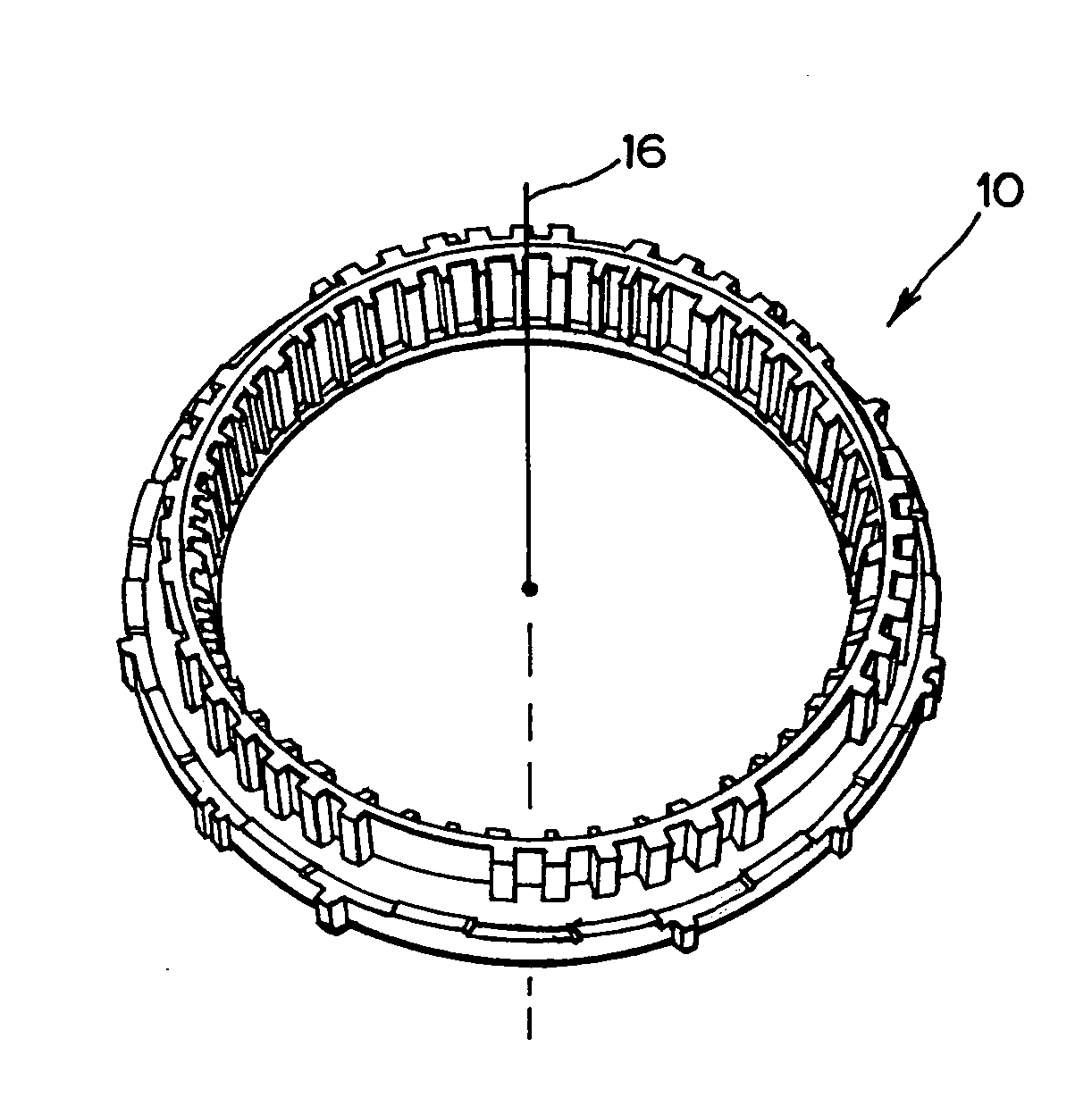

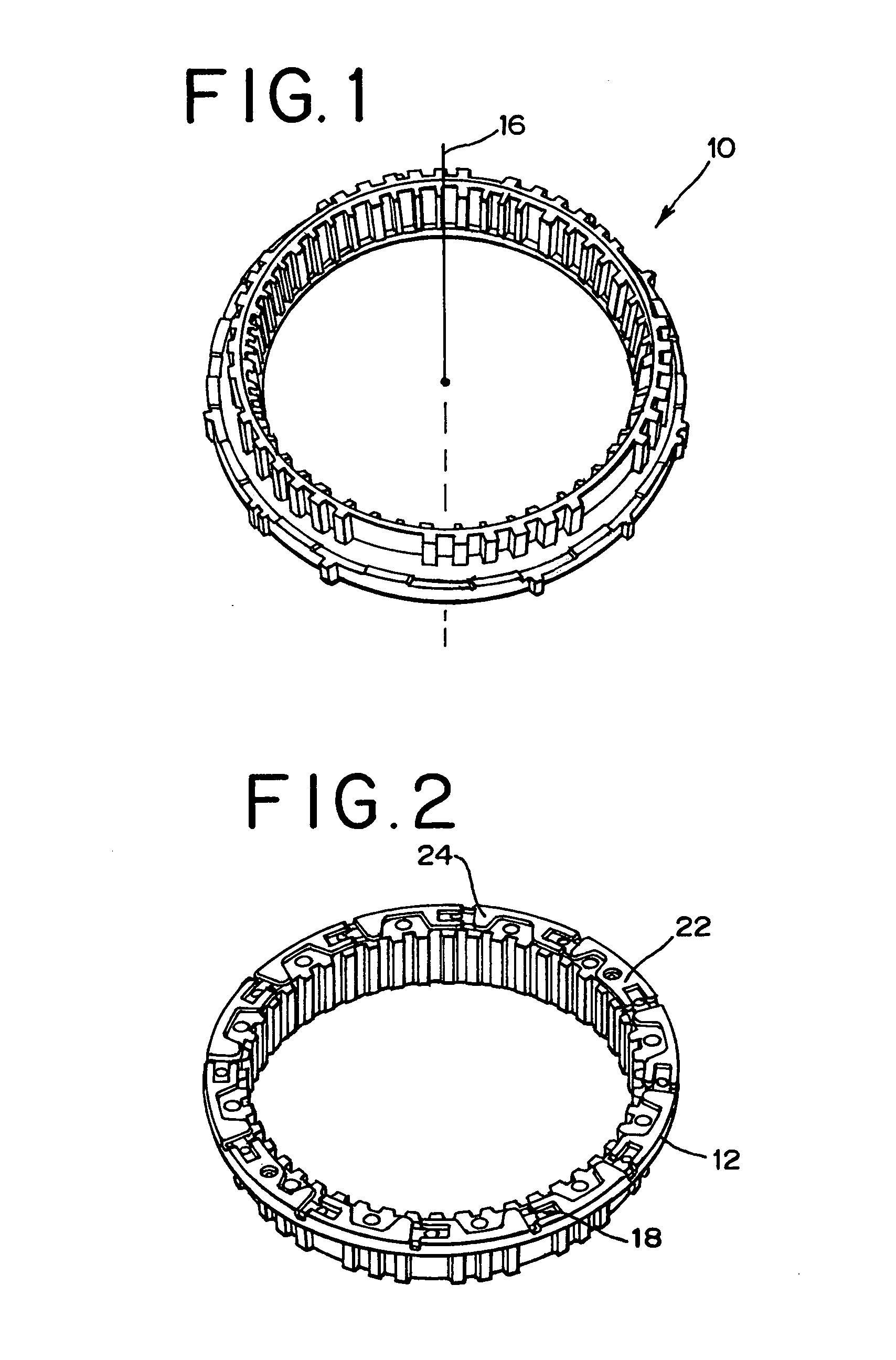

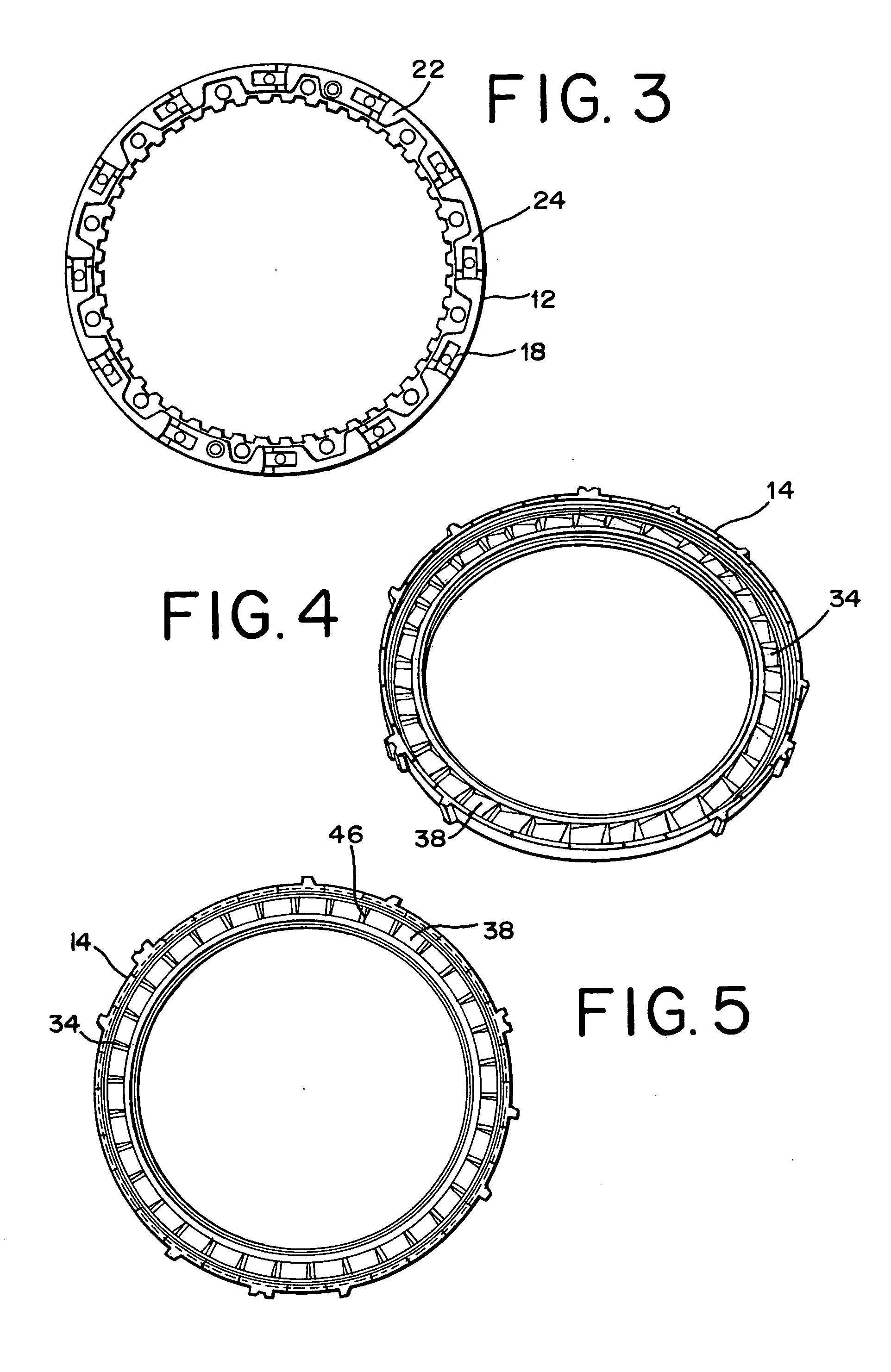

Manufacture of clutch components

a technology of clutch components and components, applied in the direction of transportation and packaging, metal-working apparatus, etc., can solve the problems of material's propensity to crack propagation in the finished component, and achieve the effects of low hardenability, aggressive cooling or quenching operation, and strong martensitic wear resistance hard structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0023]In a method of manufacturing an automotive clutch component, an initial pre alloy metal powder of particle sizes between 250 and 1 micron was provided comprising, by weight, 0.45% nickel, 0.65% molybdenum, with the balance essentially iron.

[0024]An additional 0.7% graphite, and 1.75% copper metal powder of particle sizes between 150 and 1 micron, by weight, were admixed to form an admixed metal powder.

[0025]0.5% EBS was added as a lubricant to form a lubricated admixed metal powder.

[0026]The lubricated, admixed metal powder was compacted at a pressure of 45 tons per square inch.

[0027]The die compacted metal blank was then sintered at a temperature 2050° F. for 15 minutes.

[0028]The sintered metal blank was then quenched at a rate of 5.4° F. (3.00° C.) per second from an initial temperature of (2000° F.) (1090° C.) to a temperature of (500° F.) (260° C.) per use. The quenched metal blank was then tempered at a temperature of (380° F.) (190° C.) for 60 minutes.

[0029]The resulting...

example 2

[0030]In a method of manufacturing an automotive clutch component, an initial pre alloy metal powder of particle sizes between 250 and 1 microns was provided comprising, by weight, 0.45% nickel, 0.65% molybdenum, with the balance essentially iron.

[0031]An additional 0.9% graphite, and 1.75% copper metal powder of particle size between 150 and 1 micron, by weight, were admixed to form an admixed metal powder.

[0032]0.5% EBS was added as a lubricant to form a lubricated admixed metal powder.

[0033]The lubricated, admixed metal powder was compacted at a pressure of 45 tons per square inch.

[0034]The die compacted metal blank was then sintered at a temperature 2050° F. for 15 minutes.

[0035]The sintered metal blank was then quenched at a rate of 1.9° F. (1.05° C.) per second from an initial temperature of (2000° F.) (1090° C.) to a temperature of (500° F.) (260° C.) per use. The quenched metal blank was then tempered at a temperature of (380° F.) (1090° C.) for 60 minutes.

[0036]The resultin...

example 3

[0037]In a method of manufacturing an automotive clutch component, an initial pre alloy metal powder of particle size between 250 and 1 micron was provided comprising, by weight, 0.45% nickel, 0.65% molybdenum, with the balance essentially iron.

[0038]An additional 0.9% carbon, and 1.75% copper metal powder of particle size between 150 and 1 micron, by weight, were admixed to form an admixed metal powder.

[0039]5% EBS was added as a lubricant to form a lubricated admixed metal powder.

[0040]The lubricated, admixed metal powder was compacted at a pressure of 45 tons per square inch.

[0041]The die compacted metal blank was then sintered at a temperature 2050 for 15 minutes.

[0042]The sintered metal blank was then quenched at a rate of 1.9° F. (1.0° C.) per second from an initial temperature of (2000° F.) (1090° C.) to a temperature of (500° F.) (260° C.) per use. The quenched metal blank was then tempered at a temperature of (380° F.) (190° C.) for 60 minutes.

[0043]The resulting material h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com