Method for preparing anode of microorganism fuel battery with graphene and ferrous disulfide compound

An iron disulfide and fuel cell technology, applied in the fields of materials, energy, and environment, can solve the problems of complex synthesis procedures, low yield, harsh reaction conditions, etc., and achieve the effects of simple synthesis steps, uniform particle morphology, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: a kind of preparation method of the microbial fuel cell anode of load graphene and iron disulfide compound, described method specific steps are as follows:

[0020] Step 1: Drop ferric chloride and thiourea solution into the graphene oxide dispersion liquid in the reaction kettle drop by drop, and after stirring evenly, seal the reaction kettle, and keep the temperature between 140°C and 200°C (the optimum temperature is 180 o C) Hydrothermal reaction between 12 to 24 hours (the best reaction time is 12 hours), to obtain a hydrogel sample;

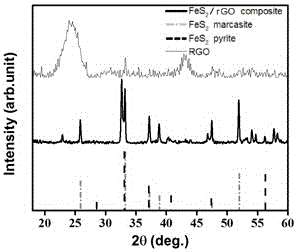

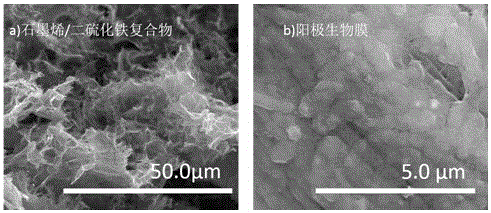

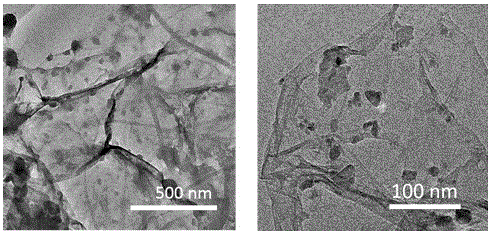

[0021] Step 2: Wash the hydrogel sample several times with deionized water, freeze-dry and pulverize to obtain graphene and iron disulfide composite nanopowder; perform X-ray crystal diffraction test on it, and it can be known that iron disulfide There are two crystal forms of marcasite and pyrite ( figure 1 ); From the scanning electron microscope image of the prepared graphene and iron disulfide composite...

specific Embodiment approach 2

[0024] Specific embodiment two: the preparation method of the microbial fuel cell anode of a kind of loaded graphene and ferric disulfide compound described in specific embodiment one, in step one, the mol ratio of ferric chloride and thiourea is 6.8:5 , the mass of thiourea is 2.0*10 of that of graphene oxide 3 times.

specific Embodiment approach 3

[0025] Specific embodiment three: the preparation method of a microbial fuel cell anode loaded with graphene and iron disulfide composite described in specific embodiment one, in step three, the Nafion solution of 7.5 μ L of 5% is used for each milligram of the nanopowder (Binder), isopropanol and deionized water are not less than 1 / 2 and 1 / 7 of the Nafion solution volume, and can be increased appropriately according to the actual situation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com