Construction method for well structure of heat exchanging type horizontal butt-joint geothermal well

A construction method and shaft structure technology, applied in geothermal energy, geothermal energy power generation, geothermal collectors, etc., can solve problems such as water intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

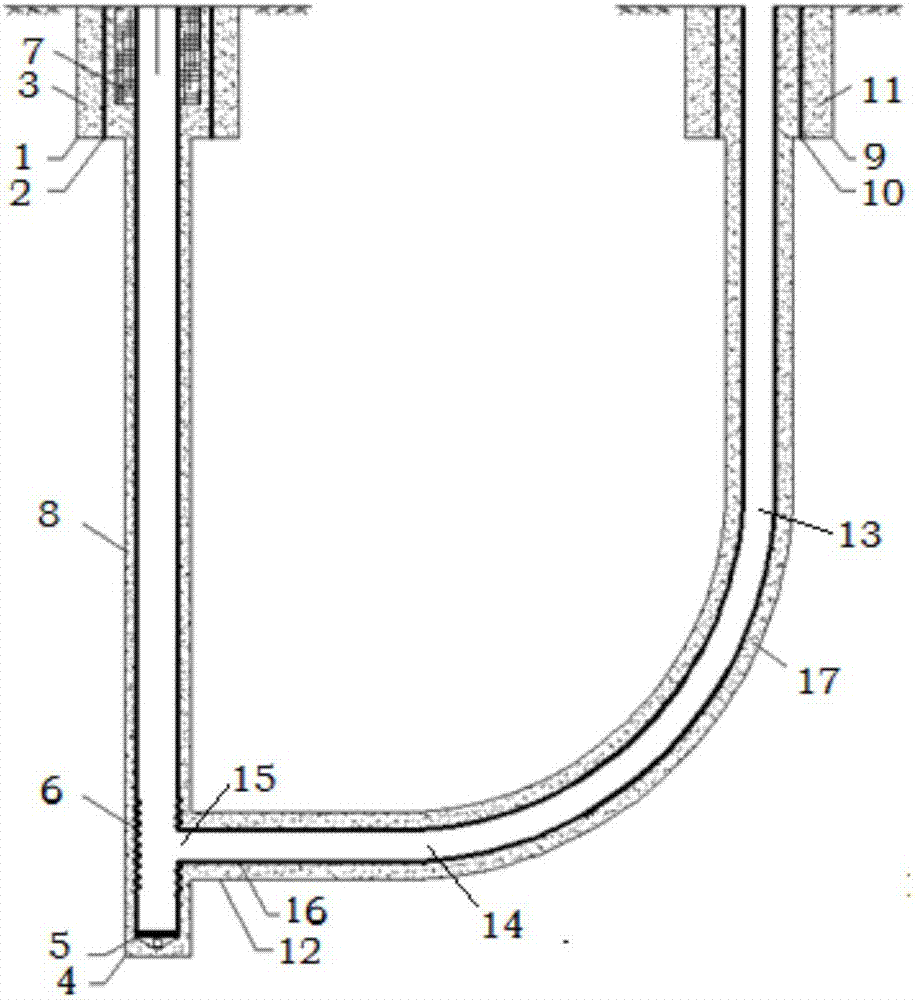

[0047] Such as figure 1 As shown, the present invention provides a well body structure of a heat-exchanging horizontal butt-connected geothermal well, including a vertical well and a horizontal engineering well, wherein the vertical well and the horizontal engineering well are butted and connected at the bottom, and the overall structure is U-shaped.

[0048] Wherein, the vertical well includes the first borehole 1 of the straight well and the second borehole 4 of the straight well. 1 to a mudstone layer with a thickness > 6m in the target thermal reservoir.

[0049] In the vertical well-opening borehole 1, a vertical well-opening casing 2 is arranged from the surface to the bottom of the vertical well-opening borehole 1. The vertical well-opening casing 2 includes several pieces with an outer diameter of 339.7mm, a wall thickness of 9.65mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com