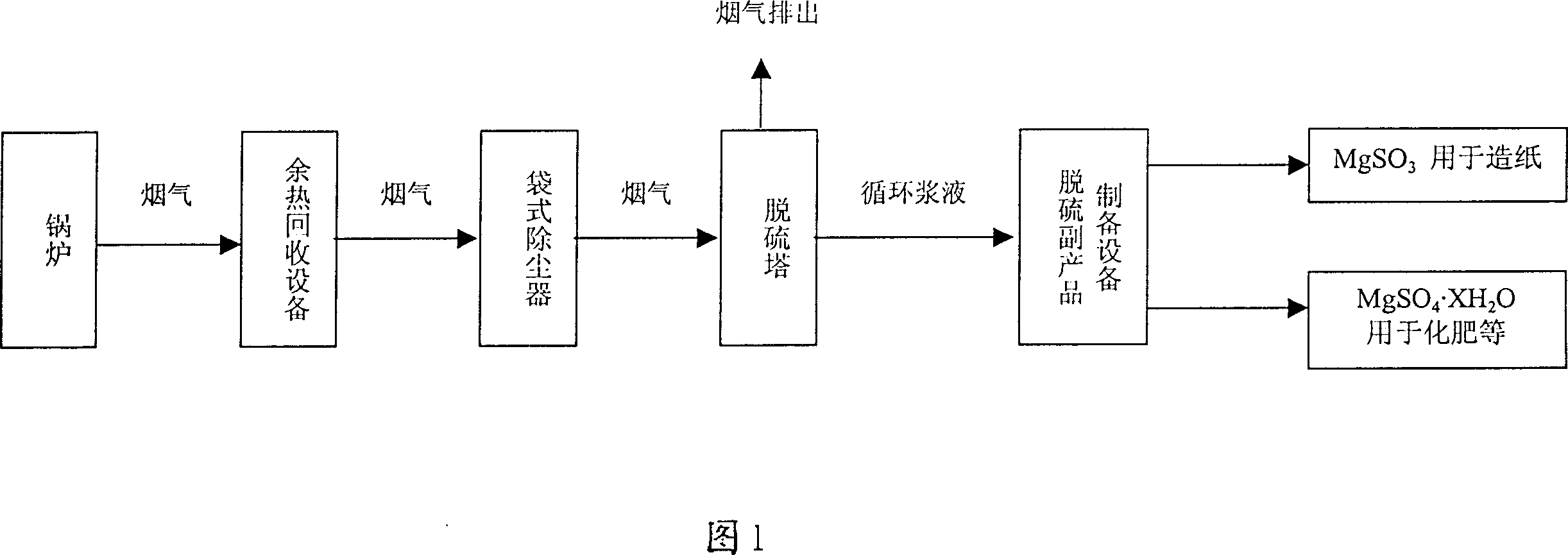

Integrating apparatus fo magnesium oxide with desulfurizing, dust-collecting and energy-saving functions and its production

A bag filter and waste heat recovery device technology, applied in chemical instruments and methods, separation methods, energy-saving heating/cooling, etc., can solve the problems of high exhaust gas temperature and boiler efficiency, and achieve great advantages, high economic value, The effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

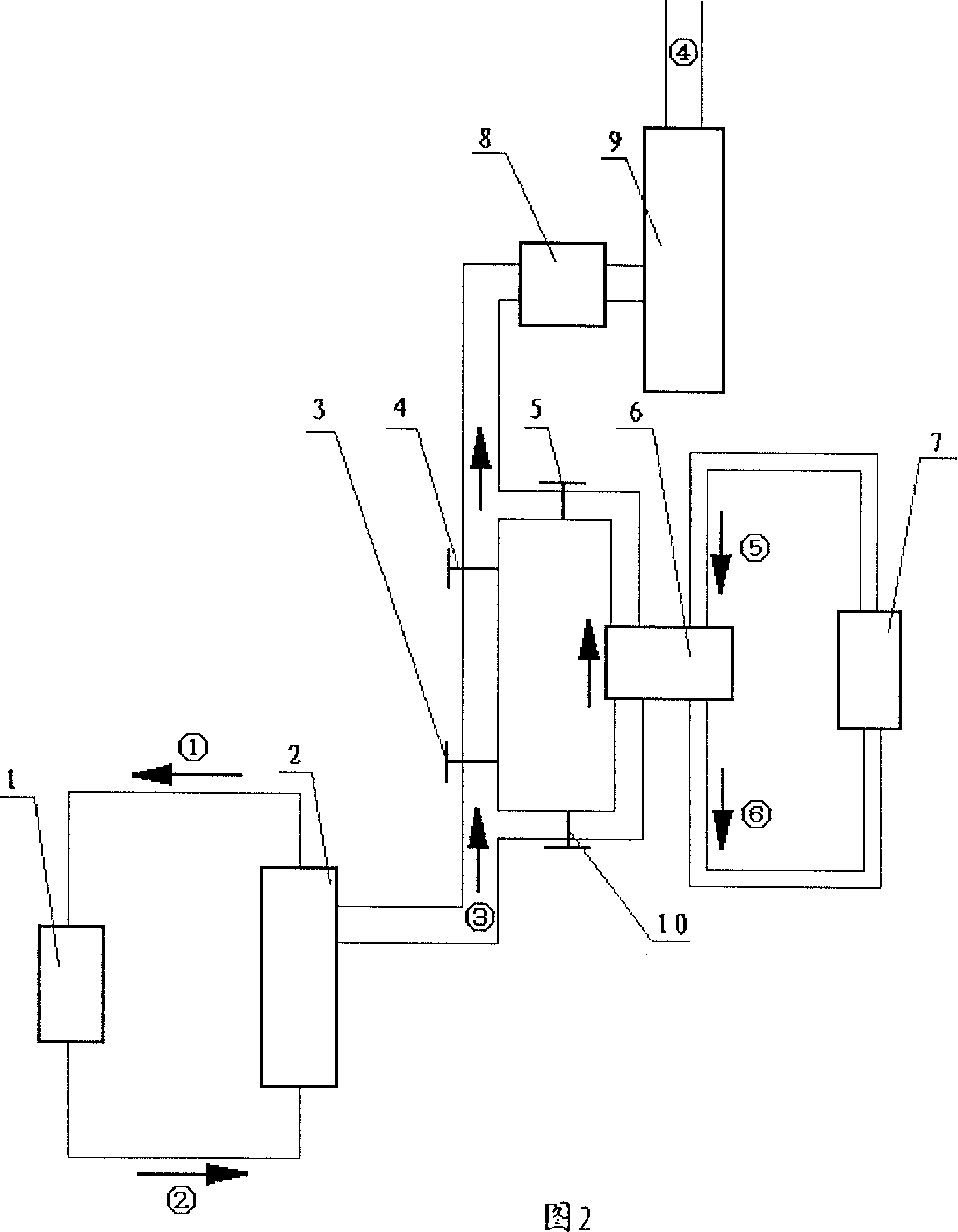

[0023] In Fig. 2, the boiler (2) provides hot water or steam to the heat user or steam user (1), the flue gas damper 1 (3), the flue gas damper 2 (4) are closed, and the flue gas damper 3 (5 ), the flue gas baffle plate 4 (10) is opened, the flue gas from the boiler (2) enters the ultra-speed superconducting heat pipe waste heat recovery device (6) to exchange heat with cold water, and the hot water after heat exchange is provided to the hot water user (7) for use. The heated flue gas enters the bag filter (8) for dedusting, the dedusted flue gas enters the magnesium oxide desulfurization tower (9) for desulfurization, and the desulfurized flue gas is discharged to the atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com