Seedling nursery for seedling cultivation

A technology for nurseries and seedlings, applied in application, cultivation, greenhouse cultivation, etc., can solve the problems that it is difficult to ensure the soil moisture, light, and temperature of seedlings, and it is difficult to reduce the labor burden of planters, time-consuming and labor-intensive, etc., so as to reduce the amount of manual participation, Reduces labor burden and prevents burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A kind of nursery for cultivating nursery stock of the present invention is described in further detail below in conjunction with accompanying drawing and specific embodiment:

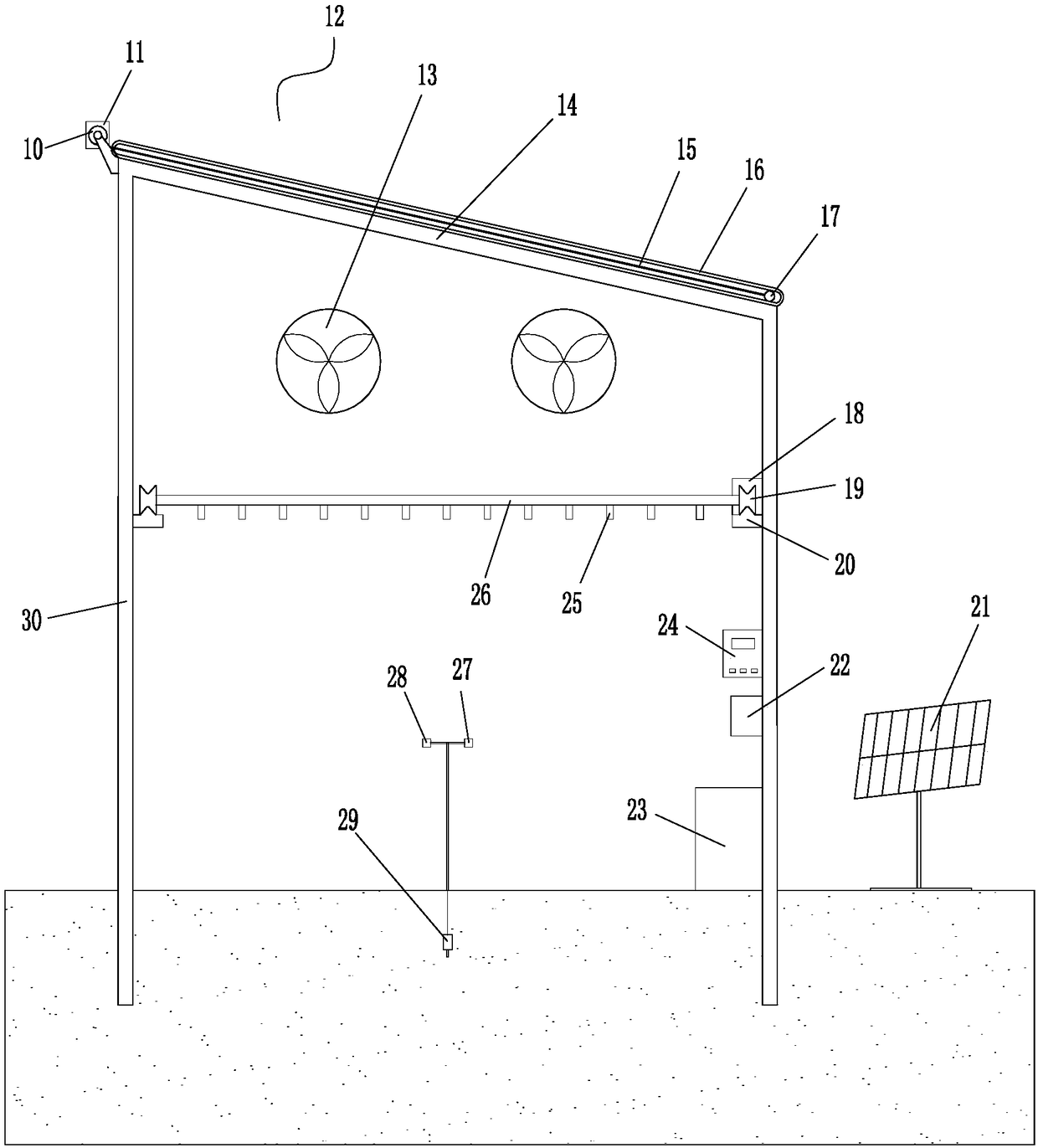

[0010] Such as figure 1 As shown, in this specific embodiment, a kind of nursery for cultivating seedlings of the present invention, comprises the greenhouse body 12 that is surrounded by skeleton 30 and plastic film, also comprises roller shutter motor 11, reel 10, sunshade net 15 , controller 24, light sensor 27, temperature sensor 28, exhaust fan 13, soil moisture sensor 29, water pump 22, cross bar 26 and some sprinklers 25 evenly distributed along the length direction of cross bar 26. The top of the greenhouse body 12 is a slope 14 inclined to one side. The slope 14 is facing the sun. The two ends of the shaft 17 are respectively located in the guide ring 16, and the guide ring 16 is obliquely installed on the top of the greenhouse body 12 to play a guiding role; Bearings are installed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com