Hierarchical phase-change hot water storage tank

A phase-change heat storage, hierarchical technology, applied in the direction of solar heat storage, heat storage equipment, heating devices, etc., can solve the problems of uneven cooling and heating of water, large space occupation, poor user experience, etc., to improve heat exchange area, improve heat conversion efficiency, and overcome the effect of water temperature zoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

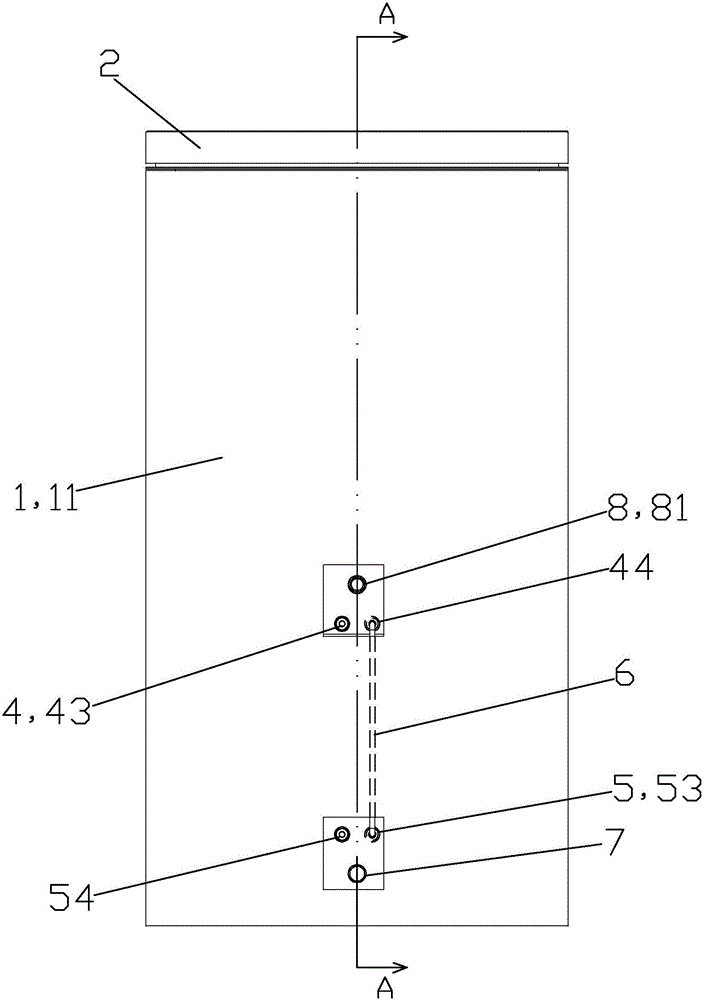

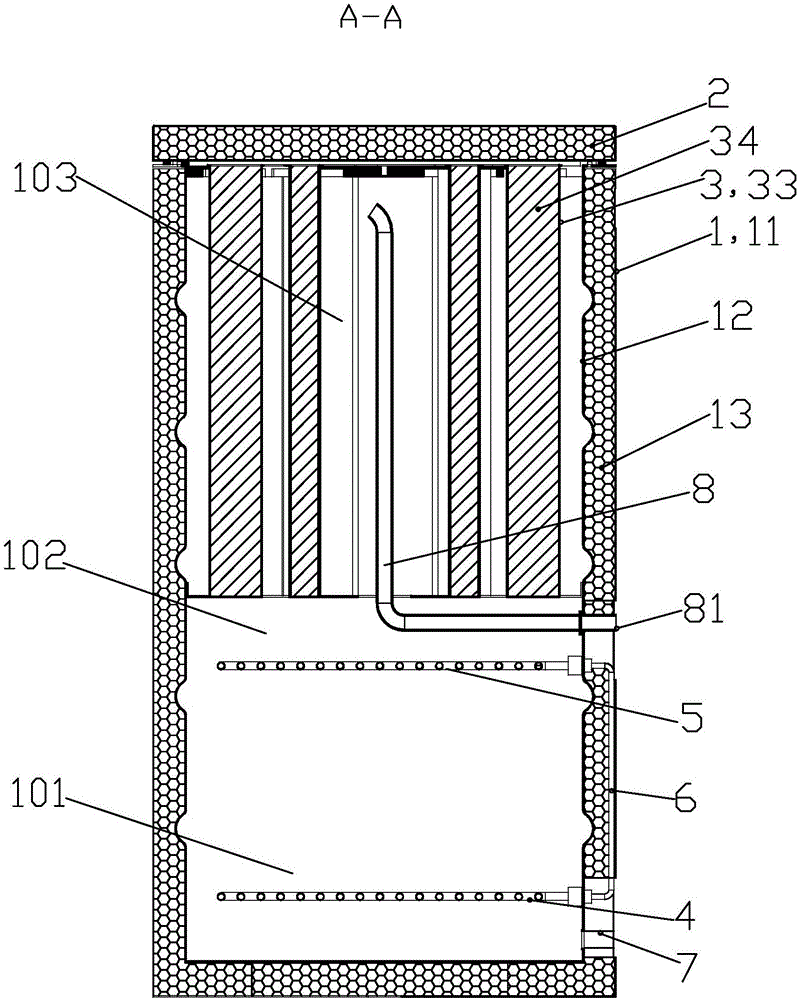

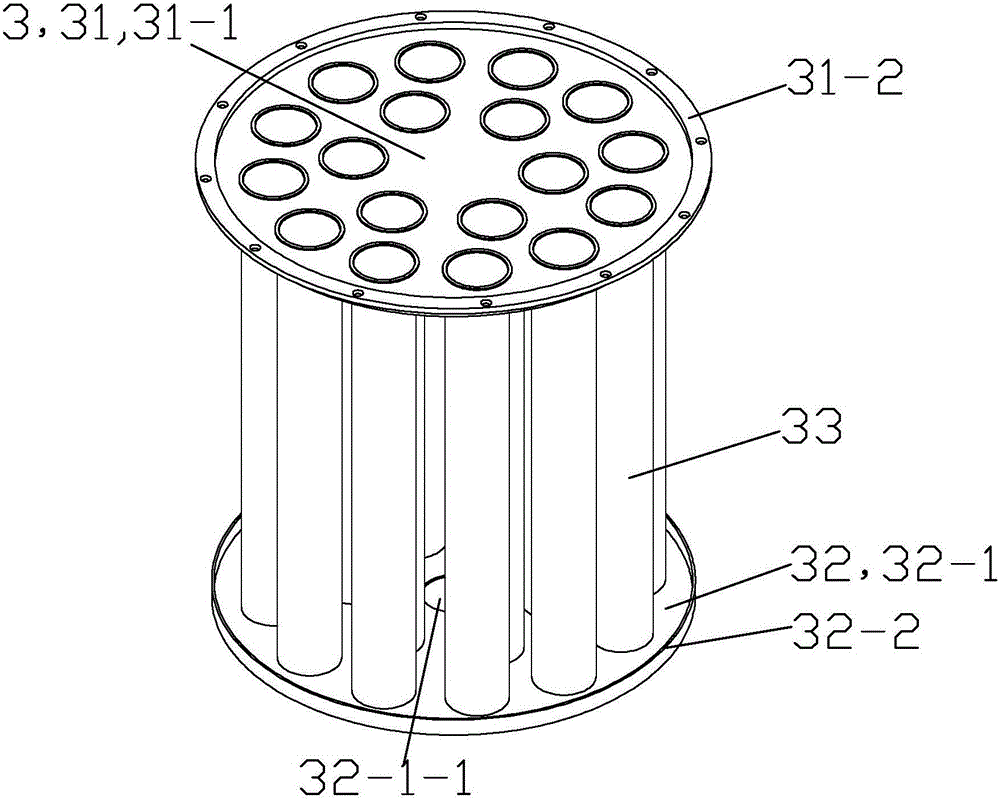

[0035] See Figure 1 to Figure 6 , the hierarchical phase change hot water storage tank of this embodiment mainly consists of a tank body 1, an upper cover 2, a phase change heat storage device 3, a first coil assembly 4, a second coil assembly 5, a connecting pipe 6, The water inlet nozzle 7 and the water outlet pipe 8 are formed.

[0036]The box body 1 is preferably a hollow cylinder with an open upper end in this embodiment; obviously, the box body 1 can also adopt other shapes such as a square. The casing 1 is mainly composed of an outer shell 11, an inner container 12, and an insulating layer 13 arranged between the outer shell 11 and the inner container 12; the inner container 12 is preferably an enamel inner container in this embodiment; the material of the insulating layer 13 is preferably Polyurethane foam insulation material is used. The lower part of the middle part of the side wall of the box body 1 is provided with a water nozzle installation hole and a refriger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com