Low-power ventilating fan

A ventilation fan and low-power technology, applied in the direction of non-variable pumps, pump devices, machines/engines, etc., can solve the problems of high manufacturing cost, unsteady operation, uncertain rotation direction, etc., and achieve the effect that is beneficial to structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

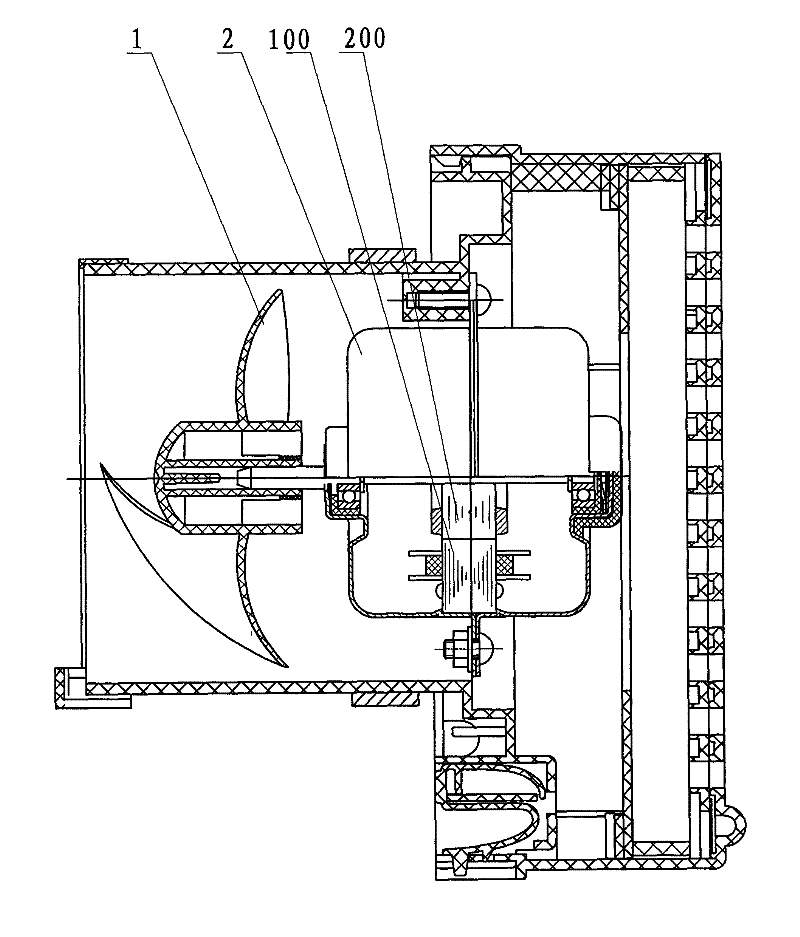

[0049] The basic mechanical structure of the ventilation fan in the embodiment of the present invention is as follows: figure 1 shown. This is a low-power axial flow ventilation fan, mainly including:

[0050] - motor 2 fixed to the casing;

[0051] ——An axial-flow impeller 1 directly connected to the output shaft of the motor and rotating counterclockwise has 4 blades; according to wind pressure requirements, the number of blades can also be 3, 5 or 6, but preferably not more than 8, And as odd as possible to reduce vibration noise. The impeller is injection molded with a diameter of 100mm. The maximum diameter of the impeller should not exceed 150mm, and the moment of inertia should be as small as possible to match the starting torque of the motor 2 which is still not too large;

[0052] ——The motor 2 is an inner rotor motor, including a stator 100 and a permanent magnet rotor 200 .

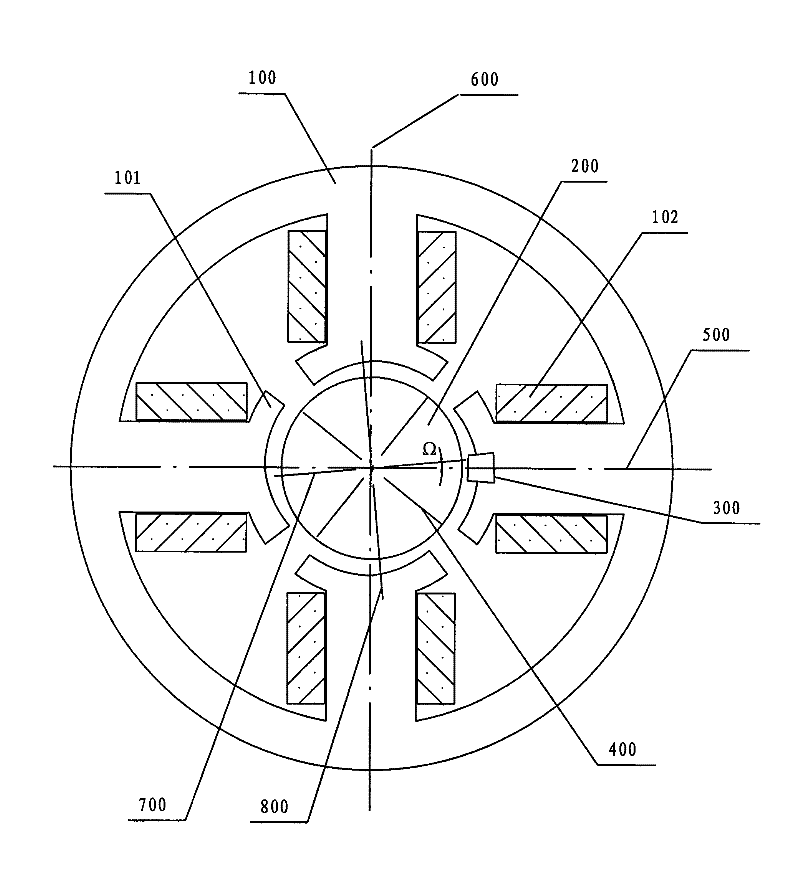

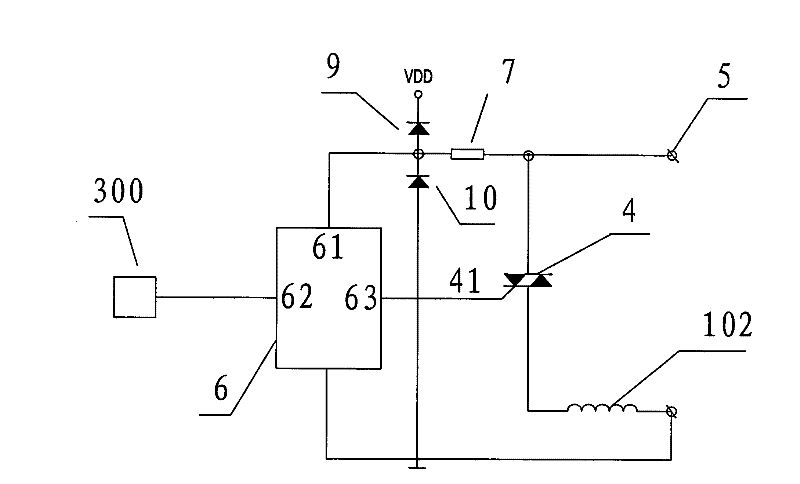

[0053] The basic electromagnetic structure of the electric motor of the ventilating fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com