Device for taking bearing ring casting part out

A technology for removing devices and castings, applied in the field of casting processing equipment, can solve the problems of workers falling, high temperature of bearing ring castings, and poor grasping between hooking tools and bearing ring castings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

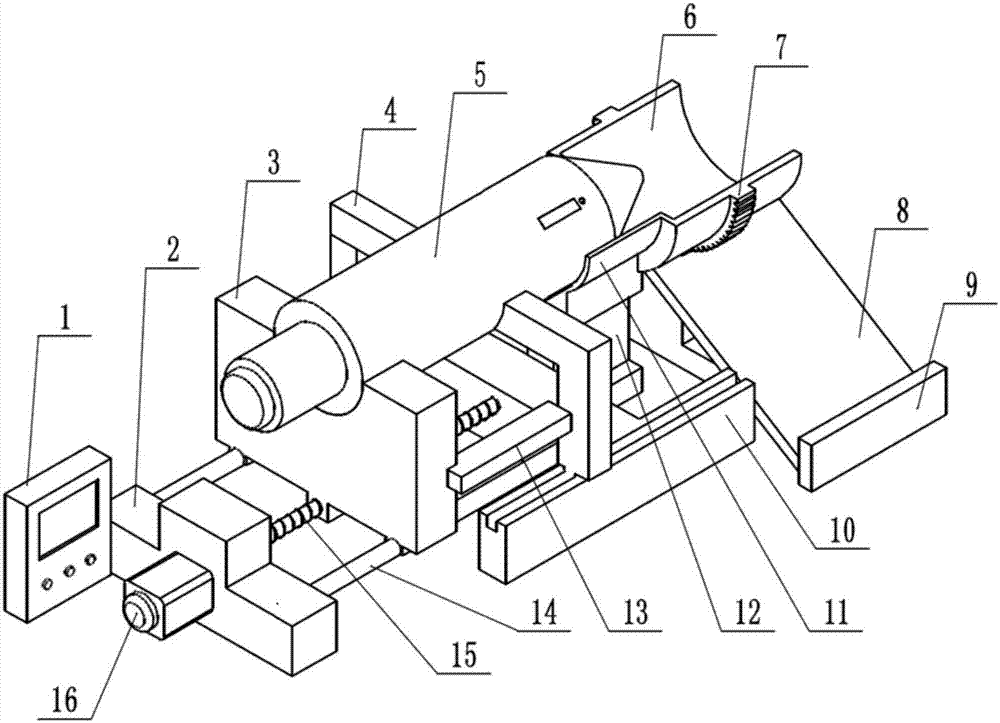

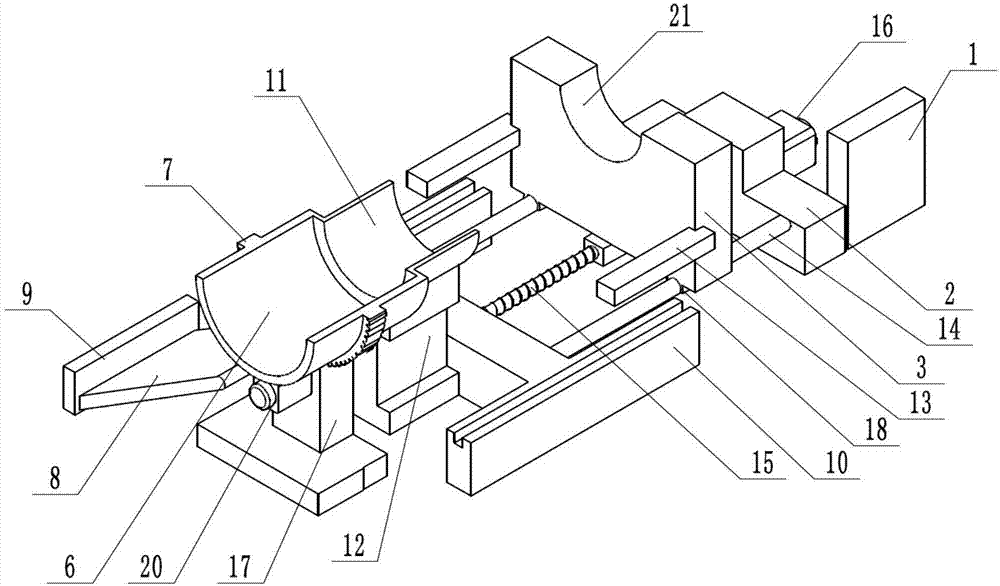

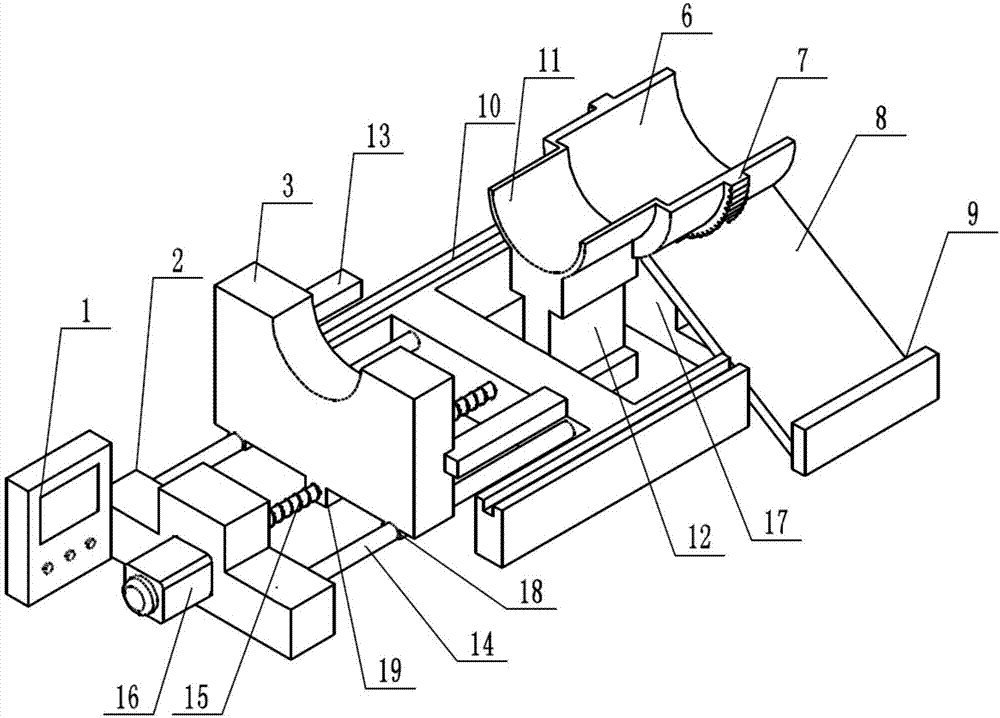

[0019] A bearing ring casting take-out device is composed of a control cabinet 1, a base 2, a bracket 3, a support frame 4, a support mechanism 5, an arc plate support 6, a rack 7, a slide plate 8, a baffle plate 9, Slide rail one 10, arc plate support two 11, support frame two 12, connecting rod 13, light rod 14, lead screw one 15, displacement motor 16, support frame three 17, sliding fitting block 18, displacement fitting block 19 and blanking Composed of motors 20, the displacement motor 16 is installed on the base 2, the control cabinet 1 is arranged on one side of the base 2, the output shaft of the displacement motor 16 is connected with a lead screw 15, the screw Both sides of bar one 15 are respectively provided with light rod 14, and described light rod 14 is installed on the leading screw one 15, and described light rod 14 cooperates with sliding fitting block 18, and described sliding fitting block 18 has two, two A displacement fit block 19 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com