Patents

Literature

47results about How to "Reduce the amount of manual involvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

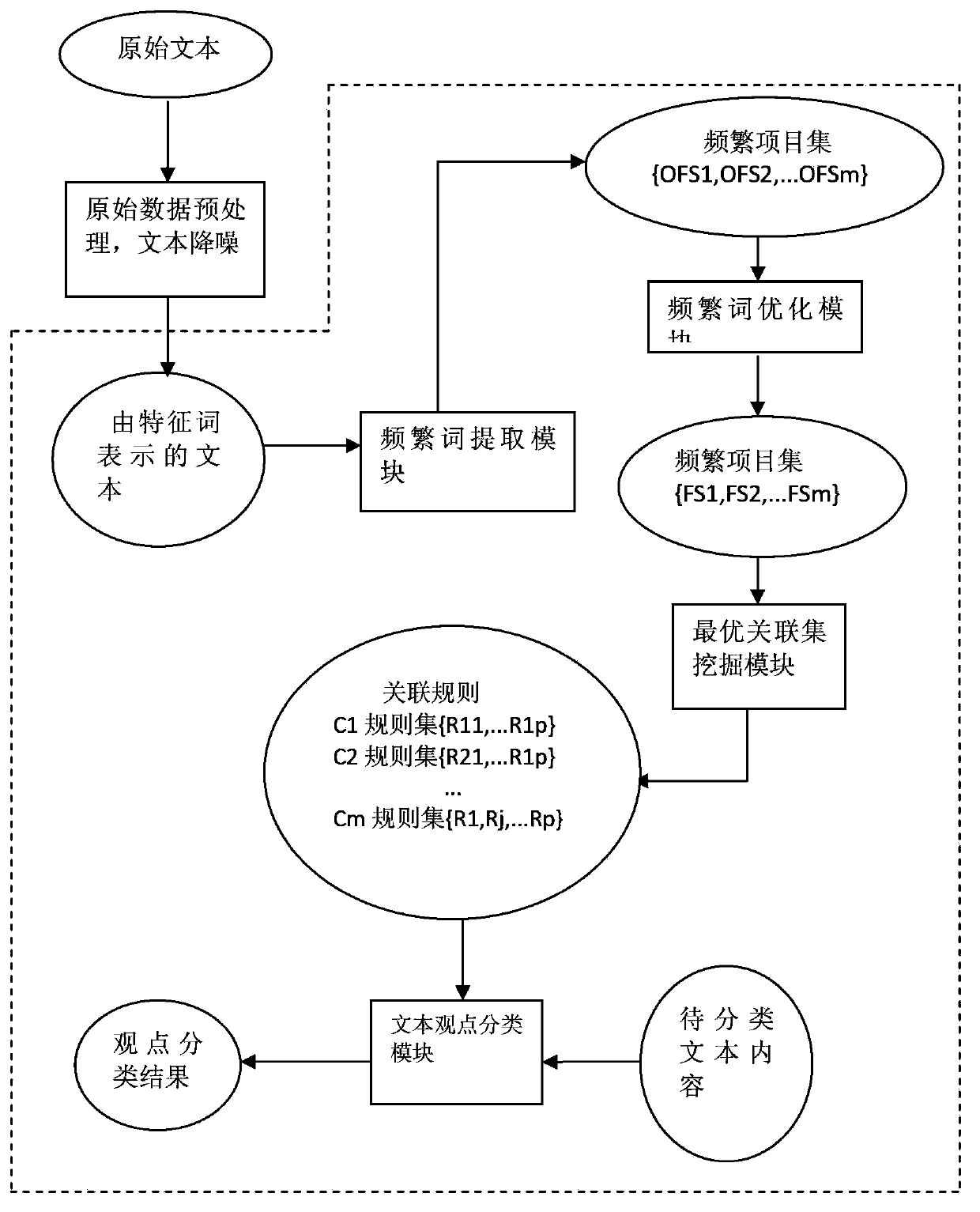

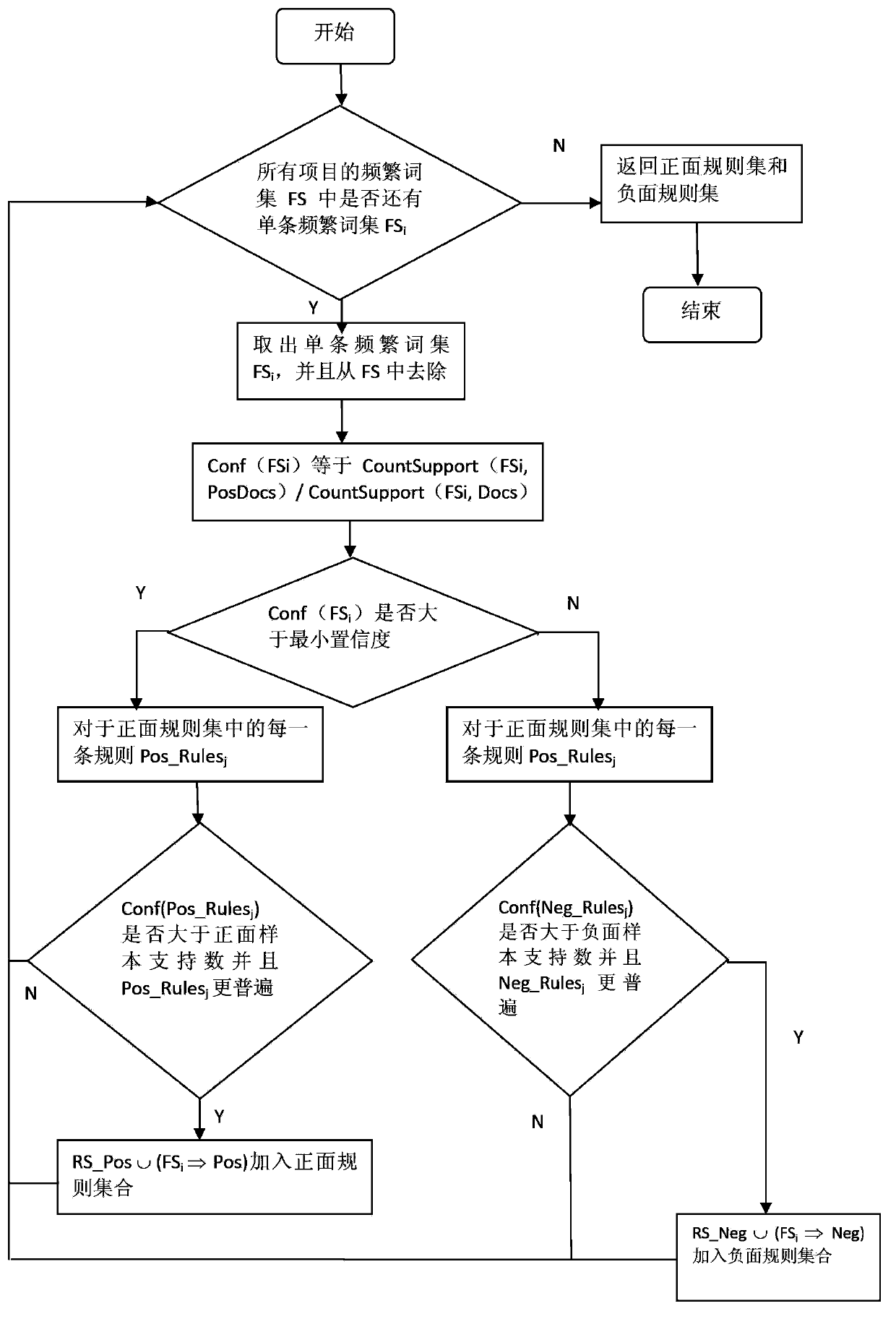

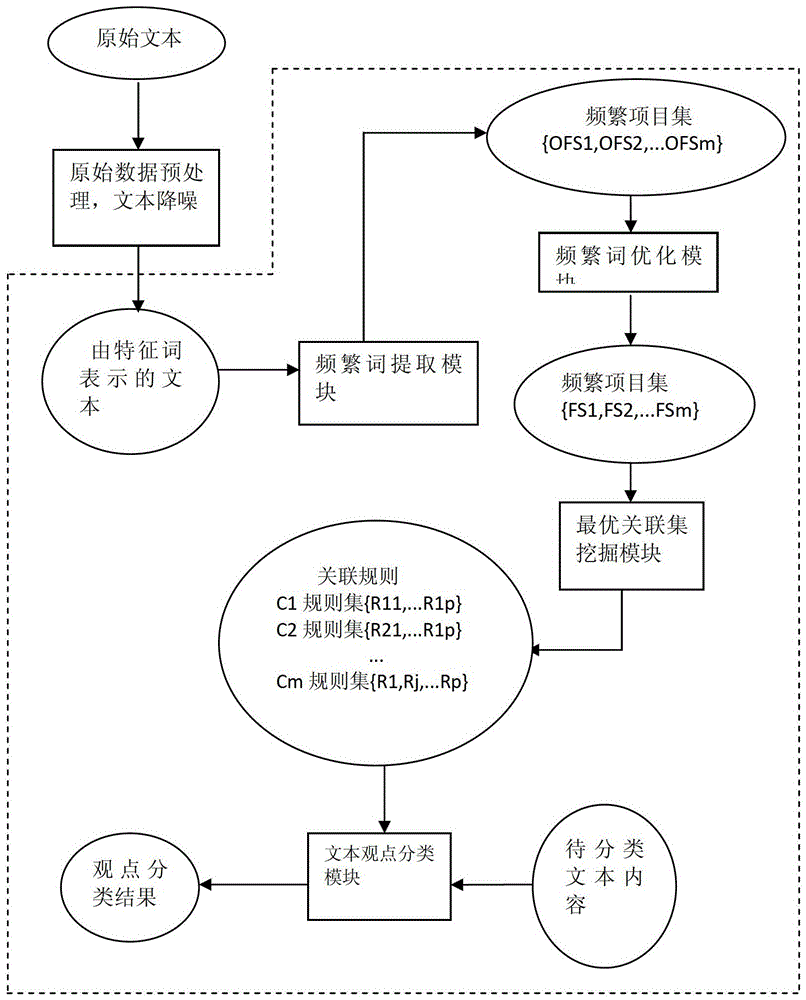

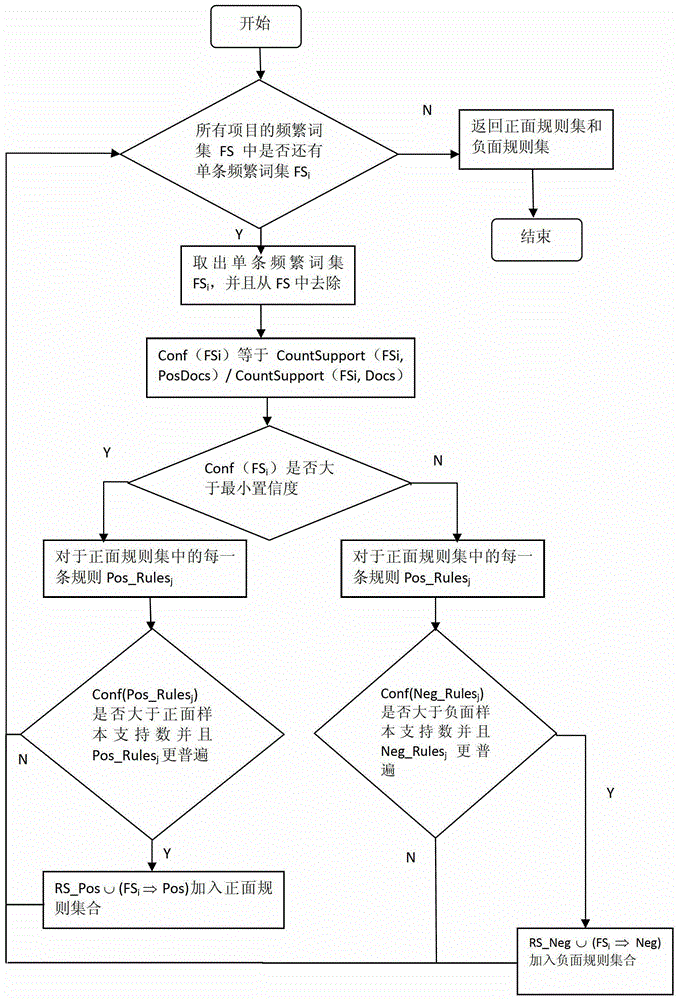

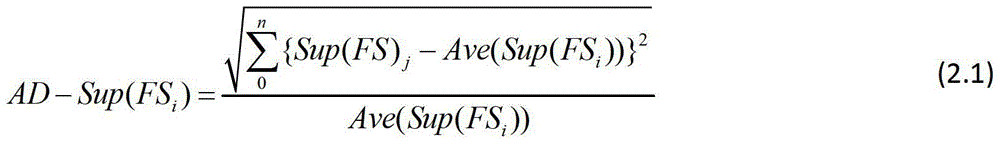

Automatic classification system and automatic classification method for Web comment viewpoint on the basis of association rule

ActiveCN103473262AGuaranteed uptimeImprove efficiencySpecial data processing applicationsViewpointsClassification methods

The invention discloses an automatic classification system and an automatic classification method for a Web comment viewpoint on the basis of an association rule. The automatic classification system can be divided into four modules, i.e. a frequent feature word extraction module, a frequent feature word optimization module, an association rule extracting and mining module and a viewpoint classification module. According to the invention, the defects that the traditional system (such as systems based on machine learning and sentiment classification) has low precision or needs mass manpower participation or excessively depends on natural language processing and professional knowledge can be overcome. Optimization is carried out in the association rule set extraction process, redundant association rules with low distinction degree are removed, and therefore, the operation efficiency and the result acquisition efficiency of the whole system can be improved. According to the invention, a precise and convenient solution is provided for various situations, such as E-business commodity evaluation, E-government affair feedback and netizen opinion survey.

Owner:珠海市颢腾智胜科技有限公司

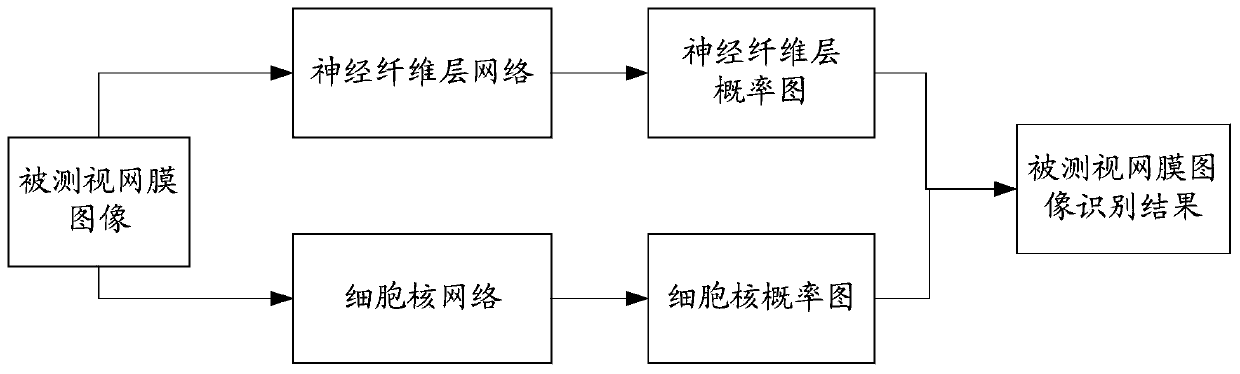

Retina pathological image analysis system based on machine learning

ActiveCN110853009AReduce the amount of manual involvementFast recognitionImage enhancementImage analysisMedicineImaging analysis

The invention provides a retina pathological image analysis system based on machine learning. The system comprises a retina original image sample acquisition module, an image graying processing module, a histogram specification module, an image normalization module, a nerve fiber layer marking module, a cell nucleus marking module, an image cutting module, a nerve fiber layer network training module, a cell nucleus network training module, a nerve fiber layer prediction module and a cell nucleus prediction module. The retina pathology image analysis system based on machine learning has the advantages that the retina pathology image analysis system based on machine learning has the following advantages. The retinal pathological image analysis system based on machine learning provided by theinvention is small in artificial participation amount, is suitable for large sample size analysis, has the advantages of high recognition speed and high recognition accuracy, and has more effective quantitative analysis and practical application prospects.

Owner:北京端点医药研究开发有限公司

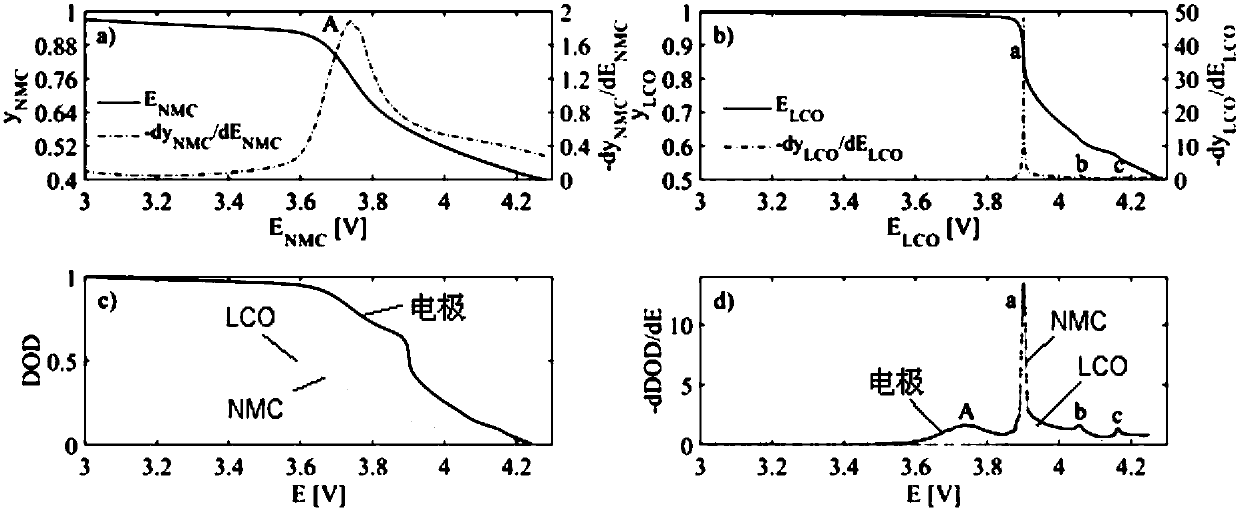

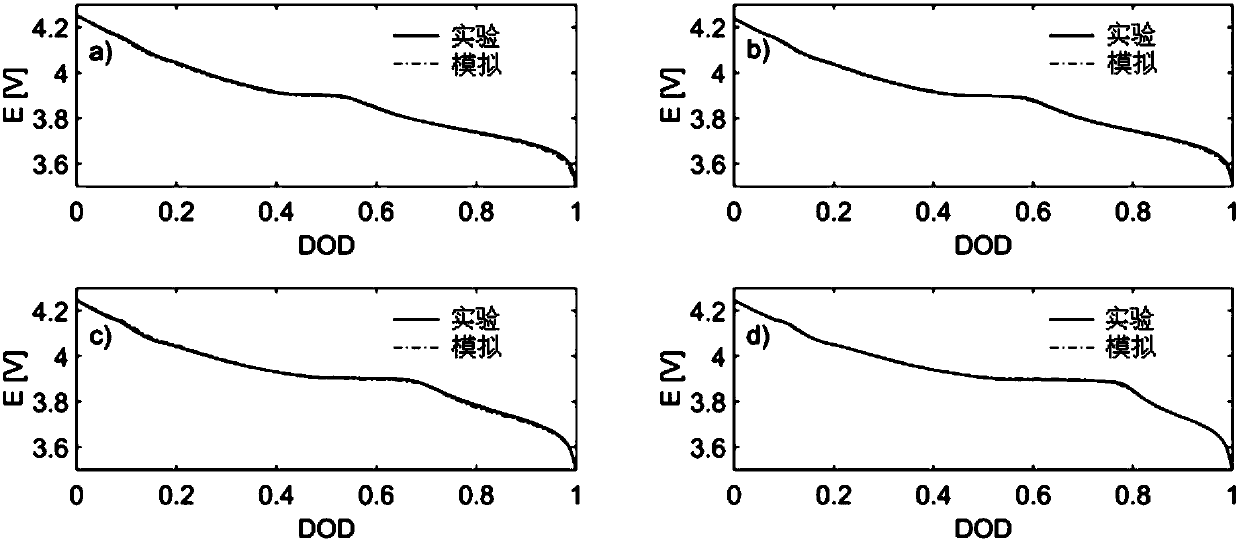

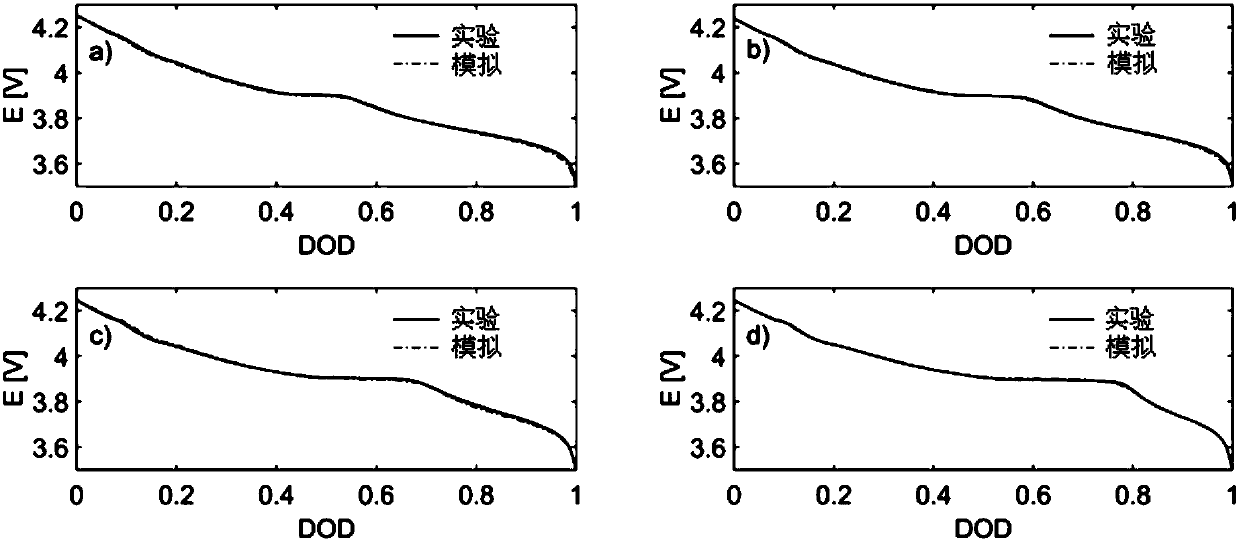

Detection method of composite electrode state

ActiveCN106405436AImplement internal state detectionRealize automated detectionElectrical testingElectricityComposite electrode

The invention discloses a detection method of a composite electrode state. The method comprises: step one, a lithium ion battery electrochemical model of a composite electrode is established and simplification is carried out to obtain a relationship, shown by two formulas, between internal parameters and external features of the composite electrode, wherein in the relationship, Cap expresses an electric quantity released during a battery testing process, Capa expresses an electricity quantity released in a battery testing zone, DOD expresses a discharging depth during the battery testing process, y1- and y2- express average lithium insertion amounts of a first active material and a second active material in the battery, y1,0- and y2,0- express initial lithium insertion amounts of the first active material and the second active material in the battery, and Dy1- and Dy2- express lithium insertion amount changing ranges of the first active material and the second active material in the battery testing zone; and step two, external features are measured and calculation is carried out based on a parameter identification method to obtain internal parameter information. According to the provided method, internal state detection of the composite electrode is realized under the circumstance that the battery is not damaged. The method that can be applied to any composite electrode system has high operability and practicality.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH

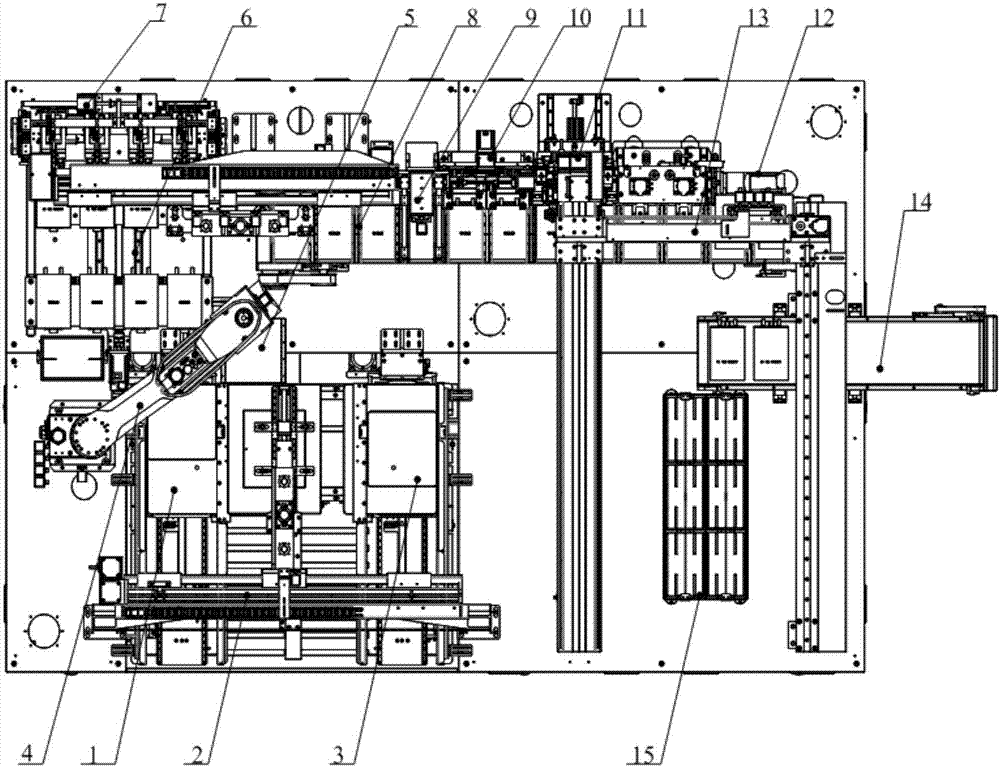

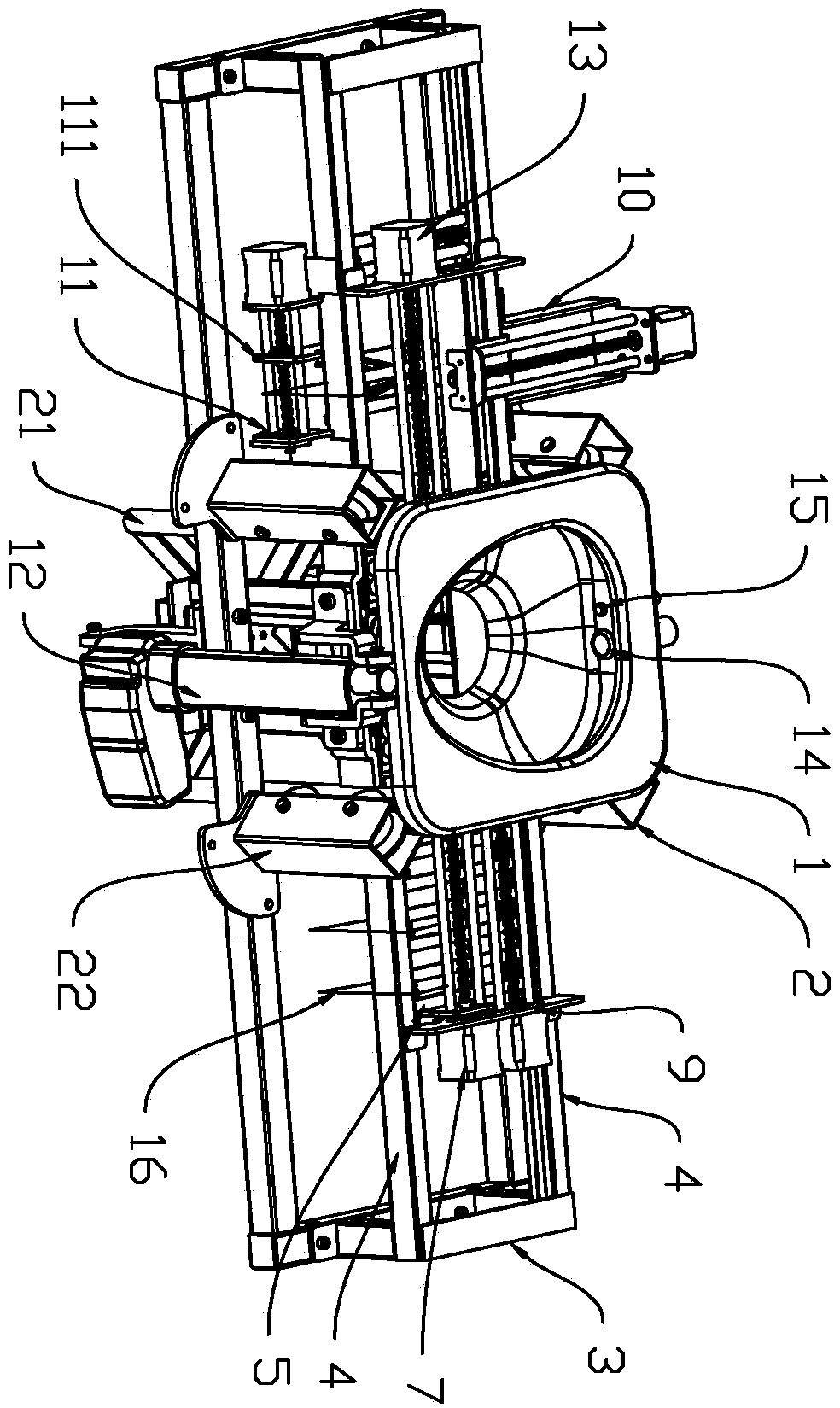

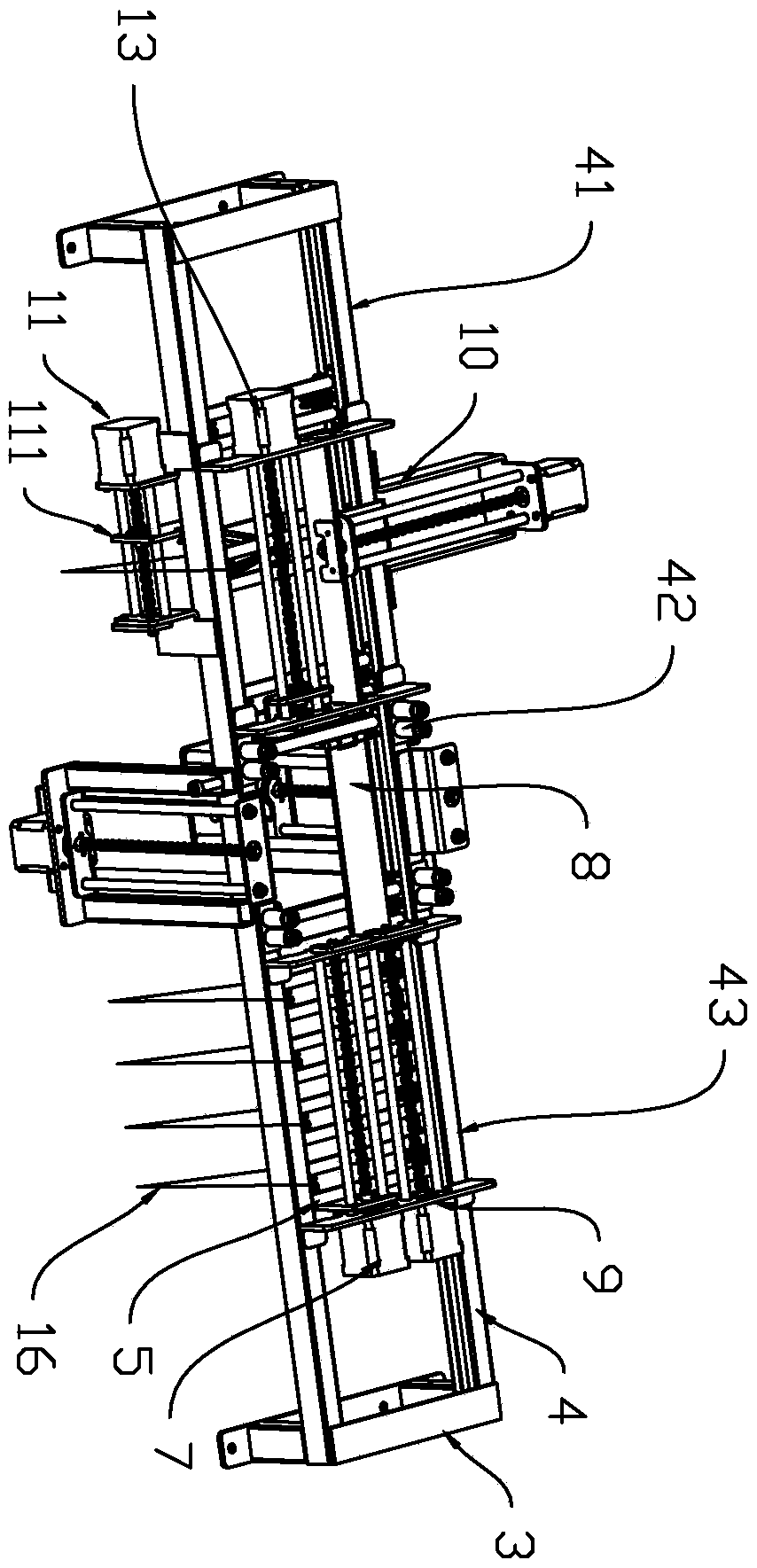

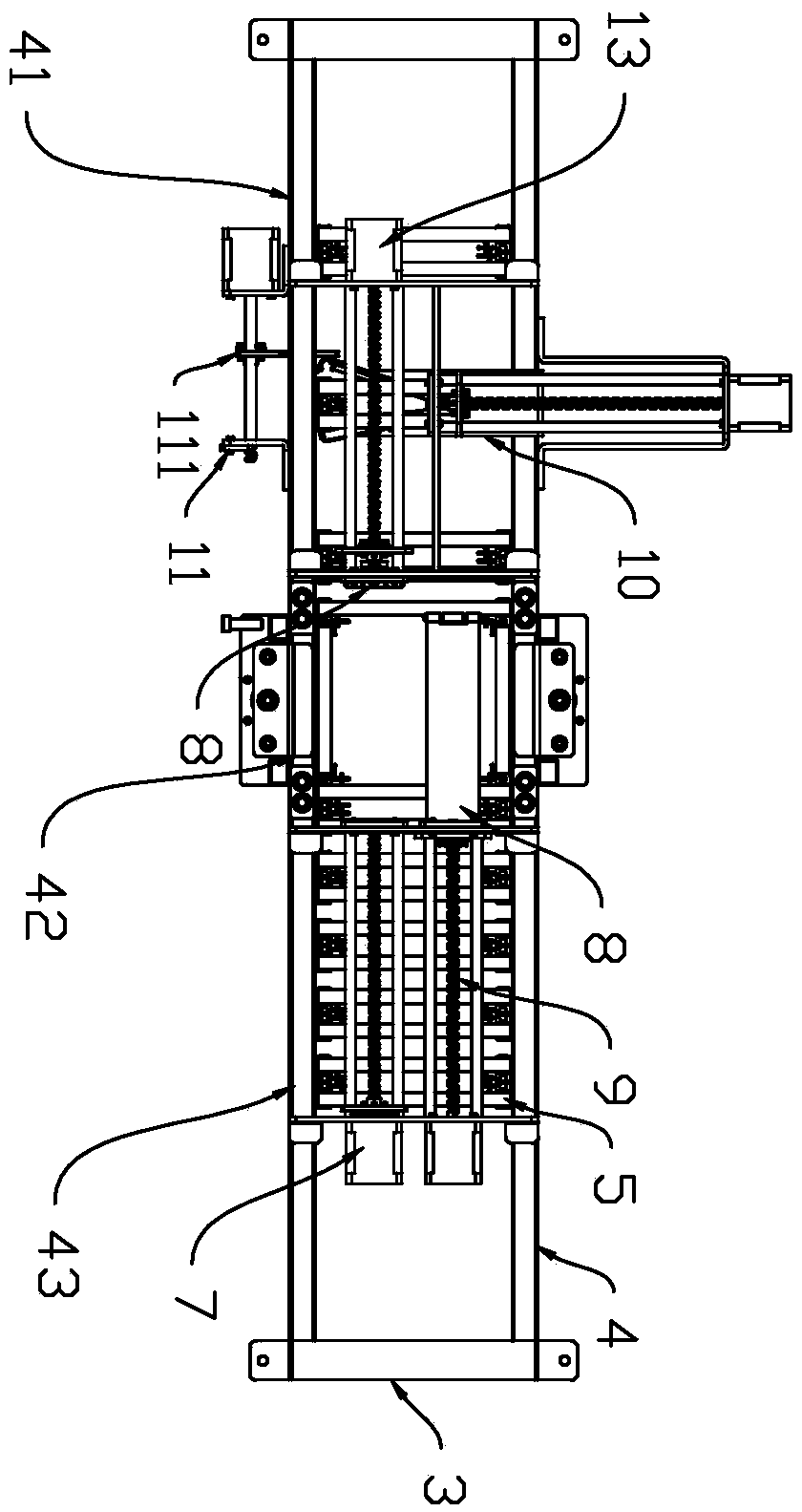

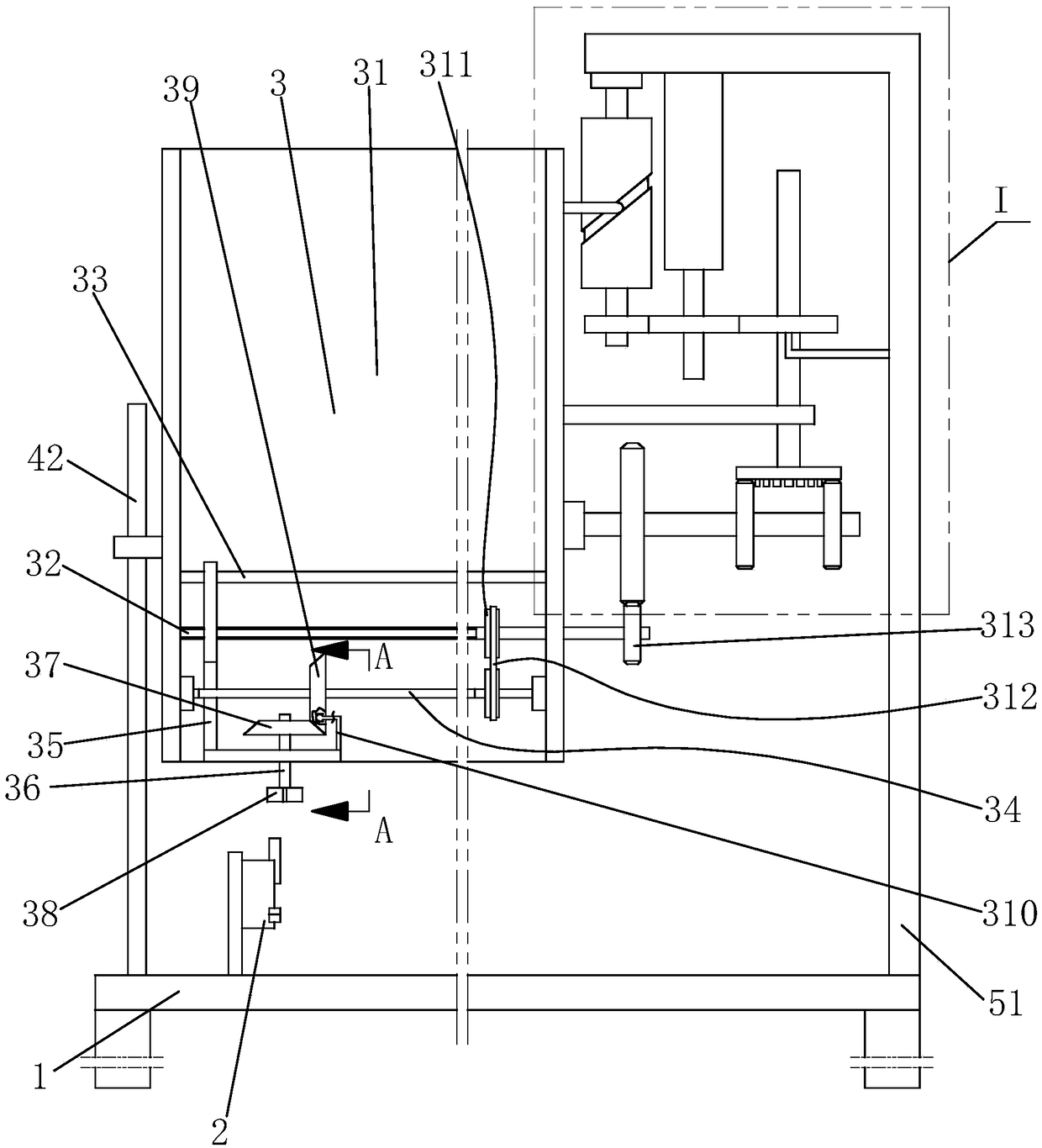

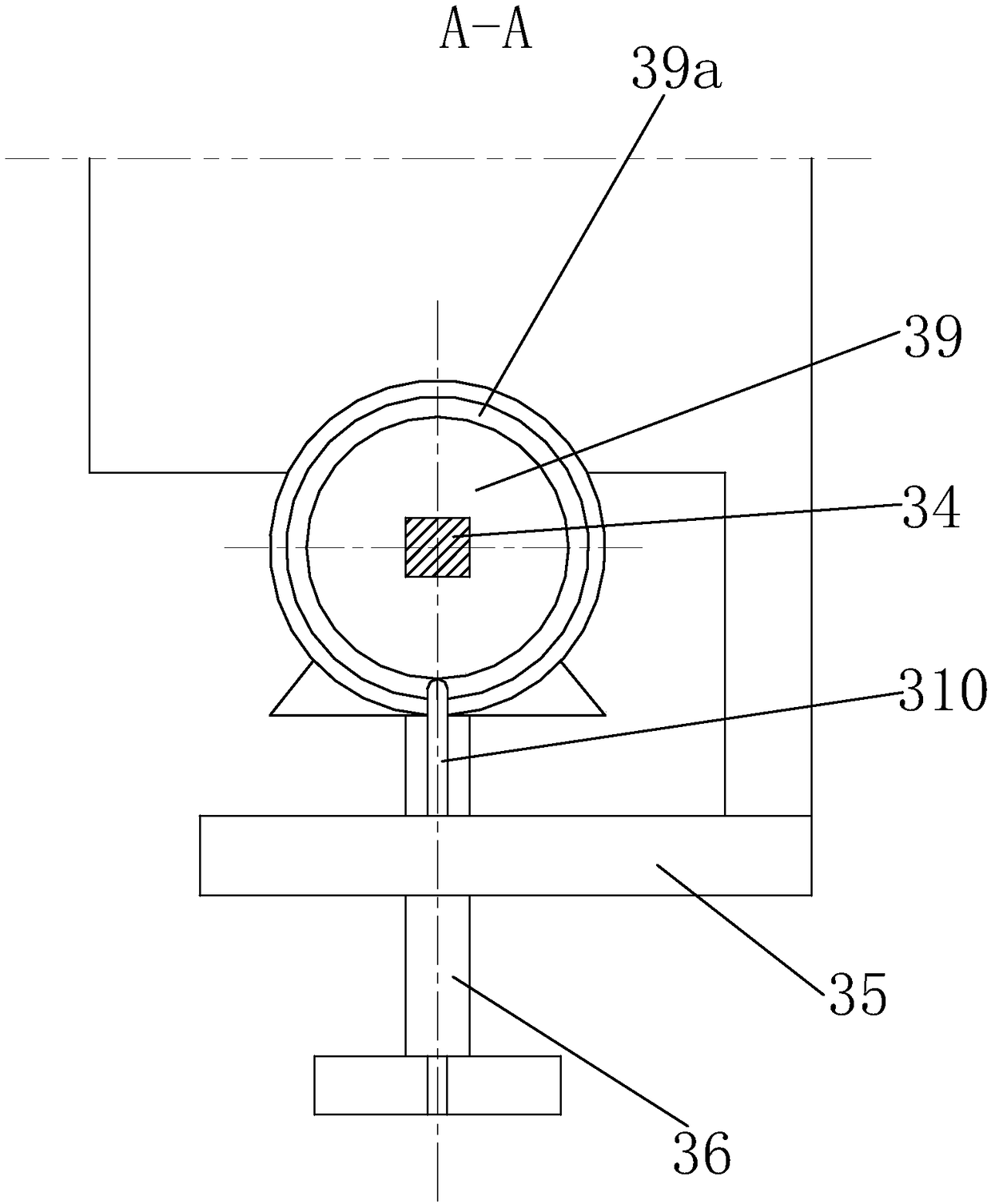

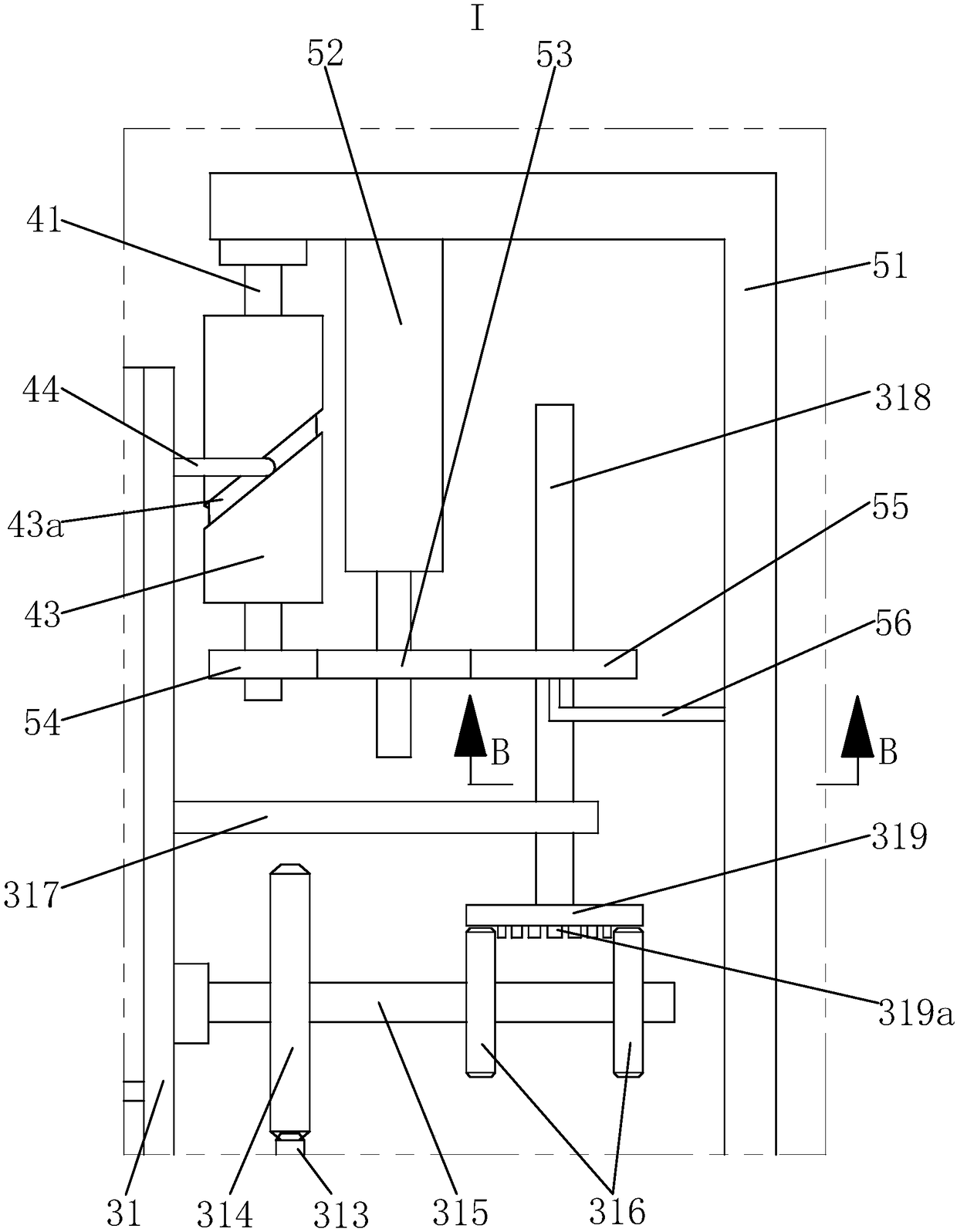

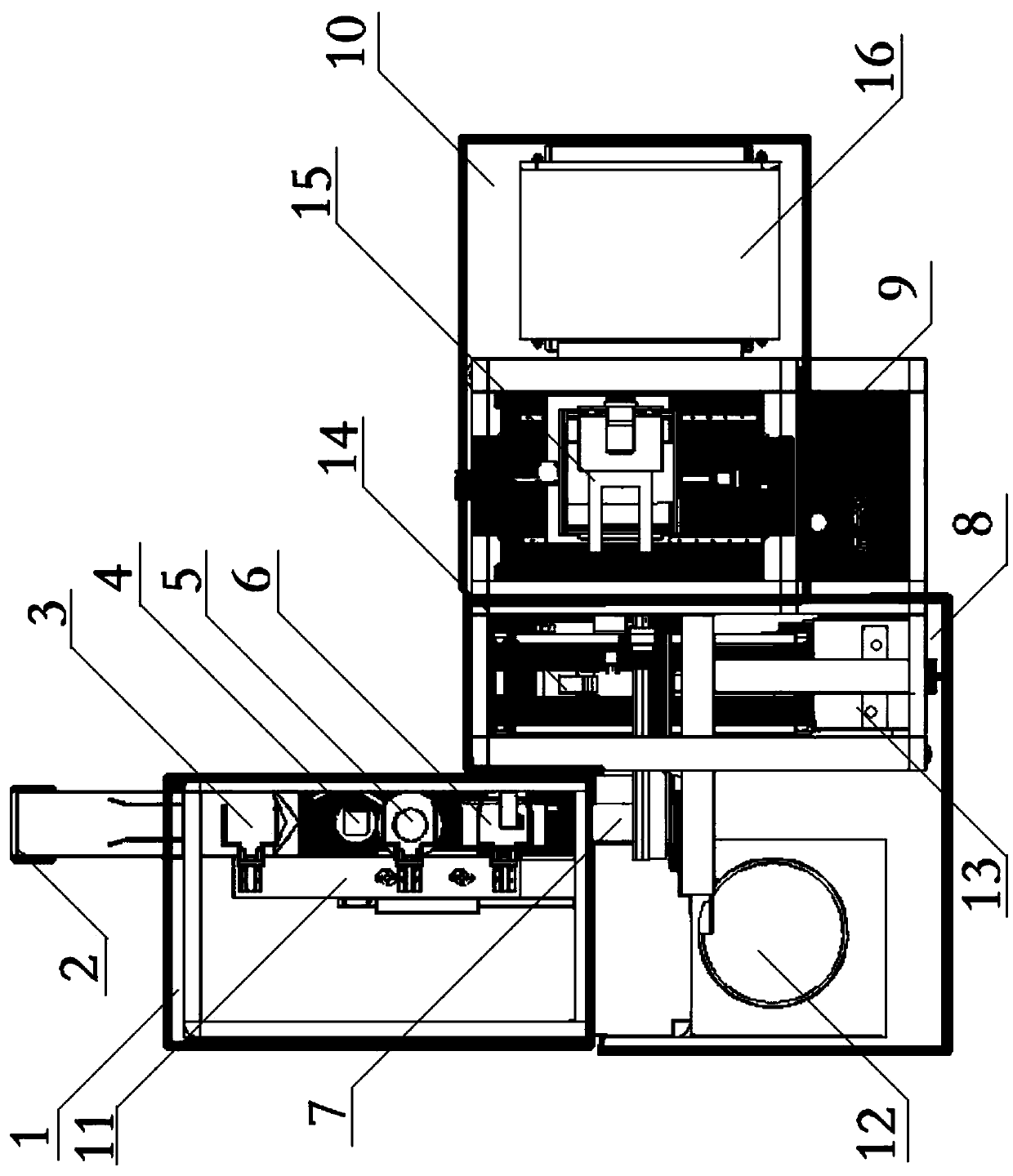

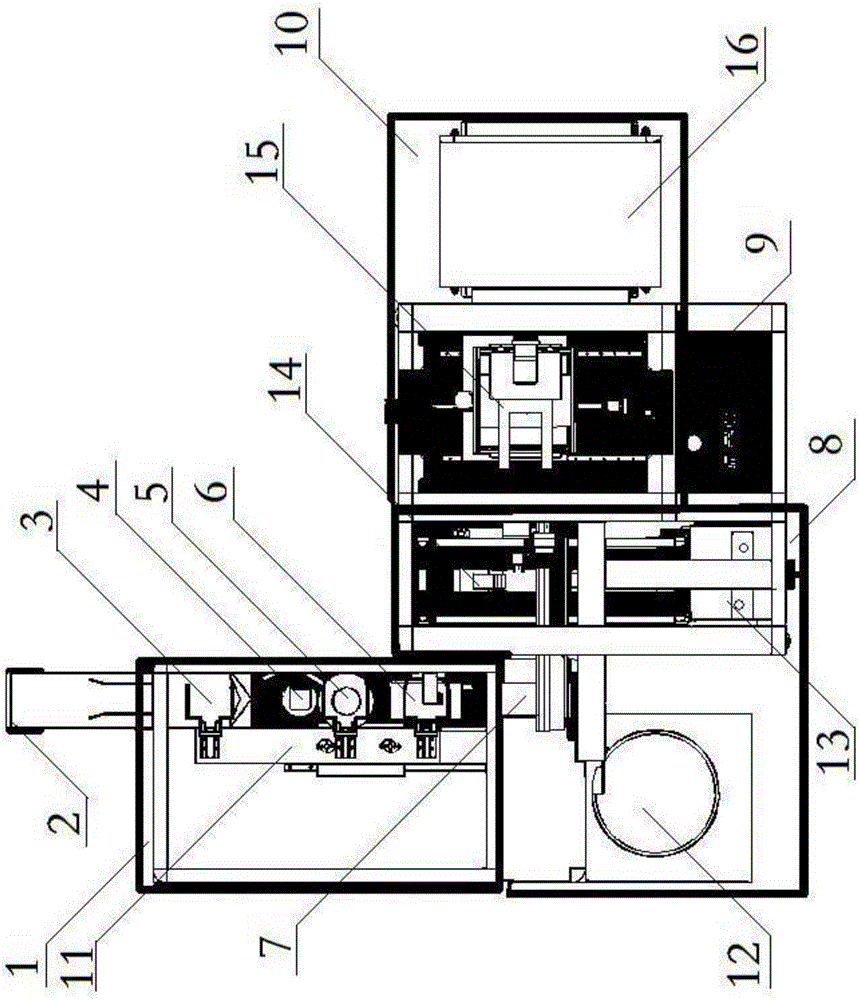

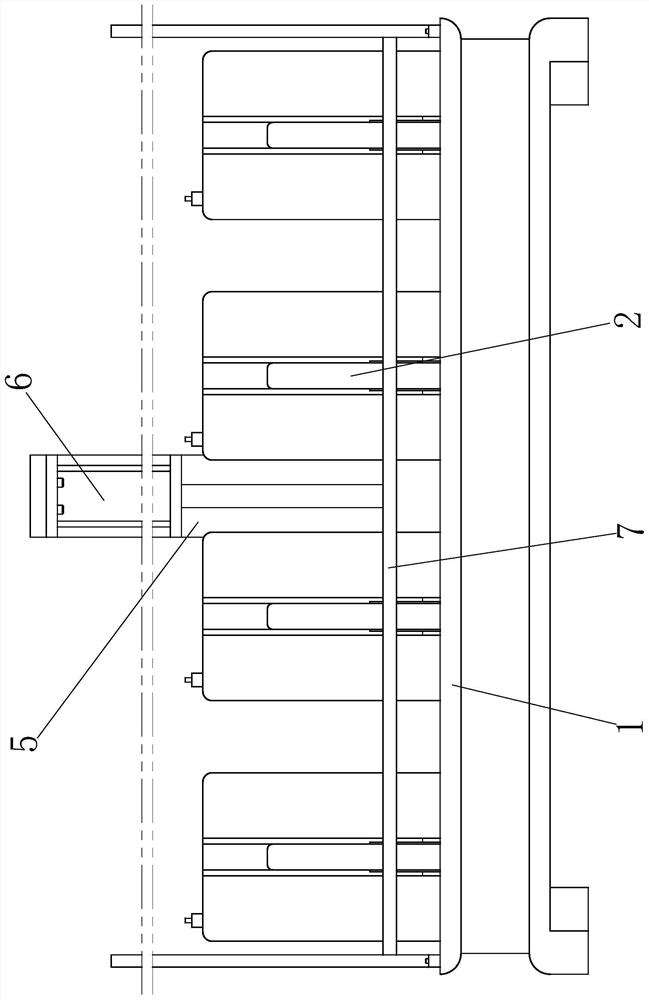

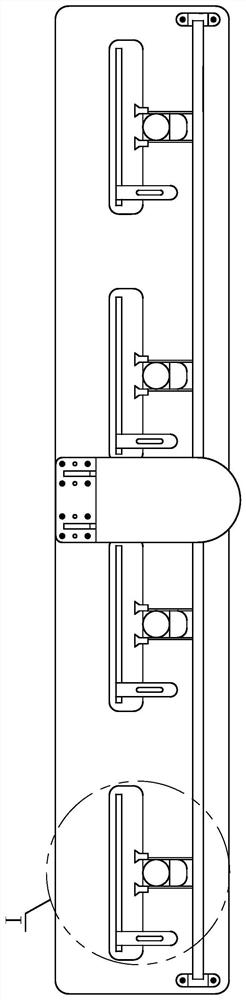

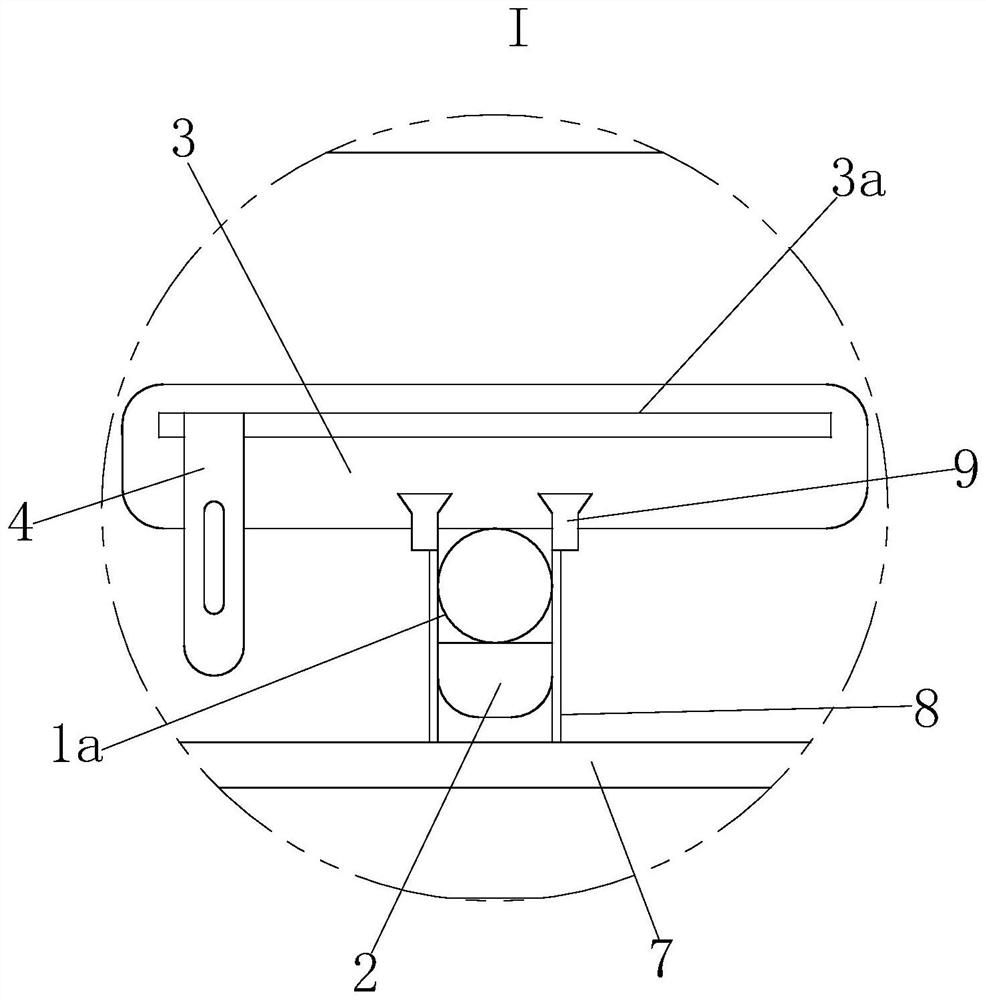

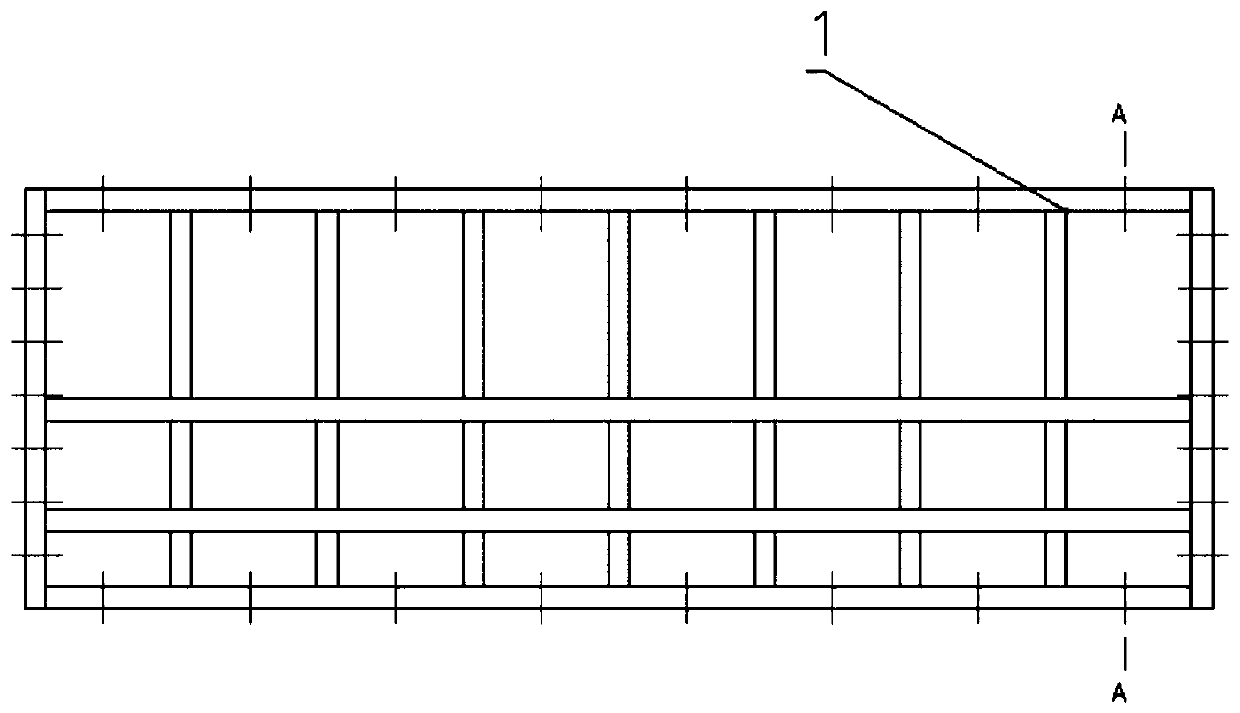

OCVB test machine

PendingCN107116038AReduce the amount of manual involvementReduce labor costsCell component detailsSortingTransfer mechanismAutomotive engineering

The invention discloses an OCVB test machine. The OCVB test machine comprises an IV test mechanism, an OCV test mechanism, a lug scraping and pressing mechanism and a lug cutting mechanism and further comprises a test pulling belt, a transferring mechanism arm and a discharging and sorting mechanism arm. The test pulling belt is used for conveying battery cells and sequentially flows through a code scanning mechanism, the OCV test mechanism, the lug scrapping and pressing mechanism and the lug cutting mechanism. The code scanning mechanism is used for scanning codes on the battery cells. The transferring mechanical arm puts the battery cells which are subjected to IV testing on the test pulling belt. A first code scanning device is arranged at the position of the OCV test mechanism, and a second code scanning device is arranged at the position of the discharging and sorting mechanical arm. The code scanning mechanism, the first code scanning device and the second code scanning device in the OCVB test machine bond the IV test information and the OCV test information of the battery cells with the codes of the battery cells. After lugs of the battery cells are cut, the discharging and sorting mechanical arm puts the qualified battery cells and the unqualified battery cells separately. The OCVB test machine can form intelligent assembly line work.

Owner:DONGGUAN ALI AUTOMATION CO LTD

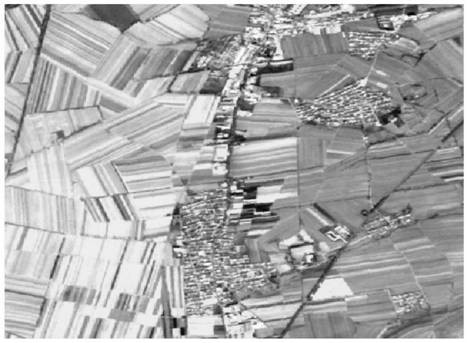

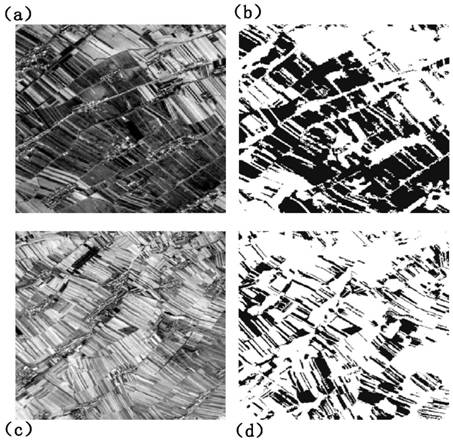

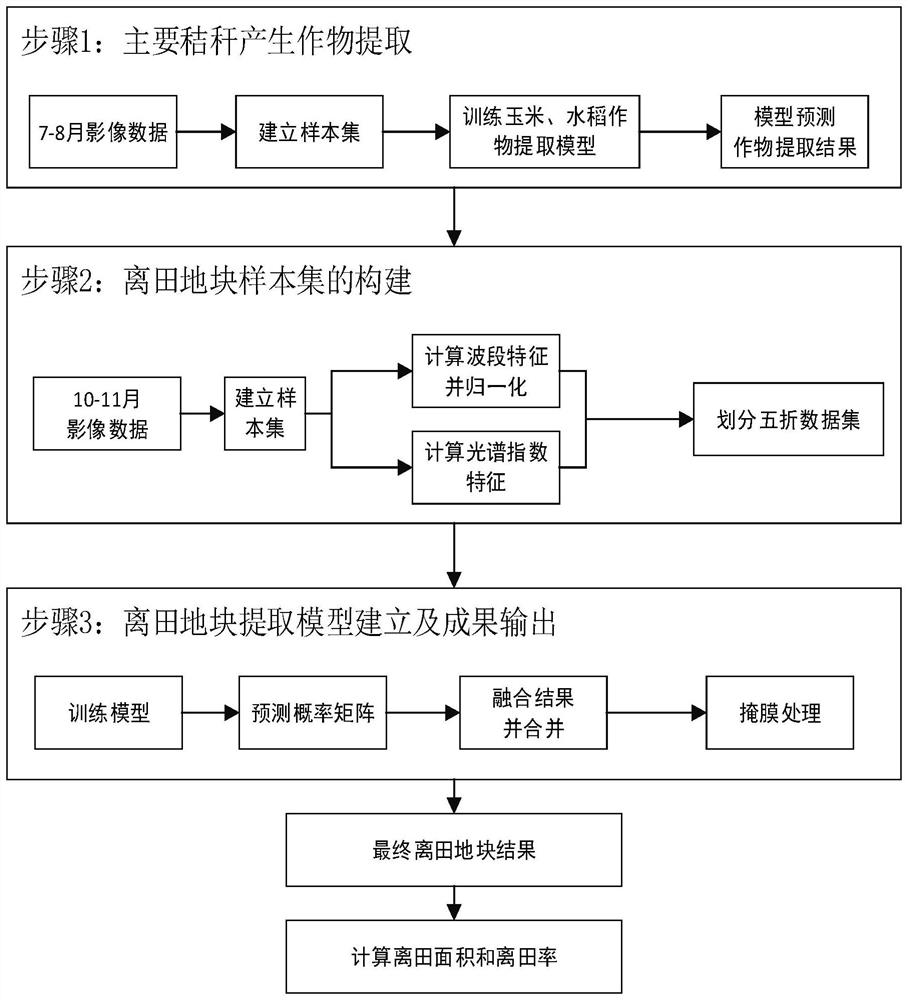

Machine learning multispectral remote sensing image crop straw out-of-field extraction method and system

PendingCN114359746ASolve the errorSupervise the progress of leaving the fieldScene recognitionSoil scienceMultispectral image

The invention discloses a multispectral remote sensing image crop straw off-field extraction method and system based on machine learning, and solves the problems that personal errors and measurement errors exist in the off-field area and progress of an existing straw off-field supervision mode, and accurate management and control cannot be realized on non-off-field area positioning. Comprising the following steps: S1, acquiring multispectral image data of a crop growth period, sketching and establishing a polygon sample set according to crop spectral information, establishing a crop classification model, and predicting the established crop classification model to obtain a crop distribution result; s2, acquiring multispectral image data after a crop harvest period, sketching polygonal samples of corresponding categories, and performing sampling treatment to obtain a polygonal sample set of an out-of-field plot; and S3, dividing the polygonal sample set of the out-of-field plot by utilizing five-fold division, training the obtained five groups of training sets-verification sets to obtain five base models, predicting the image data by using the base models, and determining the out-of-field plot through probability mean value fusion of prediction results.

Owner:CHANGGUANG SATELLITE TECH CO LTD

A urinal for automatically processing excreta

ActiveCN109106540AHigh degree of automationReduce the amount of manual involvementNursing urinalsMedical transportEngineeringToilet

The invention discloses a urinal for automatically processing excreta, which comprises a urinal main body and a support for supporting the urinal main body, and a rack positioned below the urinal body. The frame is provided with two opposite rails and a plurality of sliding rods which are respectively slidably connected to a rail, and each of the sliding rods is provided with a fixing member for fixing the bag, and one end of the rail is provided with a first driving for driving the sliding bar to slide. The device further has a first pushing block capable of unidirectional passage of the sliding bar under the main body of the toilet, and a second driving device for driving the driving block to move along the longitudinal direction of the guiding rail, and the sealing device is further provided with a sealing under the other end of the guiding rail. The device and the auxiliary sealing device for auxiliary sealing action utilize the guide rail and the sliding rod structure, and the device can realize the functions of automatic bag feeding and automatic sealing, high degree of automation and greatly saving manpower, and the invention is used in the field of nursing equipment.

Owner:GUANGZHOU HUANSI INSTR TECH CO LTD

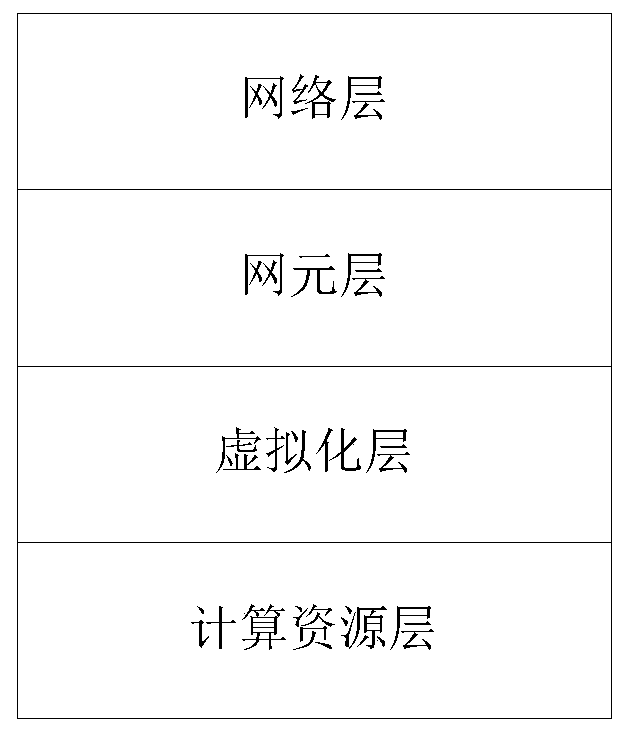

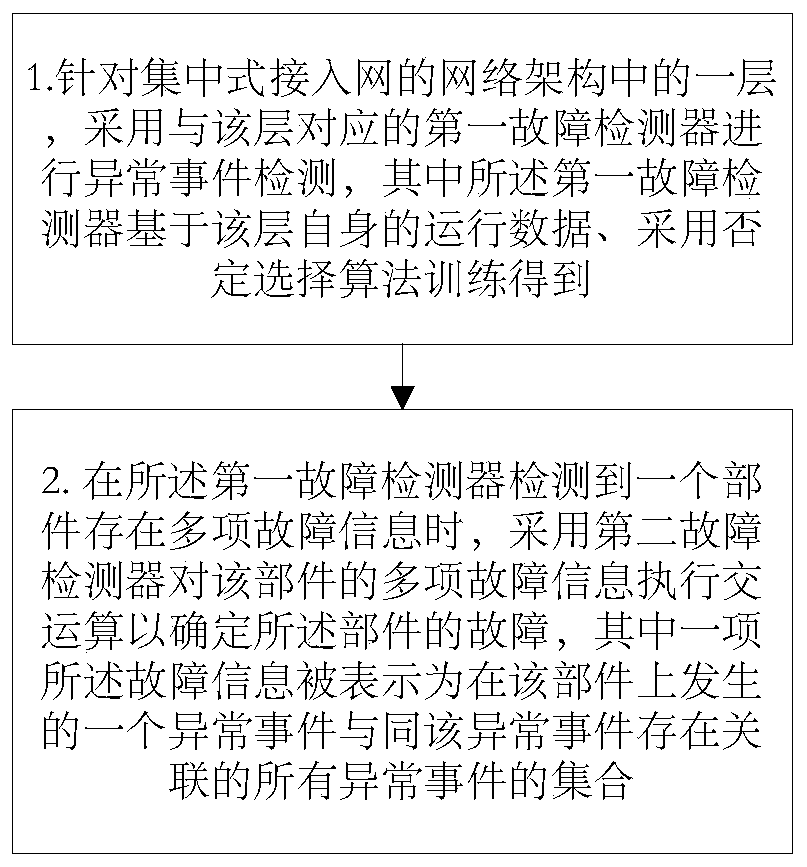

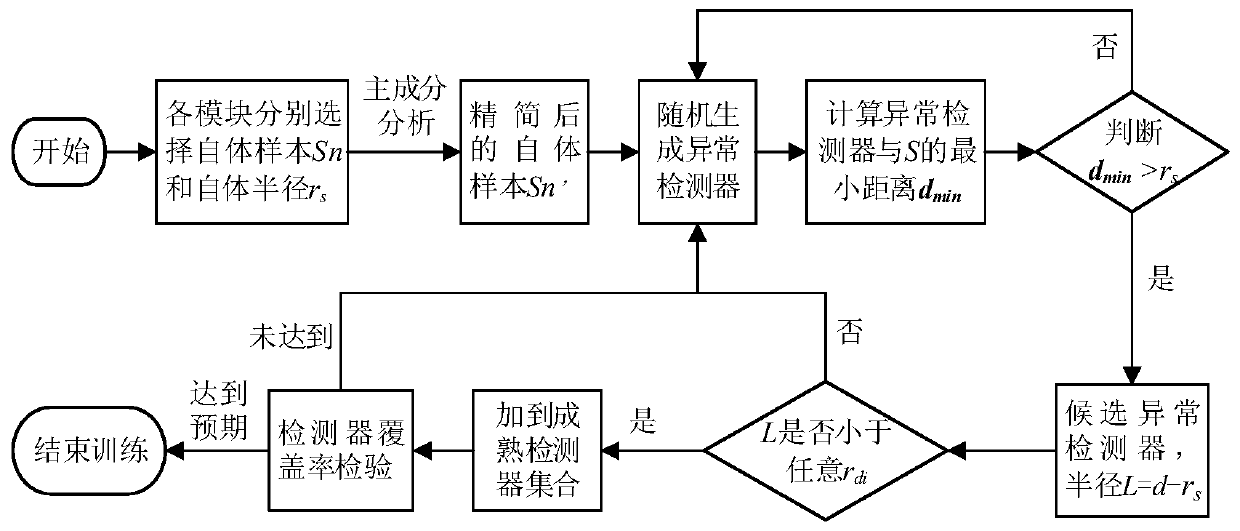

Fault detection method for centralized access network

PendingCN110225540AReduce the amount of manual involvementHigh degree of automationData switching networksWireless communicationNetwork architectureReal-time computing

A method for executing anomaly detection on a centralized access network comprises the steps that (1) for one layer in a network architecture of the centralized access network, a first fault detectorcorresponding to the layer is adopted for abnormal event detection, and the first fault detector is obtained through training by adopting a negative selection algorithm based on operation data of thelayer; (2) when the first fault detector detects that one component has multiple pieces of fault information, the first fault detector detects that the component has multiple pieces of fault information; a second fault detector is employed to perform an intersection operation on a plurality of pieces of fault information of the component to determine a fault of the component, wherein one of the pieces of fault information is represented as a set of abnormal events occurring on the component and all abnormal events associated with the abnormal event.

Owner:北京中科晶上科技股份有限公司

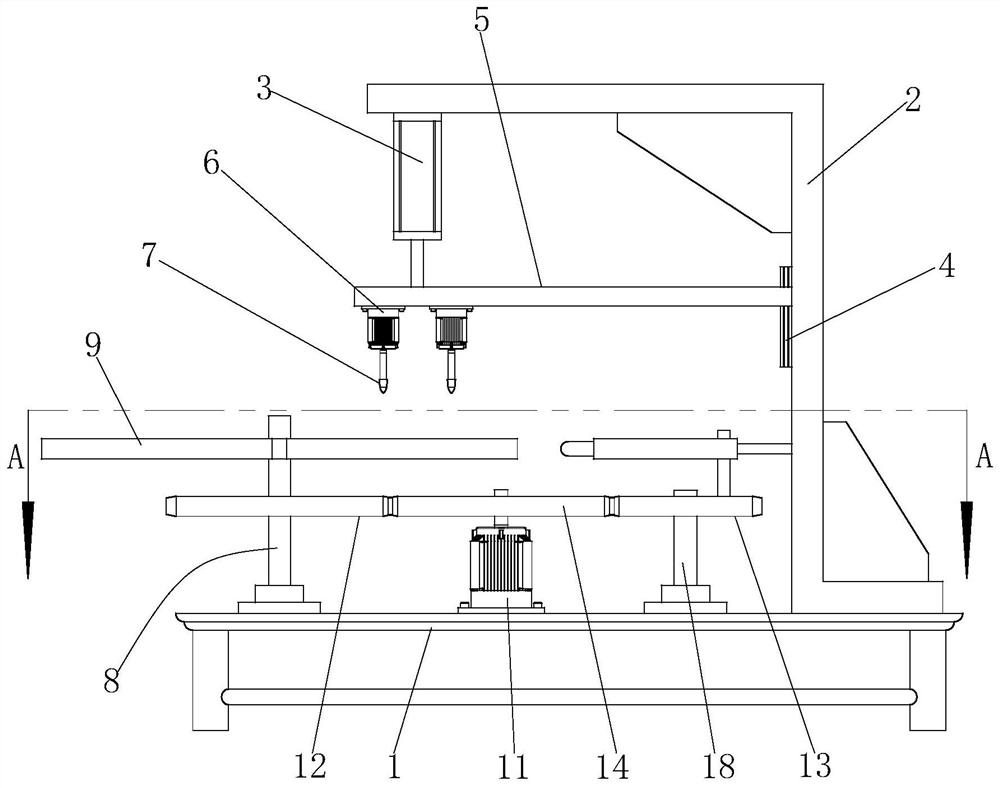

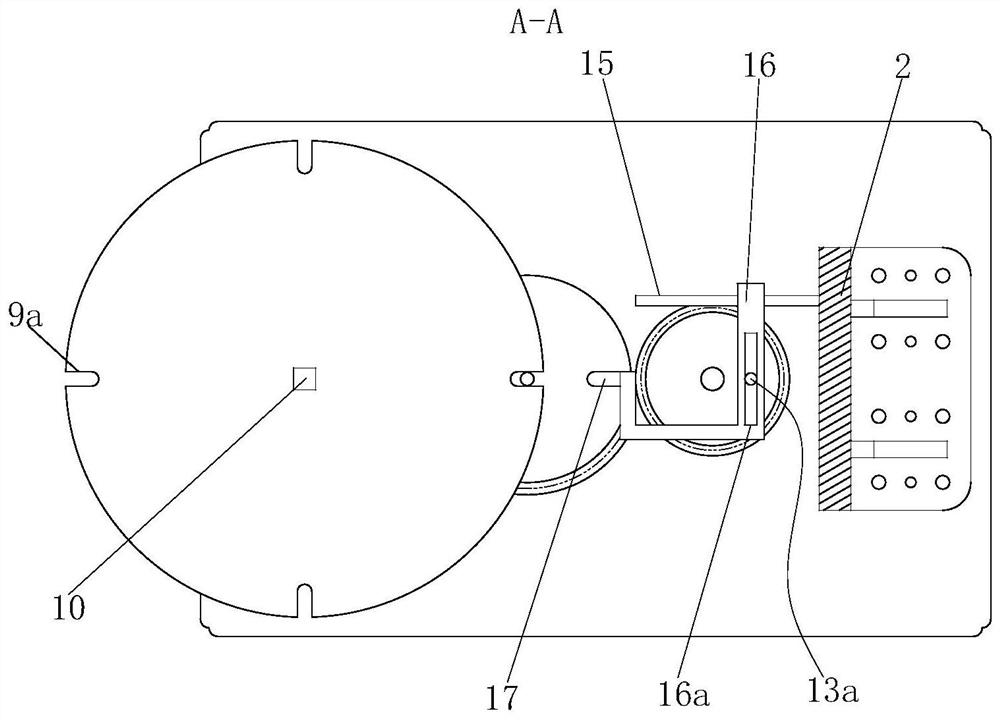

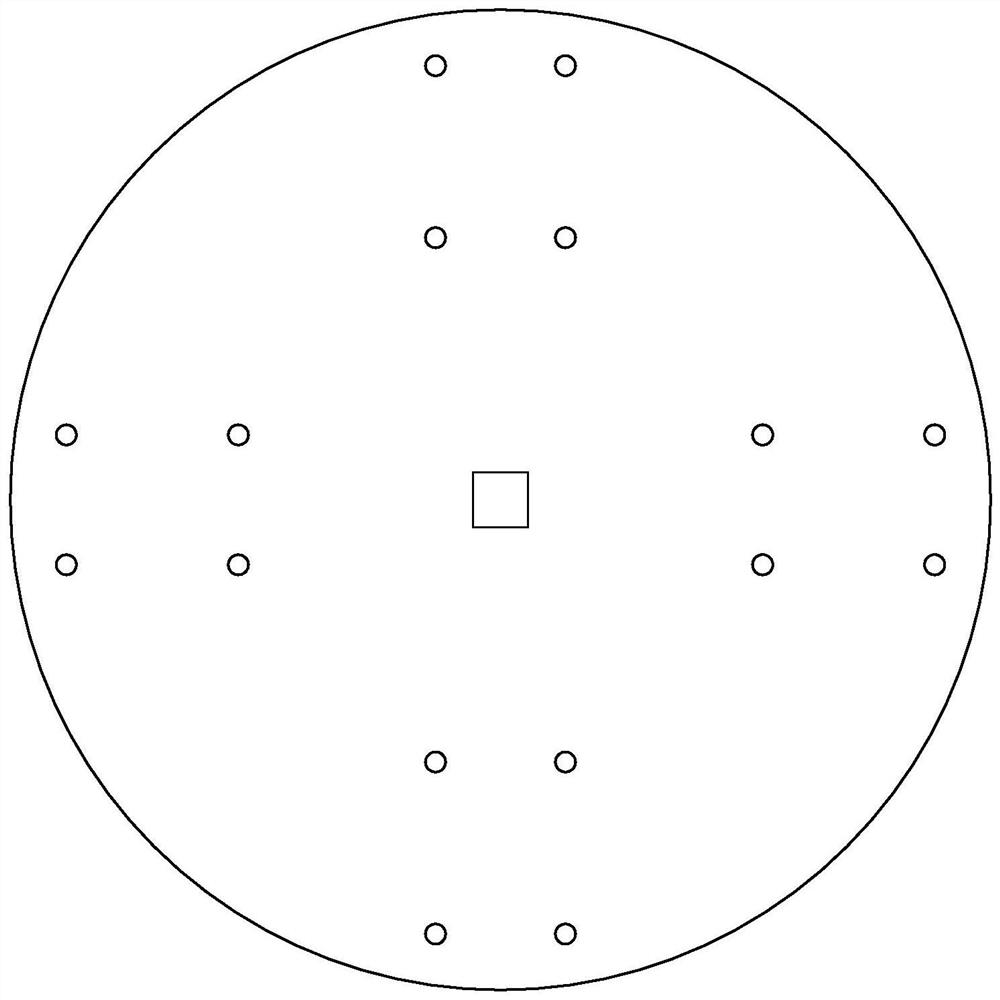

Drilling machining equipment for disc parts

InactiveCN112091260AAchieve lockingConvenient for automatic grindingLarge fixed membersBoring/drilling componentsMachiningWorkbench

The invention relates to drilling machining equipment for disc parts. The drilling machining equipment comprises a workbench and a hanging bracket fixedly installed on the workbench. A drilling control assembly is mounted on the hanging bracket. A main mandrel is installed on the workbench through a bearing seat, a supporting table is welded to the upper end of the main mandrel, and an installation shaft is arranged at the upper end of the supporting table. The main mandrel is further connected with a positioning and rotating control assembly. The drilling machining equipment is high in automation degree, on the basis of a drilling function, the supporting table can be controlled to rotate, sliding of plug pins is controlled to lock the supporting table, therefore automatic grinding machining can be conveniently conducted on the four edge faces of a regular rectangular pyramid part, the manual participation amount in the whole process is small, and operation is convenient and fast.

Owner:WUHU KAIDE MACHINERY MFG

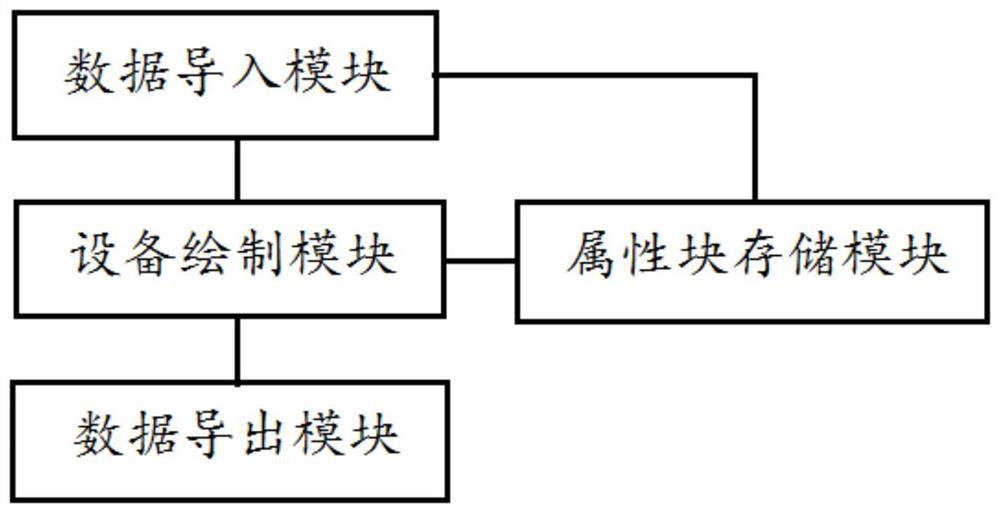

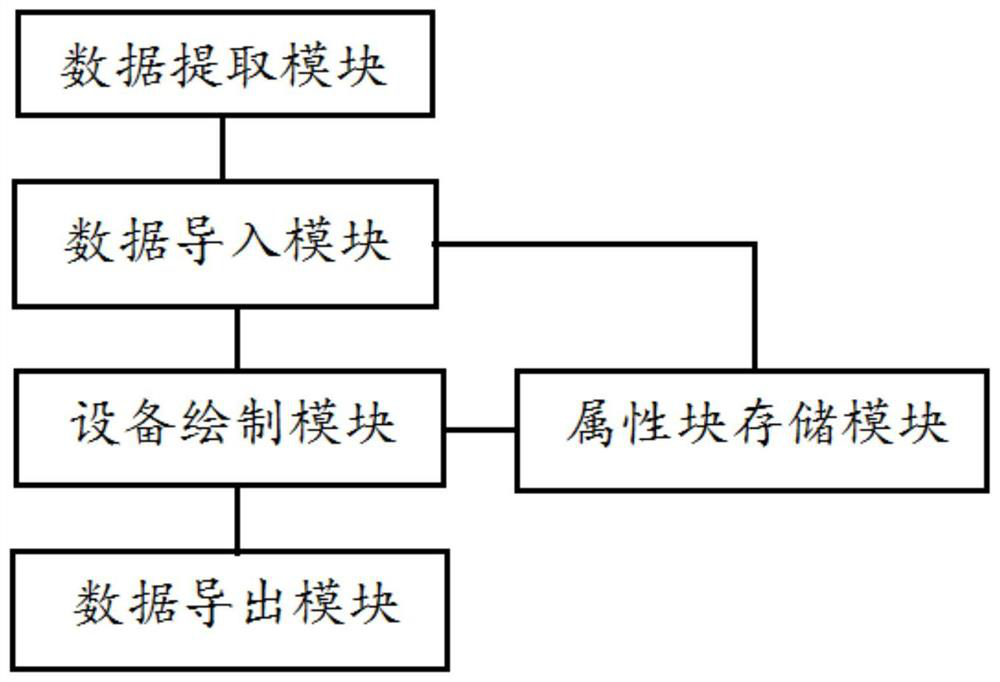

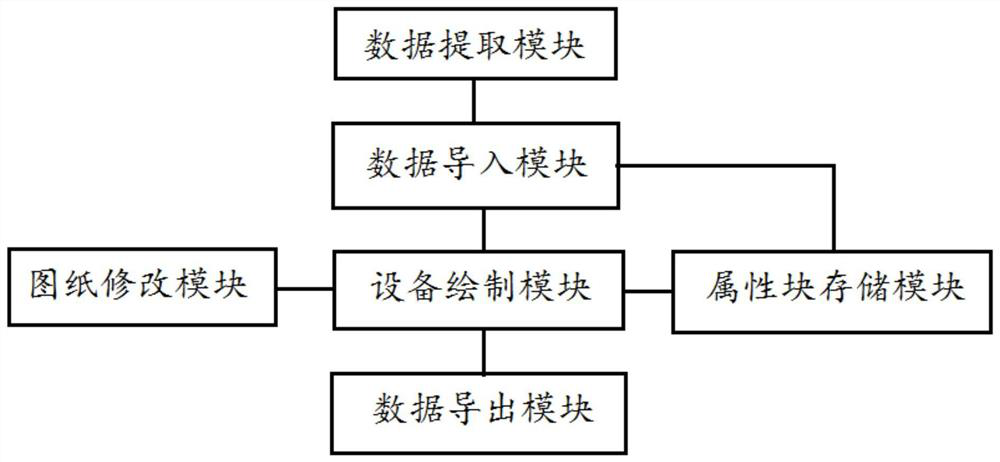

Equipment drawing system based on signal system

InactiveCN113192159AImprove accuracyDraw granularity is smallNatural language data processingEditing/combining figures or textSoftware engineeringData needs

The invention belongs to the field of intelligent software, and particularly relates to an equipment drawing system based on a signal system, which comprises: an attribute block storage module used for storing related data of drawn equipment; the data importing module that is used for importing basic data or importing related data of the equipment in the attribute block storage module; the equipment drawing module that is used for completing drawing of the current equipment according to the basic data and storing related data of the drawn equipment in the attribute block storage module, or completing drawing of the current equipment according to the related data of the equipment in the attribute block storage module; and the data export module that is used for exporting the system data and the drawing data of the drawn equipment. Related data of the drawn equipment are stored in the attribute block storage module, only basic data need to be imported once during starting, and system deployment is extremely simple.

Owner:浙江众合科技股份有限公司

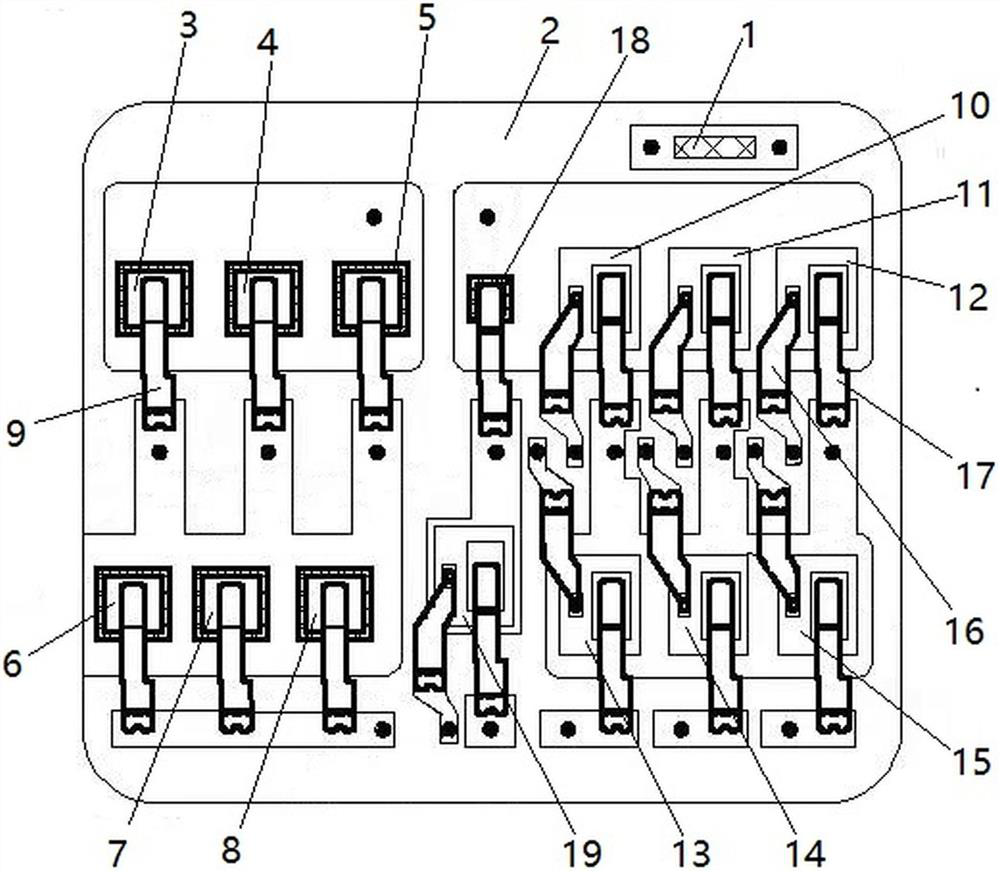

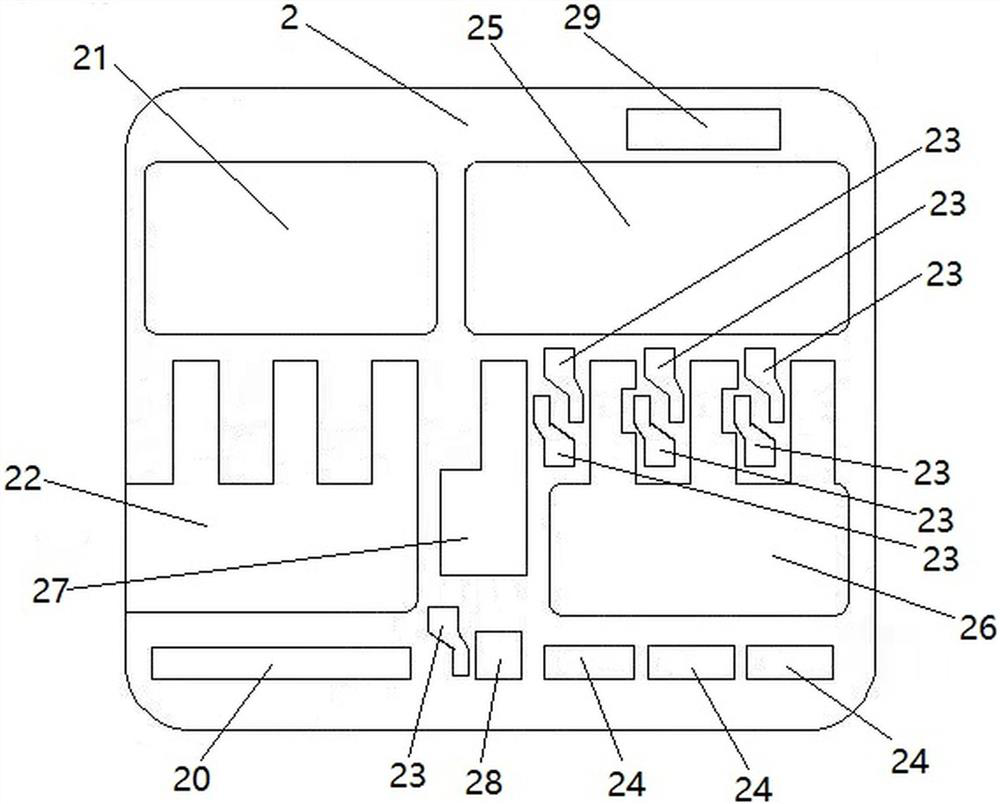

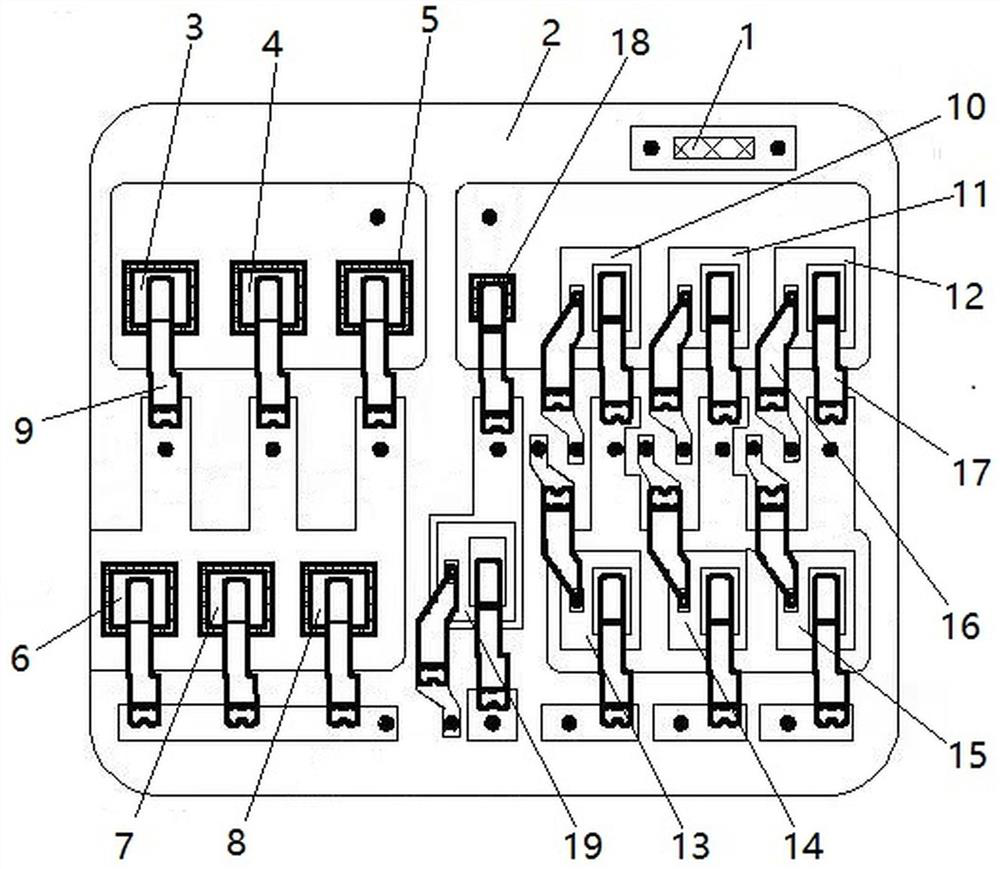

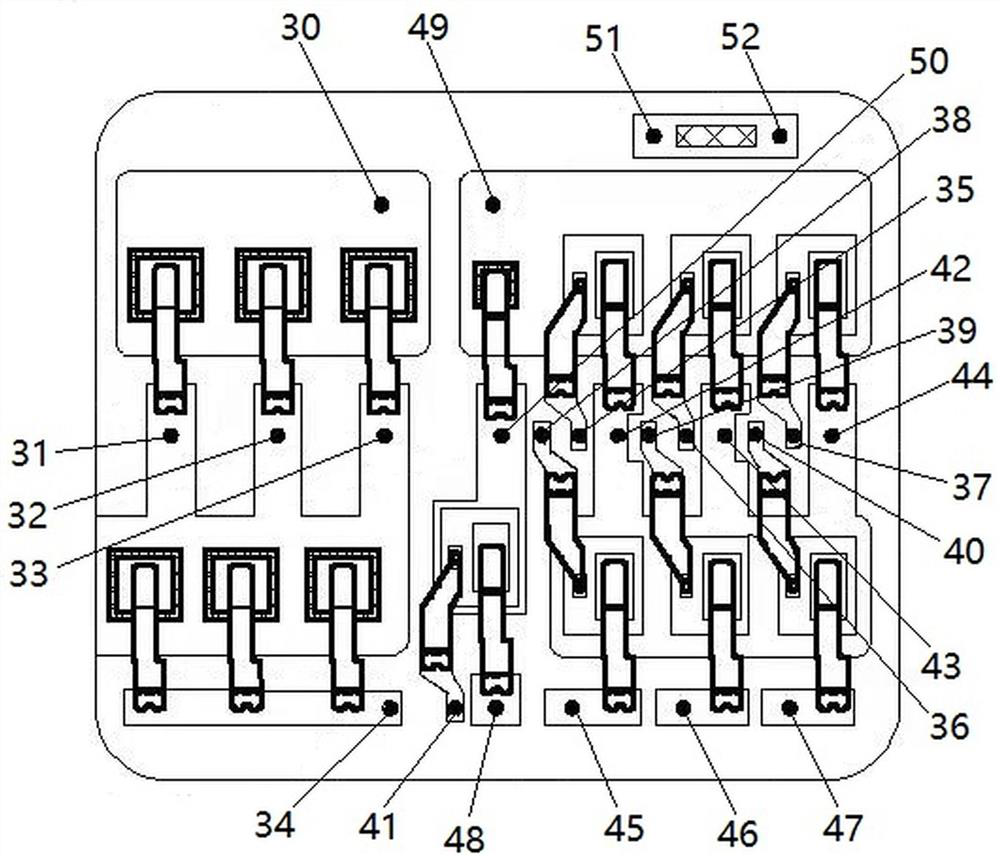

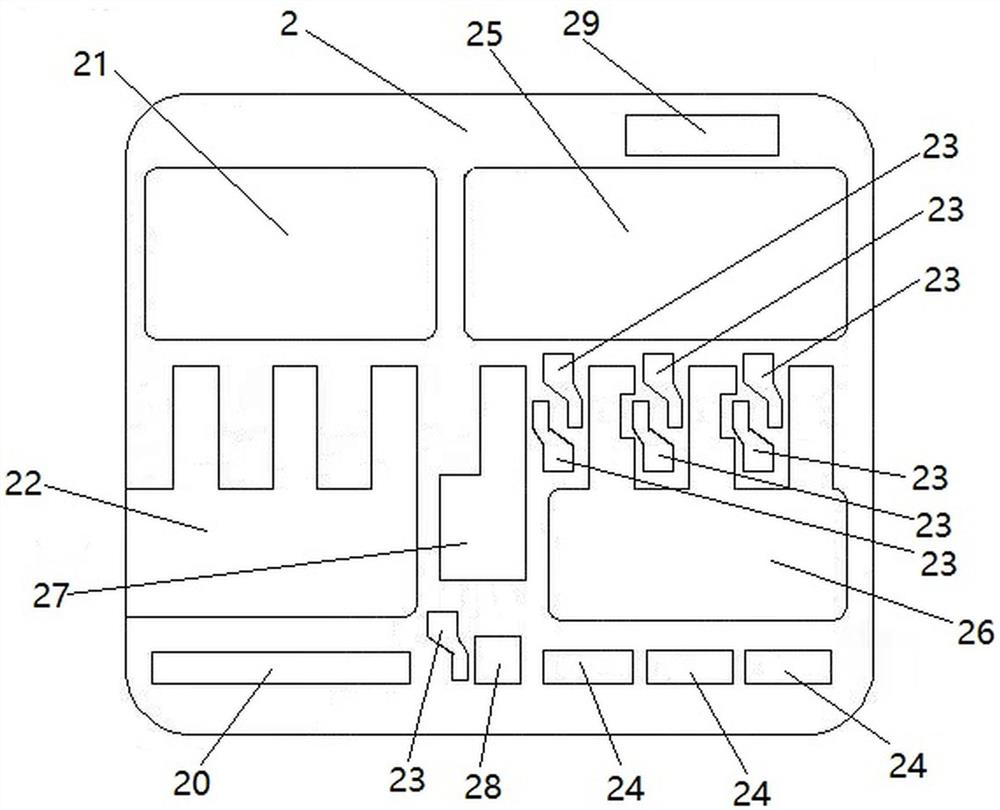

PIM device and manufacturing method thereof

ActiveCN113556026AGood thermal cycleShape stableAC motor controlSemiconductor/solid-state device detailsPhysicsEngineering

The invention relates to the technical field of semiconductor devices, in particular to a PIM device and a manufacturing method thereof, and the PIM device comprises a copper-clad ceramic substrate, and a three-phase rectification unit, a three-phase inversion unit, a braking unit and a temperature control detection NTC device which are arranged on the copper-clad ceramic substrate; the three-phase rectification unit comprises six diode chips arranged on the copper-clad ceramic substrate and clip copper sheets corresponding to the six diode chips one by one; the three-phase inversion unit comprises six IGBT chips, six clip emitter copper sheets in one-to-one correspondence with the six IGBT chips, and six clip control electrode copper sheets in one-to-one correspondence with the six IGBT chips. The braking unit comprises a diode chip VII, an IGBT chip VII, a clip copper sheet, a clip emitter copper sheet and a clip control electrode copper sheet. According to the technical scheme, the PIM device is small and exquisite in structure and convenient to use, when the PIM device is applied to a related circuit, the circuit structure can be simplified, the PIM device is stable in performance based on the clip technology adopted by the PIM device, and the circuit using the PIM device is further safe and reliable.

Owner:乐山希尔电子股份有限公司 +1

Square aluminum pipe milling equipment

InactiveCN108838448AHigh degree of automationEasy to control and useFeeding apparatusMilling equipment detailsMilling cutterLong axis

The invention relates to square aluminum pipe milling equipment which comprises a workbench. A three-jaw chuck is installed in the middle of the upper end of a bottom plate in a rotary mode, a transverse milling device is arranged over the three-jaw chuck and comprises a U-shaped frame, a square shaft and a lead screw installed on the U-shaped frame through a bearing, feeding assemblies are arranged on the left side and the right on the workbench, each feeding assembly comprises a long shaft and a guide rod for achieving vertical sliding installation of the U-shaped frame, and a reversing driving device connected with each long shaft and the square shaft is arranged between the corresponding long shaft and the square shaft. The automation degree is high, and a milling cutter can be effectively controlled to carry out horizontal transverse milling and downward feeding circulation alternately. The four large faces of a square aluminum pipe can be automatically milled in sequence, the whole process is convenient to control and use, and the human intervention degree is low.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

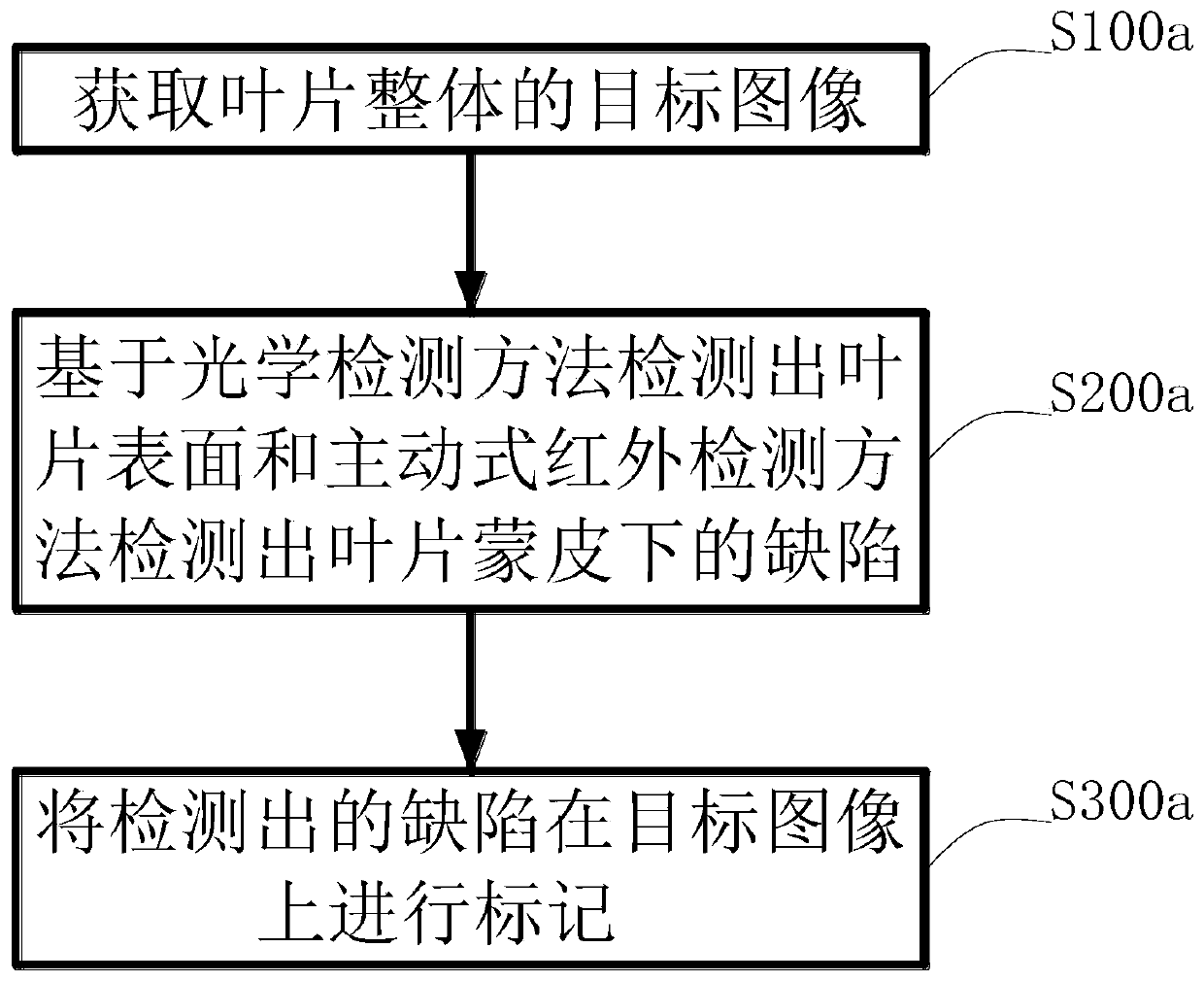

Method for detecting defect of blade, and method for maintaining defect of blade

ActiveCN110174413AImprove detection accuracyReduce mistakesOptically investigating flaws/contaminationEngineeringActive infrared

The invention relates to a method for detecting a defect of a blade, which comprises the following steps: S100a, acquiring a target image of the whole blade; S200a, detecting a defect of the surface of the blade based on an optical detection method and detecting a defect under the skin of the blade by an active infrared detection method; and S300a, marking the detected defects on the target image.The method of the invention has the advantages that: the defects of the surface of the blade and the detects under the skin of the blade can be detected through optical and infrared detection, and the defects are marked in the whole image of the blade, so that the condition of the blade can be checked in the later period conveniently; in addition, when the blade is detected subsequently, the marked defects can be focused; and compared with manual detection, the method has high detection precision and small error, and can detect the internal defects which cannot be observed by naked eyes.

Owner:中新红外科技(武汉)有限公司

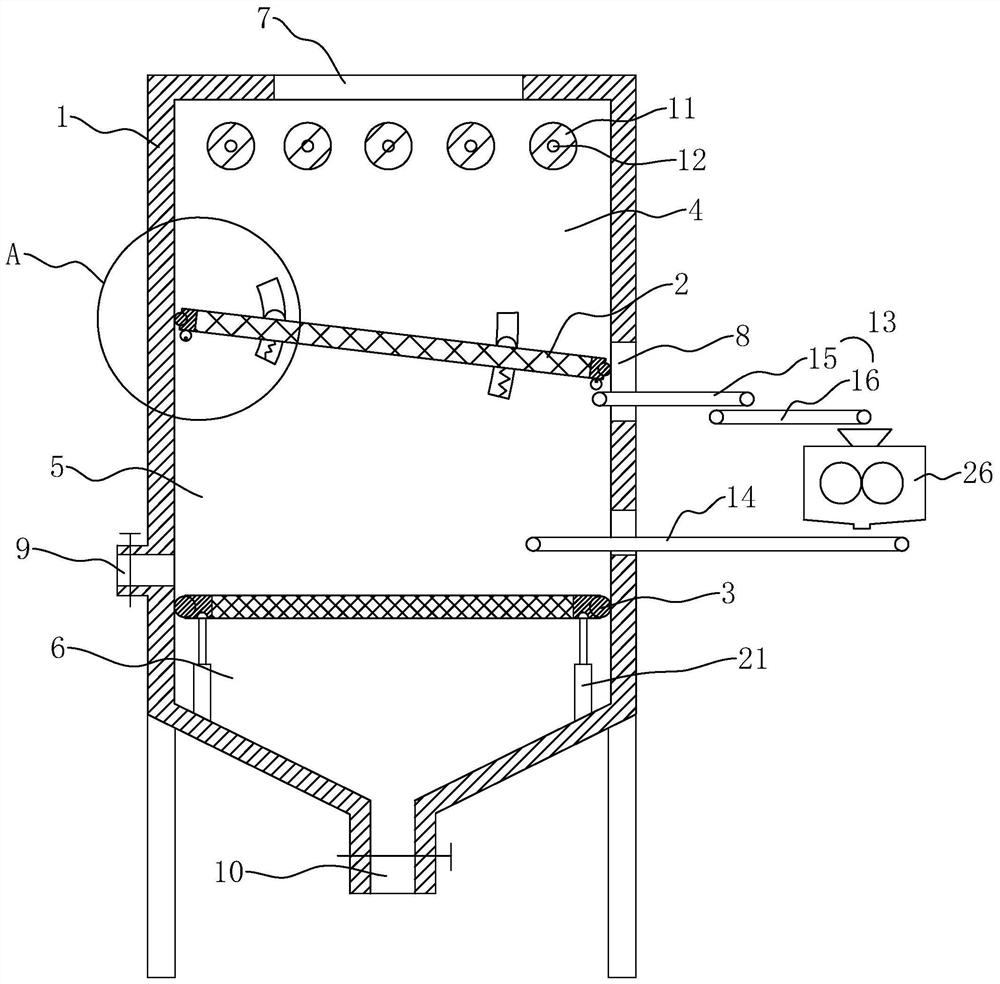

PP decorative film casting machine

The invention relates to the technical field of casting machines, in particular to a PP decorative film casting machine. The PP decorative film casting machine comprises a feeding platform frame, a drying mixer, a screw feeder, a variable-frequency drive motor, an extruder base, a rim charge recovering and forced feeding device, a PP raw material plasticizing screw charging barrel, an oil pressurefilter screen replacing device, a hanger type special die head, a 90-degree elbow device, a complete machine console, a film forming table device, an adjustable auxiliary cooling roller, a forming steel roller, a forming rubber roller, a secondary cooling traction device, a water chilling unit and a water die temperature unit, the feeding platform frame is fixedly installed on the right side of the drying mixer, and the screw feeder is fixedly installed on the left side of the drying mixer. According to the PP decorative film casting machine, the purposes of reducing energy consumption, improving the automatic control process, reducing the production cost and improving the product quality are achieved, the automatic feeding process of raw materials can be more stable, the transparency, gloss and thickness uniformity of the film are improved, and the effect of obviously reducing the labor cost is achieved.

Owner:中山凤纪科技有限公司

Construction waste crushing and screening machine

PendingCN113231174AEasy to follow upEasy to operateGrain treatmentsProcess engineeringMaterial transport

The invention relates to a construction waste crushing and screening machine which comprises a screening module, a conveying module and a crushing module. The screening module comprises a screening box, and a first screening plate and a second screening plate are sequentially arranged in the screening box from top to bottom; and the first screening plate and the second screening plate divide the screening box into a first storage cavity, a second storage cavity and a third storage cavity which are arranged from top to bottom. The conveying module comprises a first conveying unit used for conveying materials in the first material storage cavity to the crushing module and a second conveying unit used for conveying materials at a discharging port of the crushing module to the second material storage cavity, and a magnetic attraction mechanism used for attracting metal is arranged in the first material storage cavity. Classified materials are discharged to different places, so that follow-up treatment is facilitated. Besides, the construction waste in the first material storage cavity is crushed in the crushing module again, and then enters the screening box for screening for the second time, so that the transportation of the waste is facilitated, and the subsequent treatment is better facilitated.

Owner:温州亿润建设有限公司

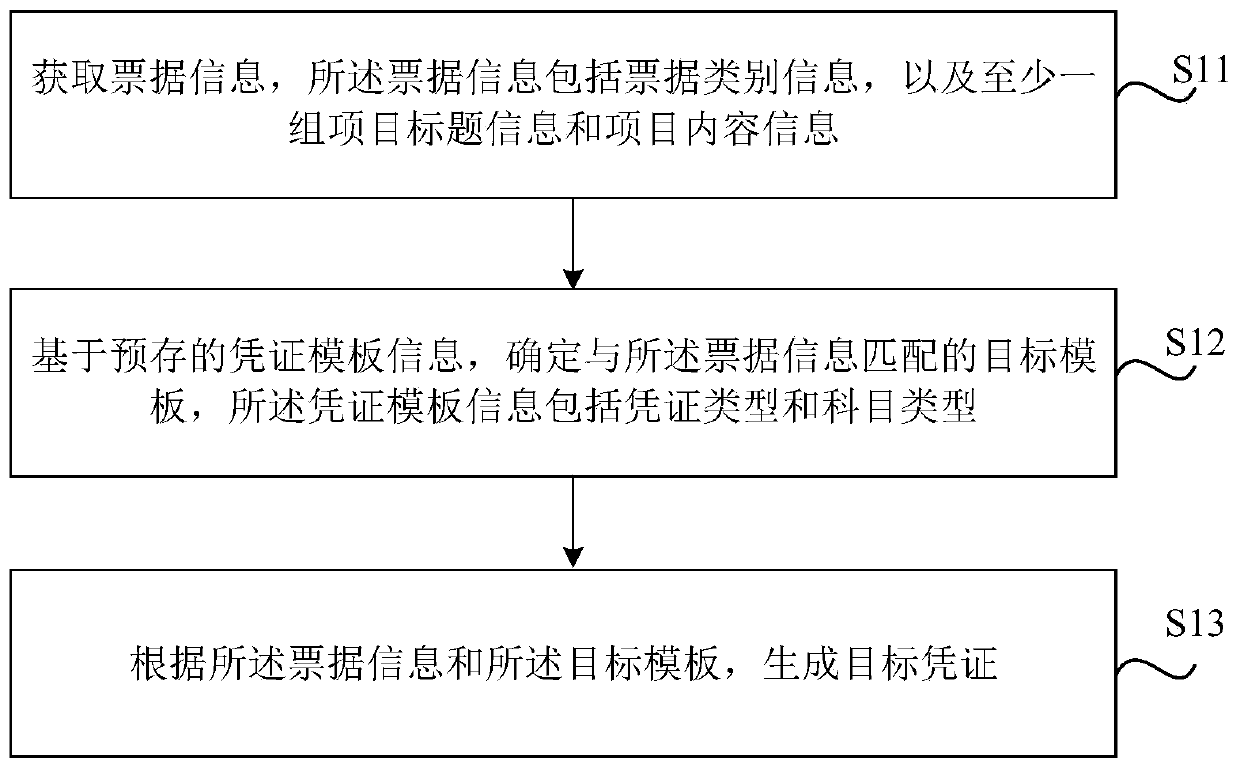

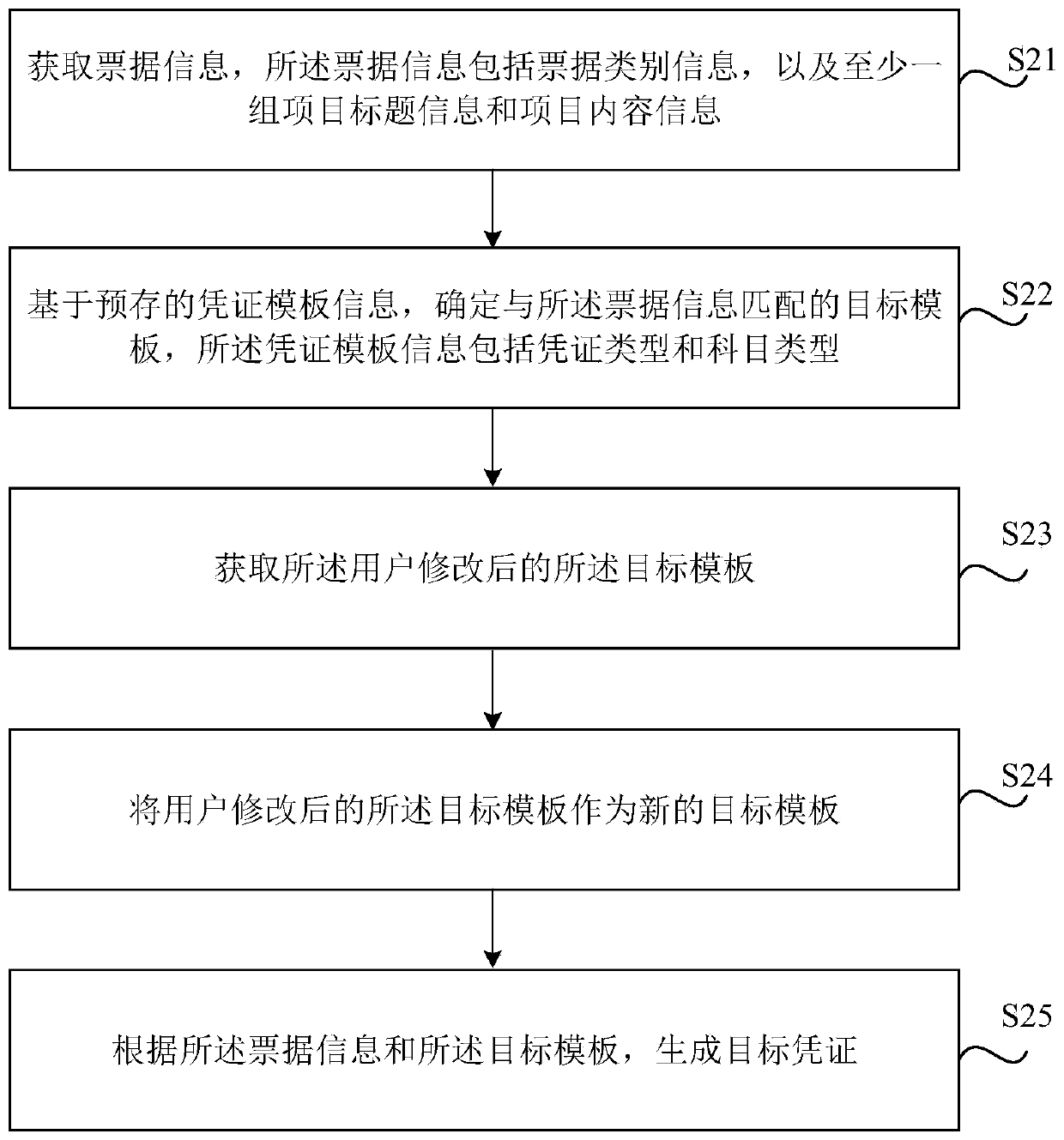

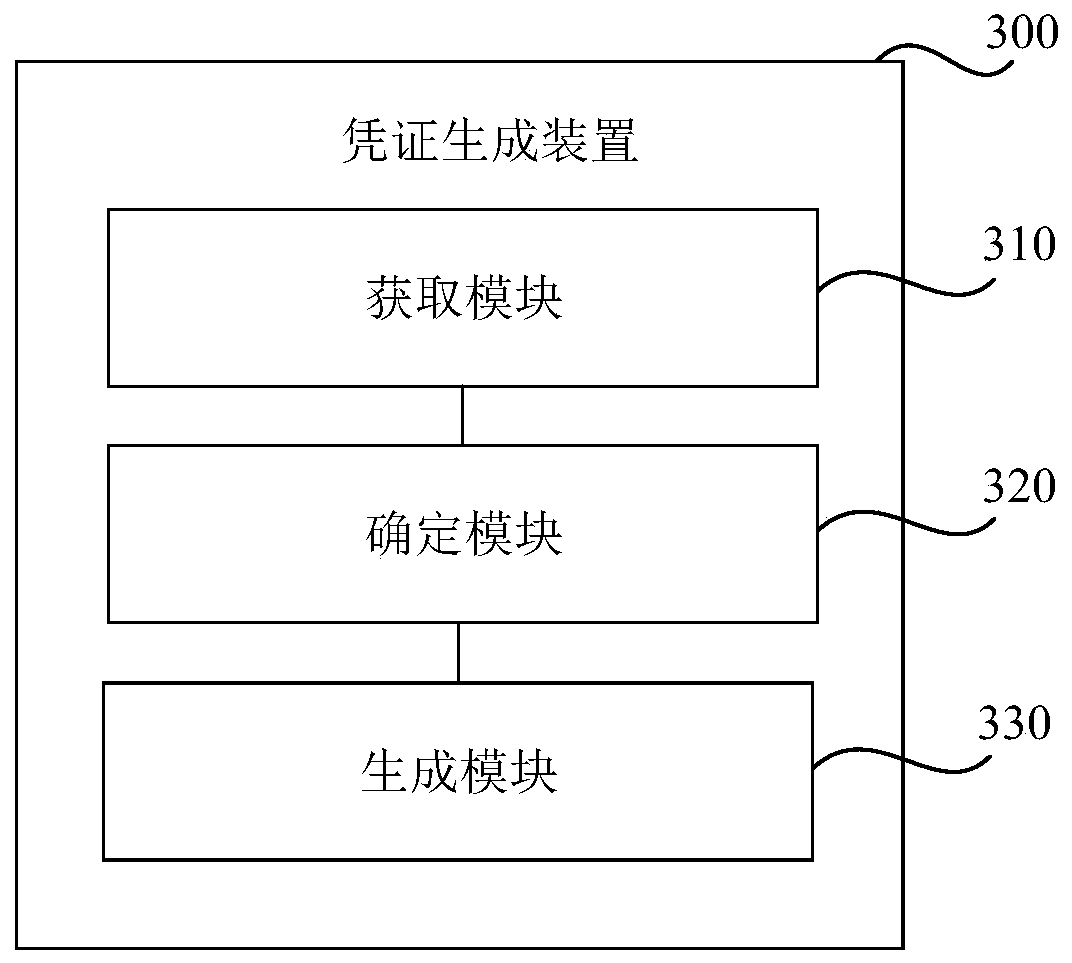

Voucher generation method and device, storage medium and electronic equipment

PendingCN111210328AImprove production efficiencyReduce the amount of manual involvementFinanceCharacter and pattern recognitionData miningOperations research

The invention relates to a voucher generation method and device, a storage medium and electronic equipment, and the method comprises the steps: obtaining bill information which comprises bill type information and at least one group of project title information and project content information; determining a target template matched with the bill information based on pre-stored voucher template information, the voucher template information comprising a voucher type and a subject type; and generating a target certificate according to the bill information and the target template.

Owner:AEROSPACE INFORMATION

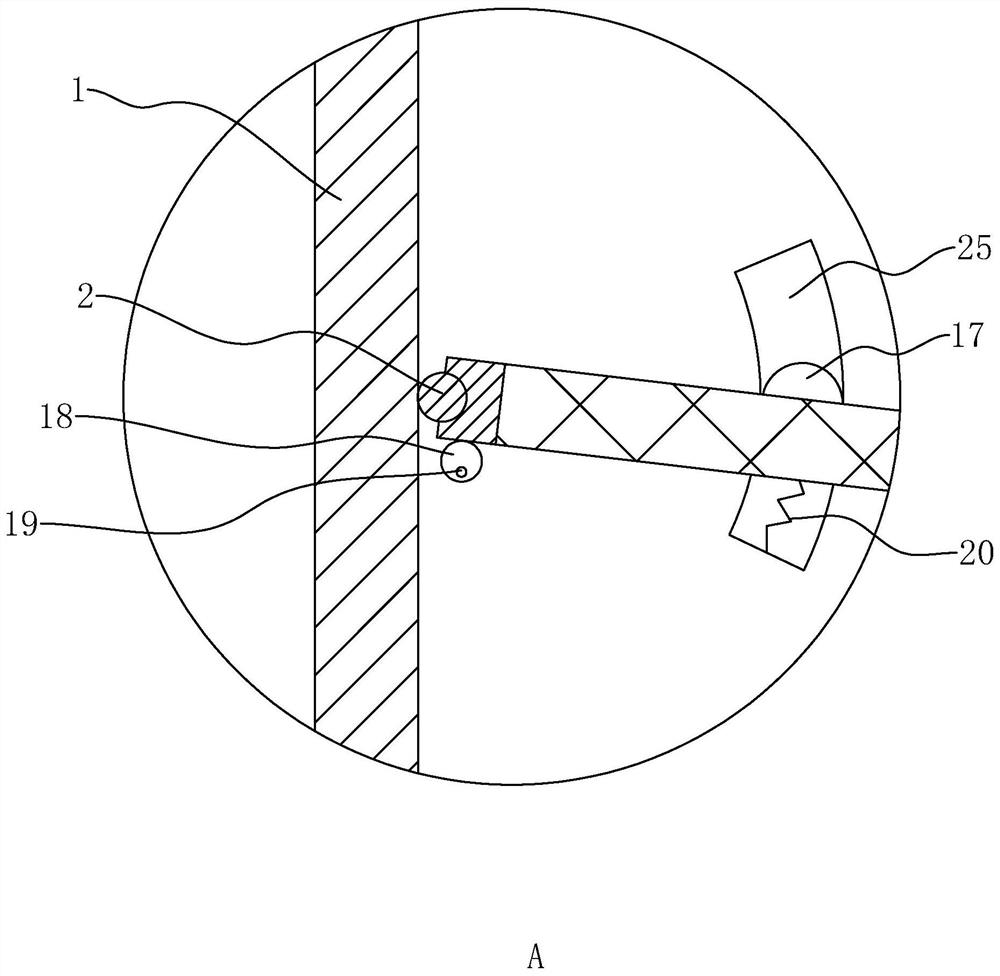

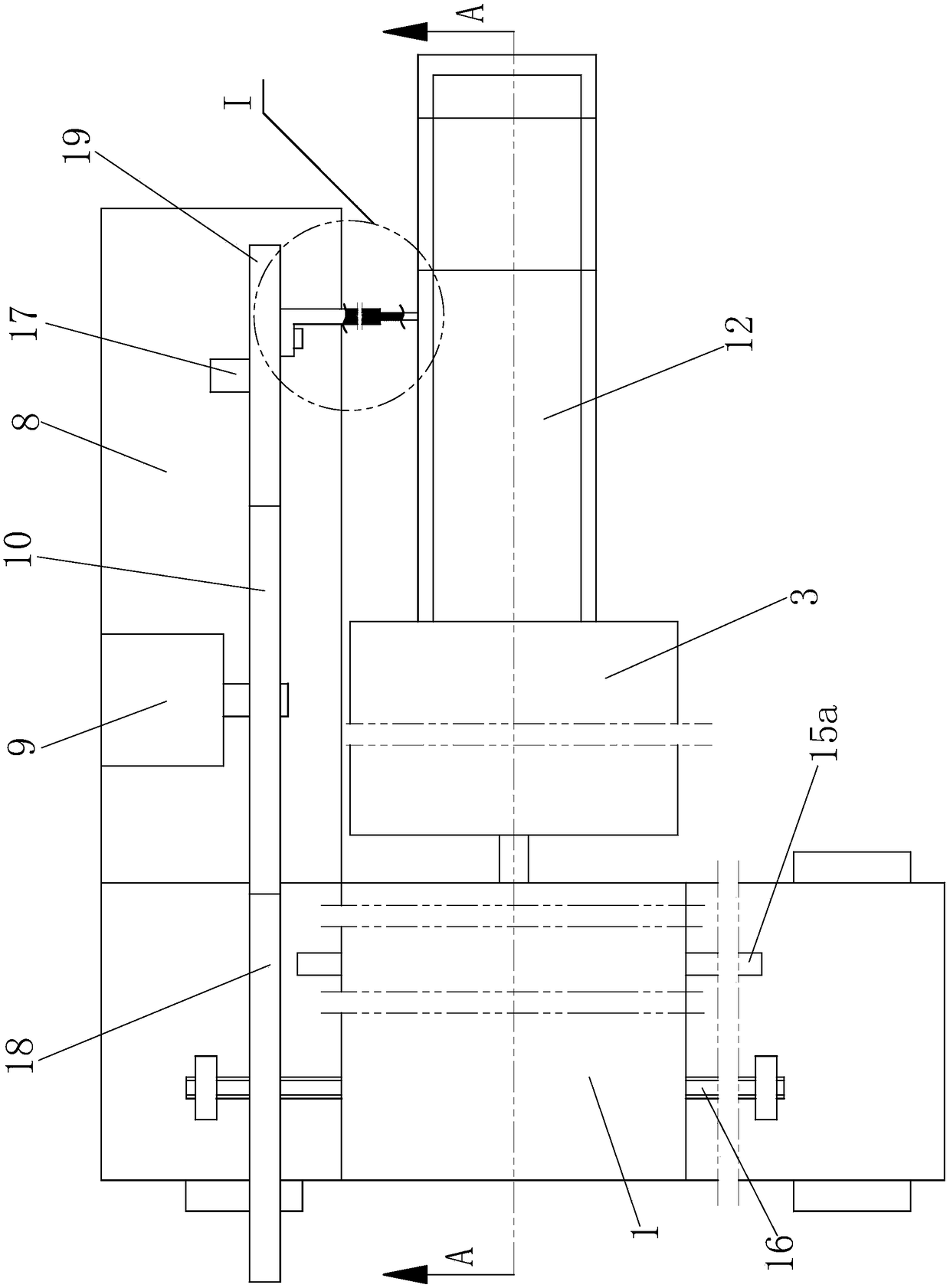

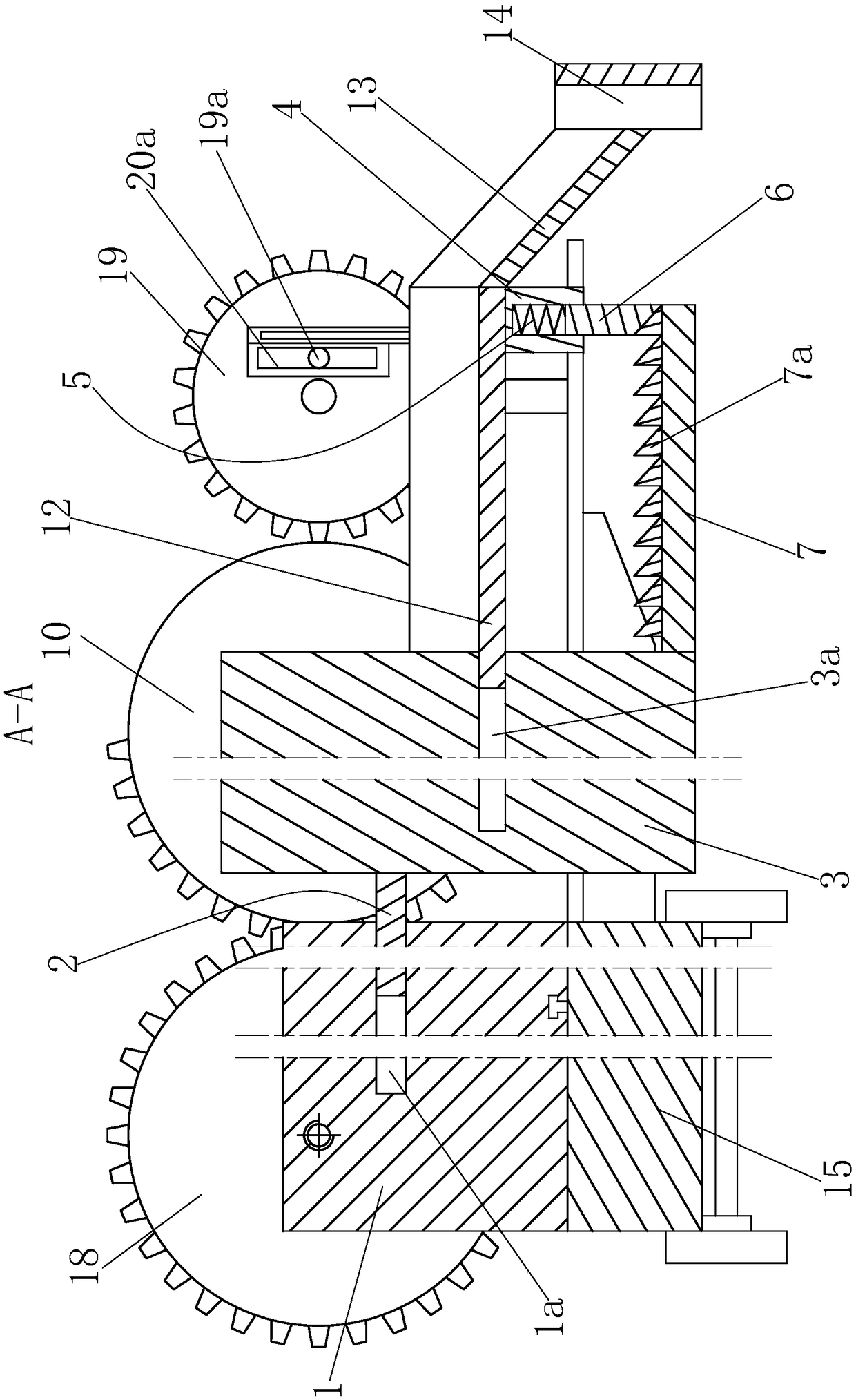

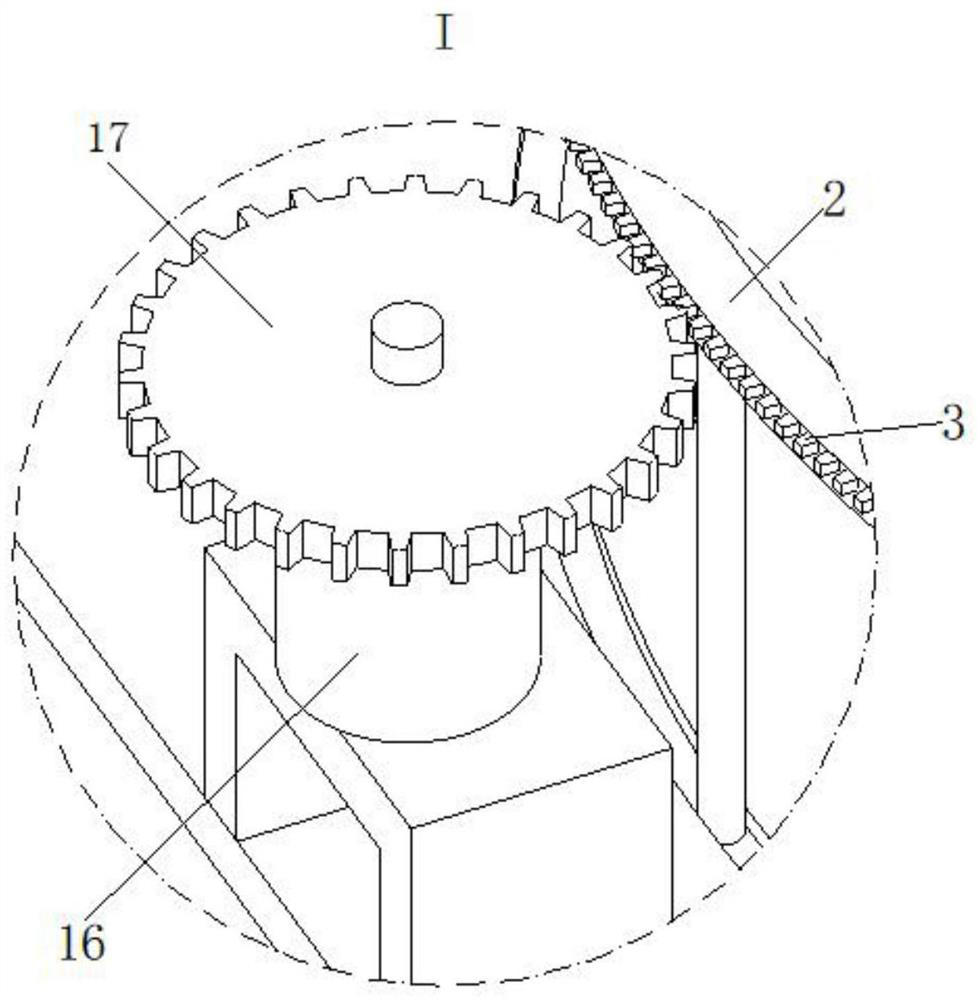

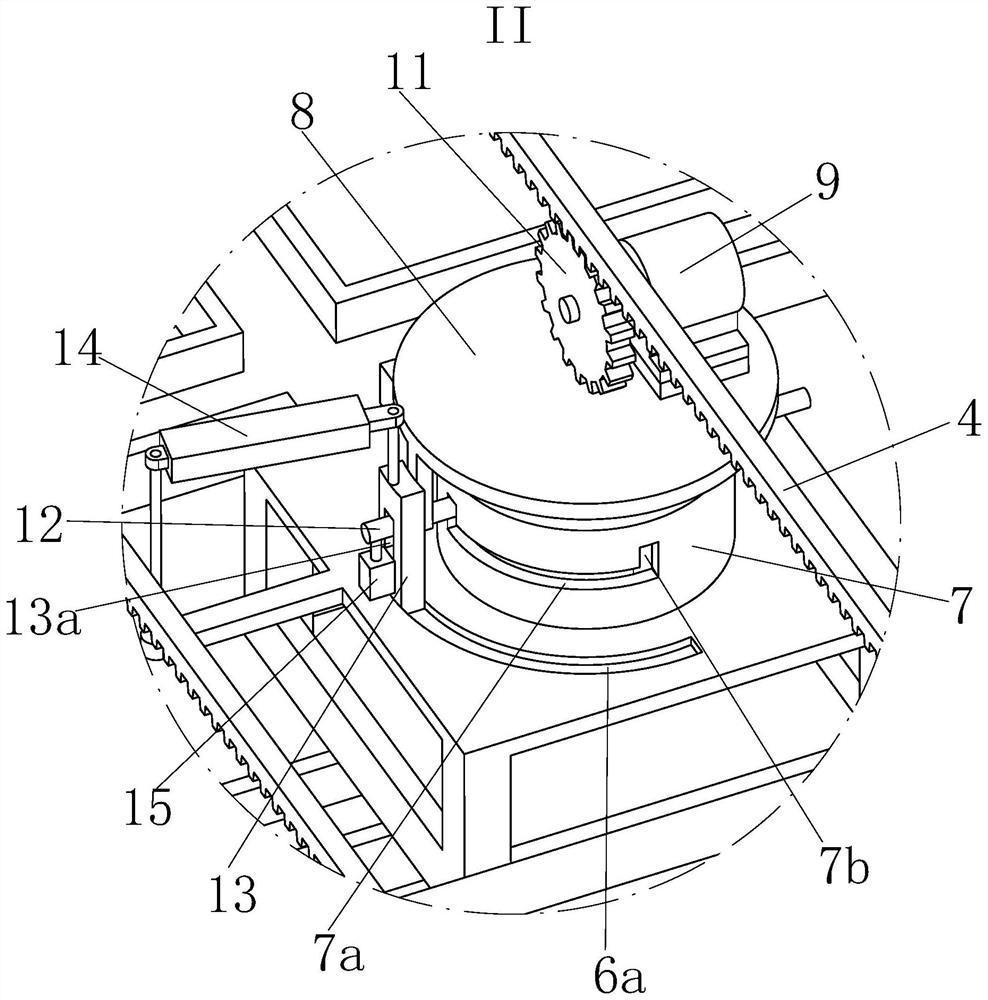

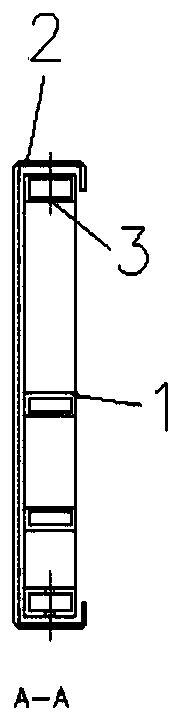

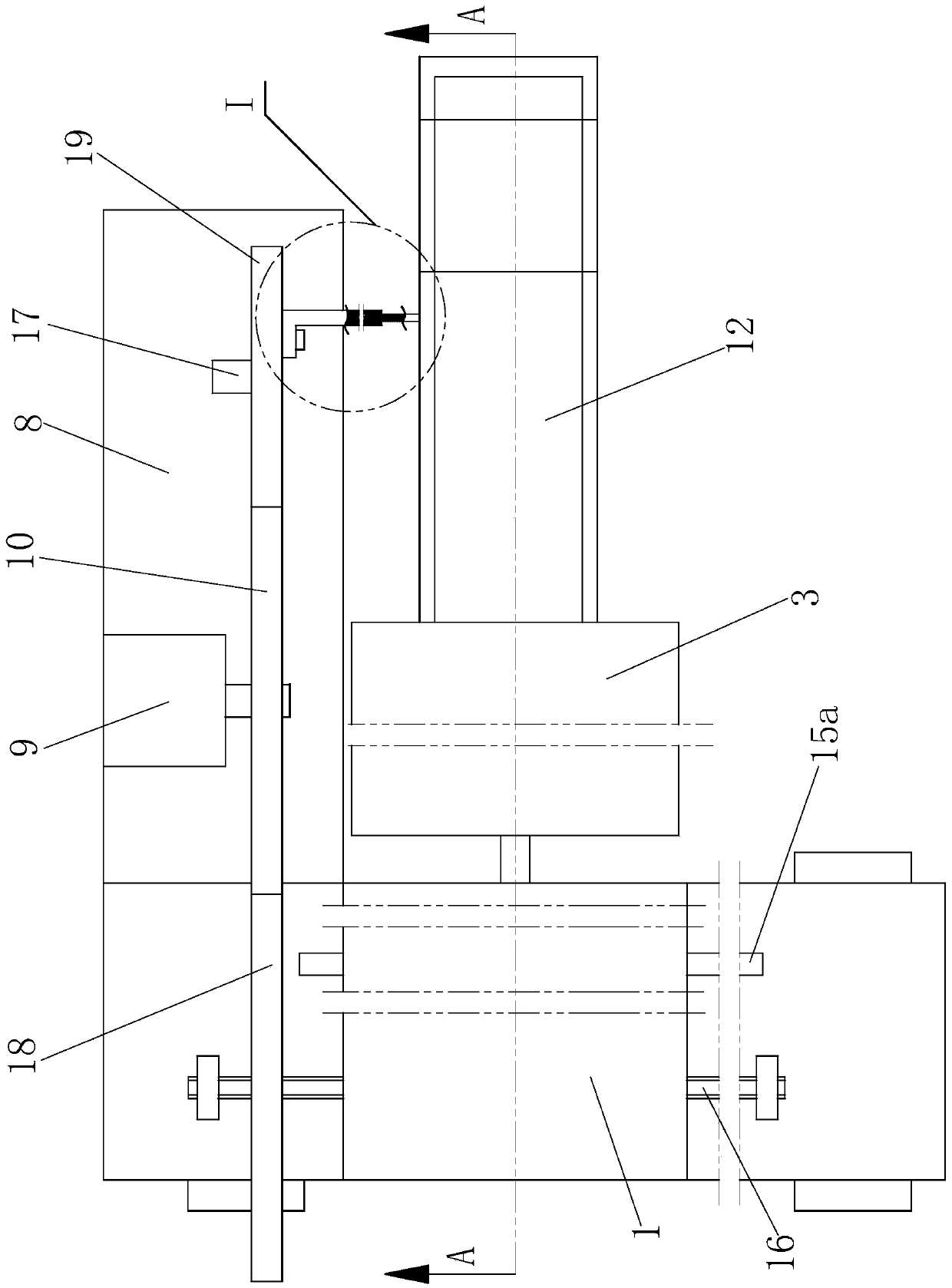

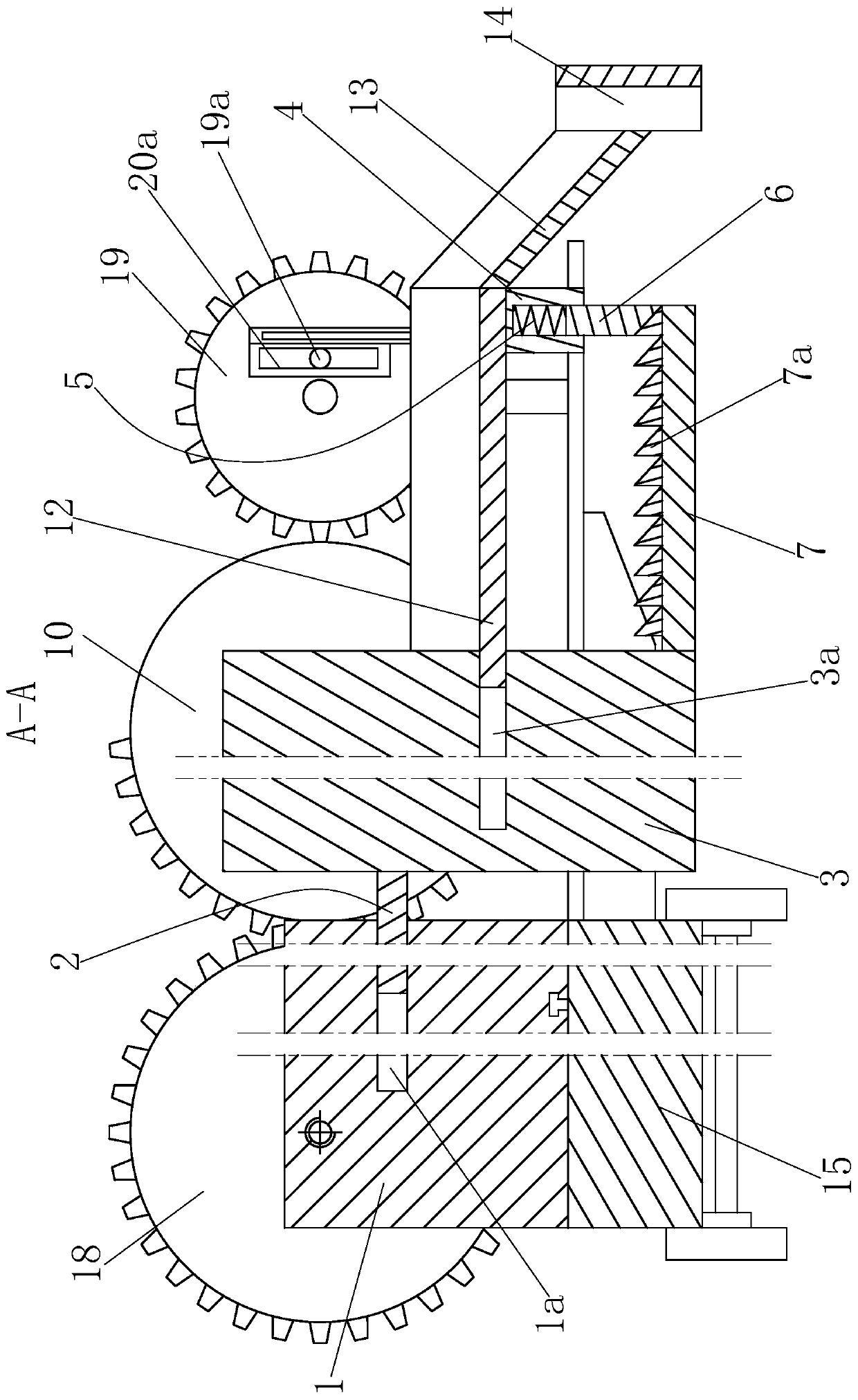

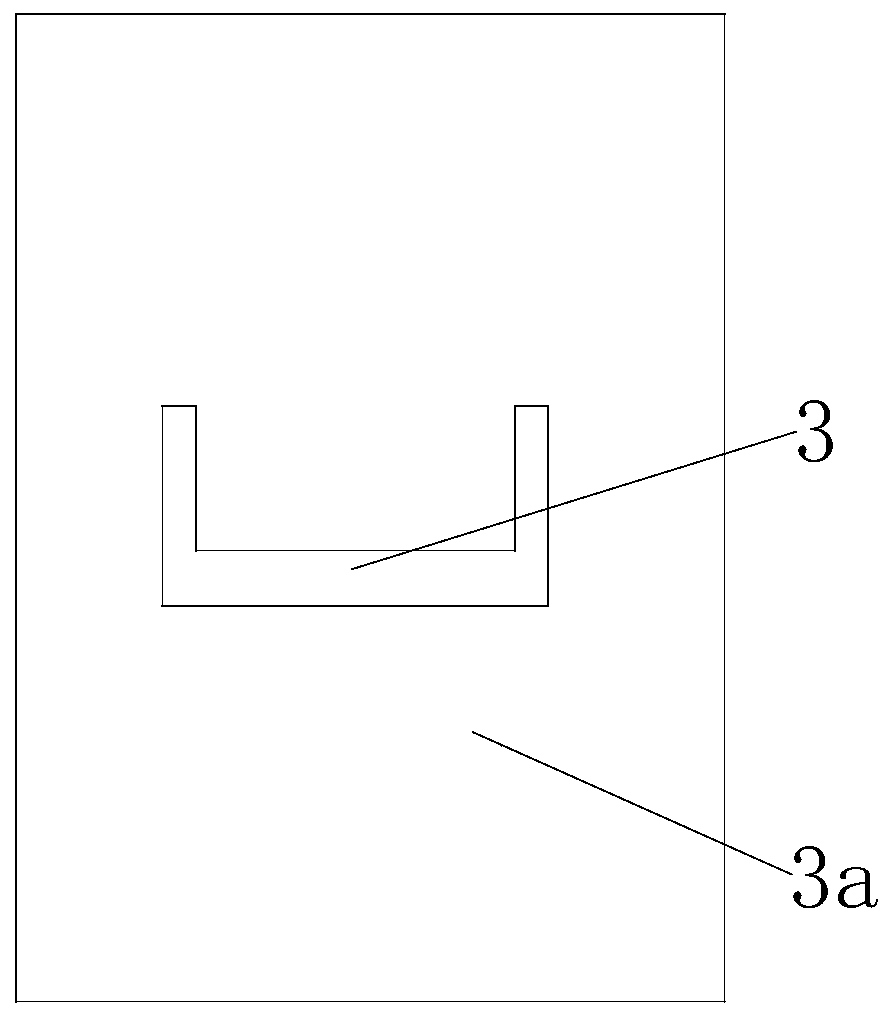

Kerbstone laying and stacking equipment for engineering construction

ActiveCN108951382AHigh degree of automationReduce the amount of manual involvementRoads maintainenceGear toothAutomation

The invention relates to kerbstone laying and stacking equipment for engineering construction. The kerbstone laying and stacking equipment for engineering construction comprises a vehicle body; a slide rail and a lead screw are correspondingly mounted on the vehicle body in a fixing manner and a bearing mounting manner; and a sliding base which is in sliding fit with the front part and the rear part of the slide rail is mounted on the lead screw through threads. A main slide groove is formed in the middle part of the right side of the sliding base; a main rod is slidingly mounted in the main slide groove in the horizontal direction; a mobile base is welded at the right end of the main rod; a sub slide groove with a U-shaped cross section is formed in the upper part of the right side of themobile base; and a slide stacking component is in sliding fit with the right side of the sub slide groove. According to the kerbstone laying and stacking equipment for engineering construction, the automation level is high; through alternate engaged transmission of gear teeth, kerbstone can be automatically stacked at one side edge of a highway in the form of a straight line by alternately supplying a single kerbstone to the right lower side and controlling a lower stone road to move forwards; and moreover, the whole process needs less manpower and the equipment is convenient to control and use.

Owner:南通曲章海洋科技有限公司

Quantitative feed supply device for livestock breeding

ActiveCN112772434ASimple structureHigh degree of automationFood processingAnimal feeding devicesAnimal scienceAgricultural science

The invention discloses a quantitative feed supply device for livestock breeding. According to the technical scheme, the quantitative feed supply device for livestock breeding comprises a first base, a containing groove is formed in the top of the first base, and a feed putting mechanism is arranged at the top of the first base; and the feed putting mechanism comprises a transmission rod and a shell installed at the top of the first base, first bearings are fixedly installed at the two sides of the bottom of the shell, the two ends of the transmission rod are arranged in the two first bearings in a sleeved manner, and a first chain wheel is arranged on the periphery of the middle of the transmission rod in a sleeving manner. According to the quantitative feed supply device, by arranging the feed putting mechanism, under the driving of a servo motor, a storage hopper can be driven to obliquely rotate, so that feed is poured down; and the feed is scooped up through multiple containing hoppers and then thrown out, so that the feed can fall into a feed pool along a discharging hopper, and feed putting is completed.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

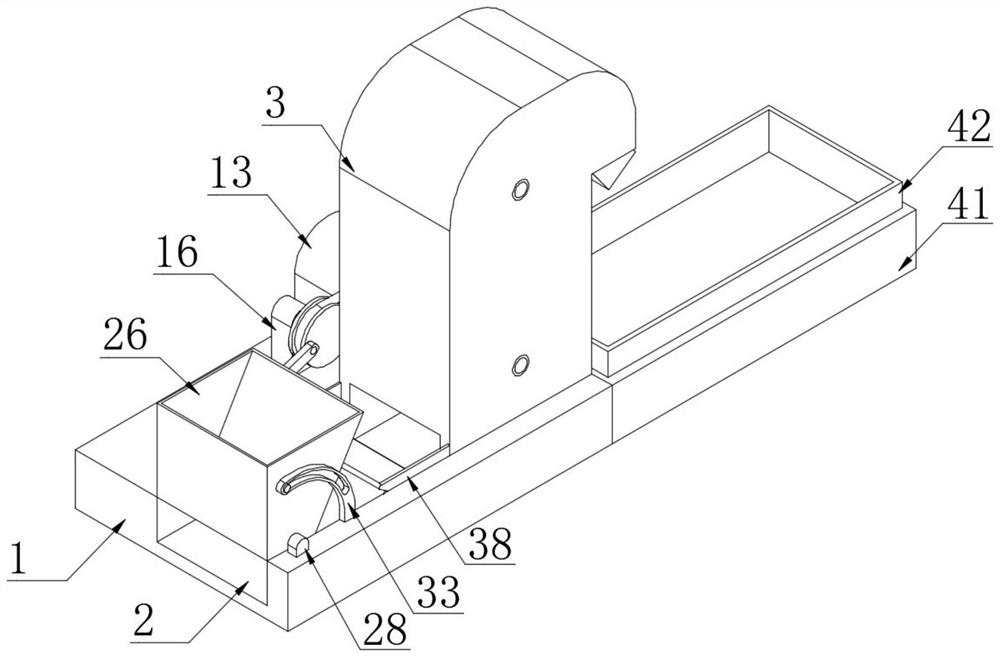

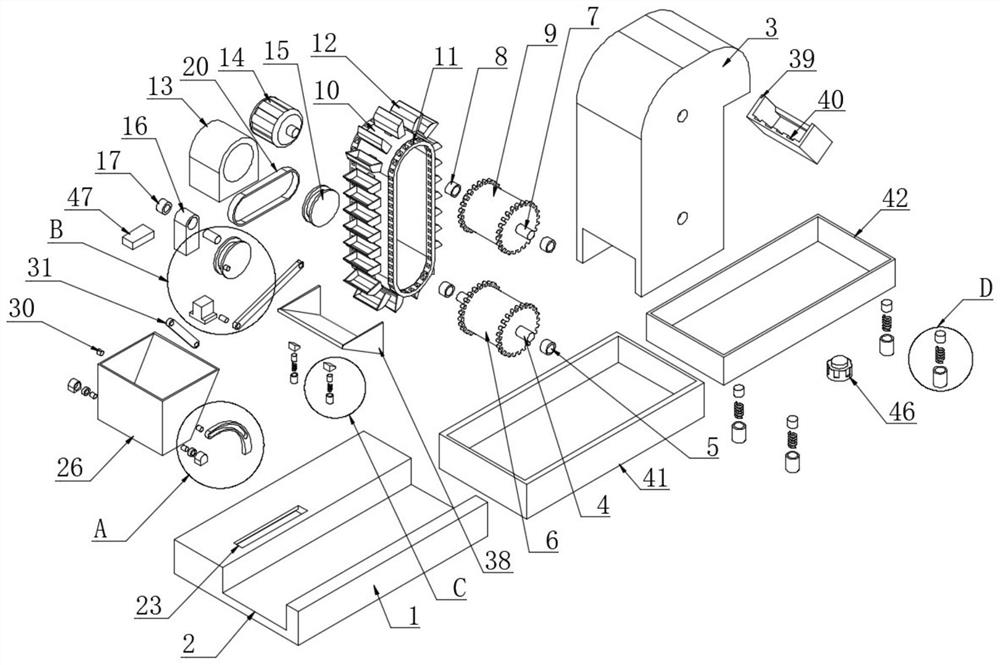

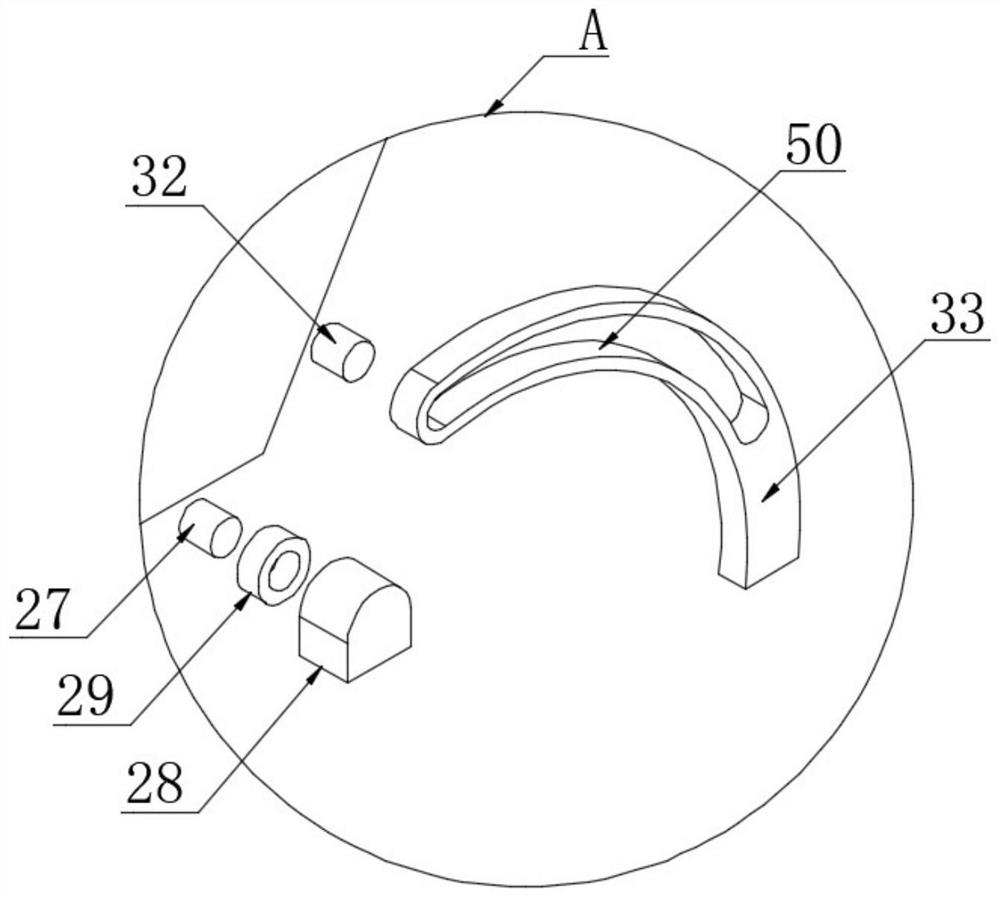

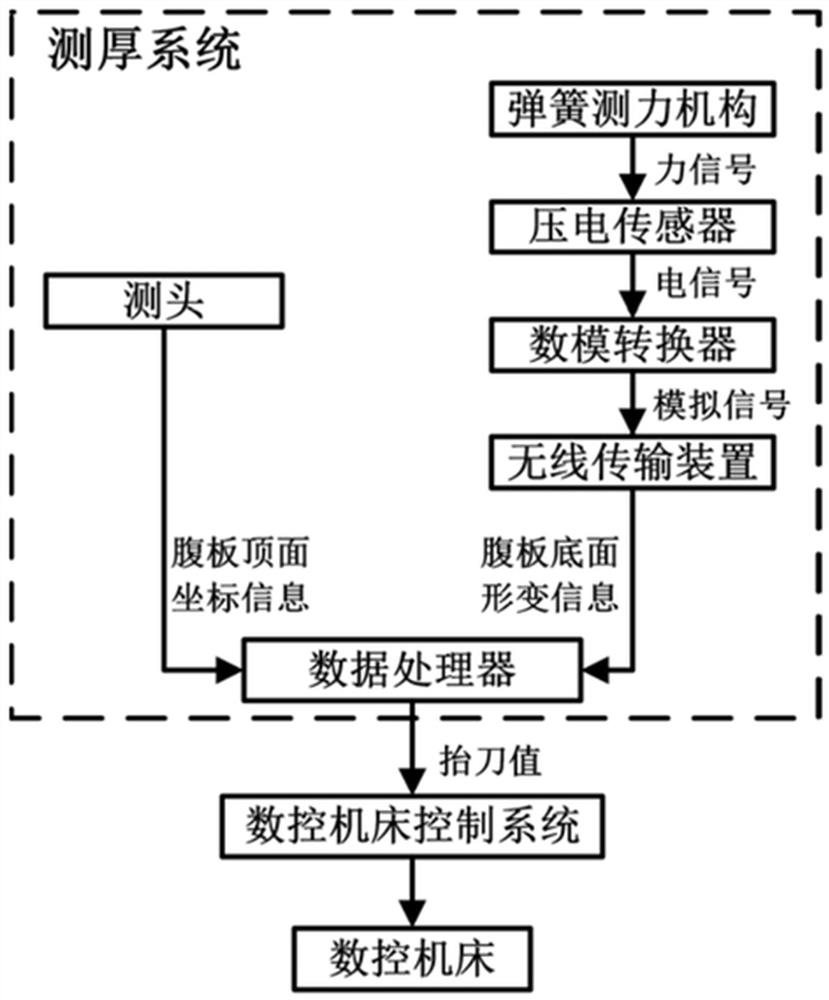

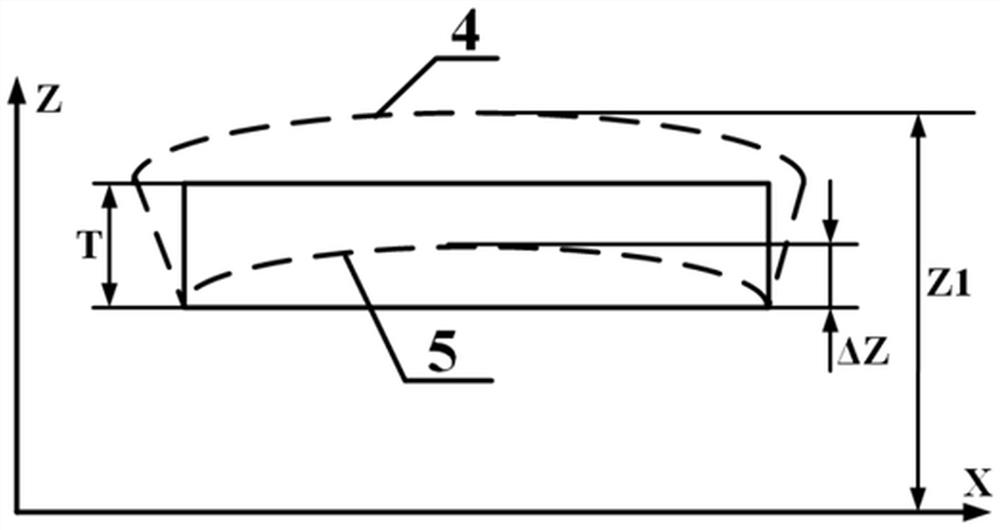

Online thickness monitoring and machining method for large frame and beam part webs

PendingCN113579853ARealize uninterrupted processingMeet the requirements of flexible constructionMeasurement/indication equipmentsNumerical controlControl system

The invention belongs to the technical field of metal cutting machining, and particularly relates to an online thickness monitoring and machining method for large frame and beam part webs. The method comprises the steps that a thickness measuring system is established based on a numerical control machine tool, and the thicknesses of part webs are automatically measured online through the thickness measuring system; the thickness measuring system calculates the error between each actual part web thickness and the theoretical value based on the measured information, the error is input into a control system of the numerical control machine tool, and the control system of the numerical control machine tool generates a part web cutter lifting machining path according to the obtained part web machining theoretical cutter lifting value; and the numerical control machine tool is started to automatically complete supplementary machining of the part webs based on the machining path. According to the technical scheme, automatic measurement and machining of the thicknesses of the part webs are achieved, the risk of manual intervention in machining is reduced, and the method has important significance on flexible construction of a large frame and beam part production line.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

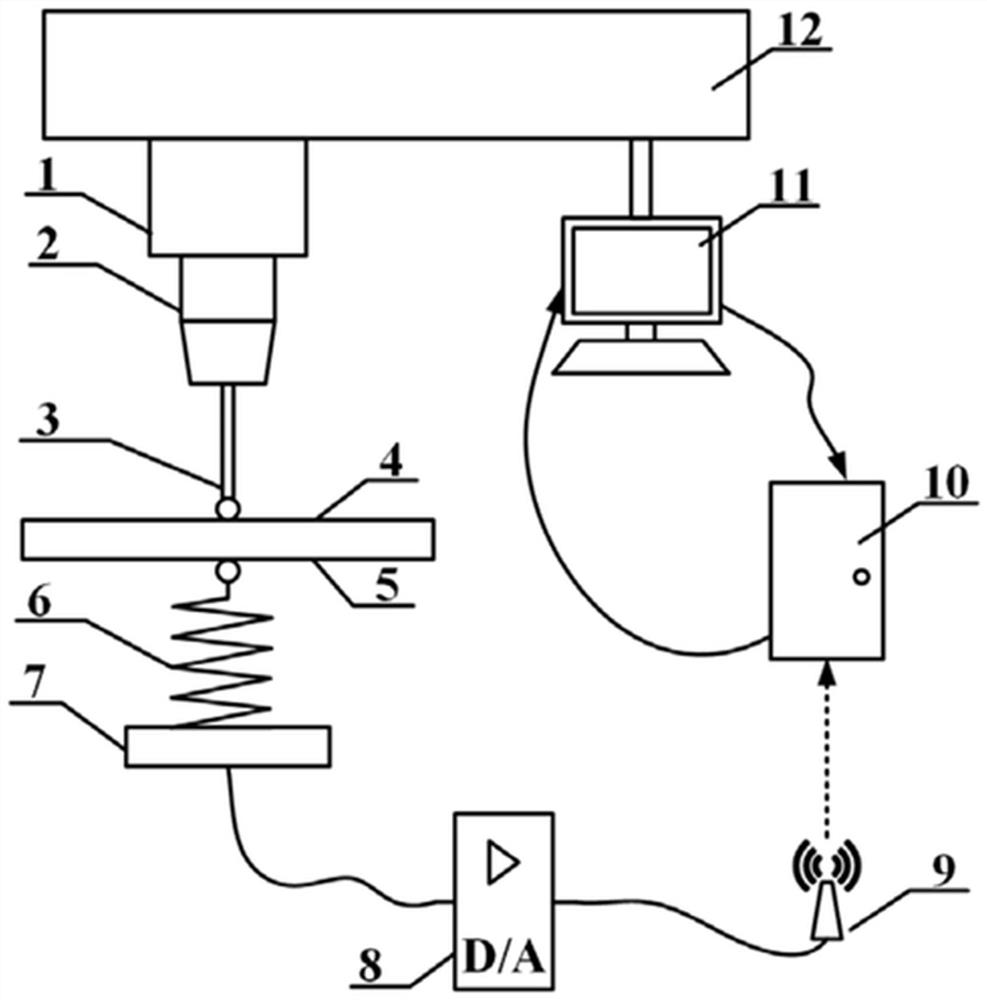

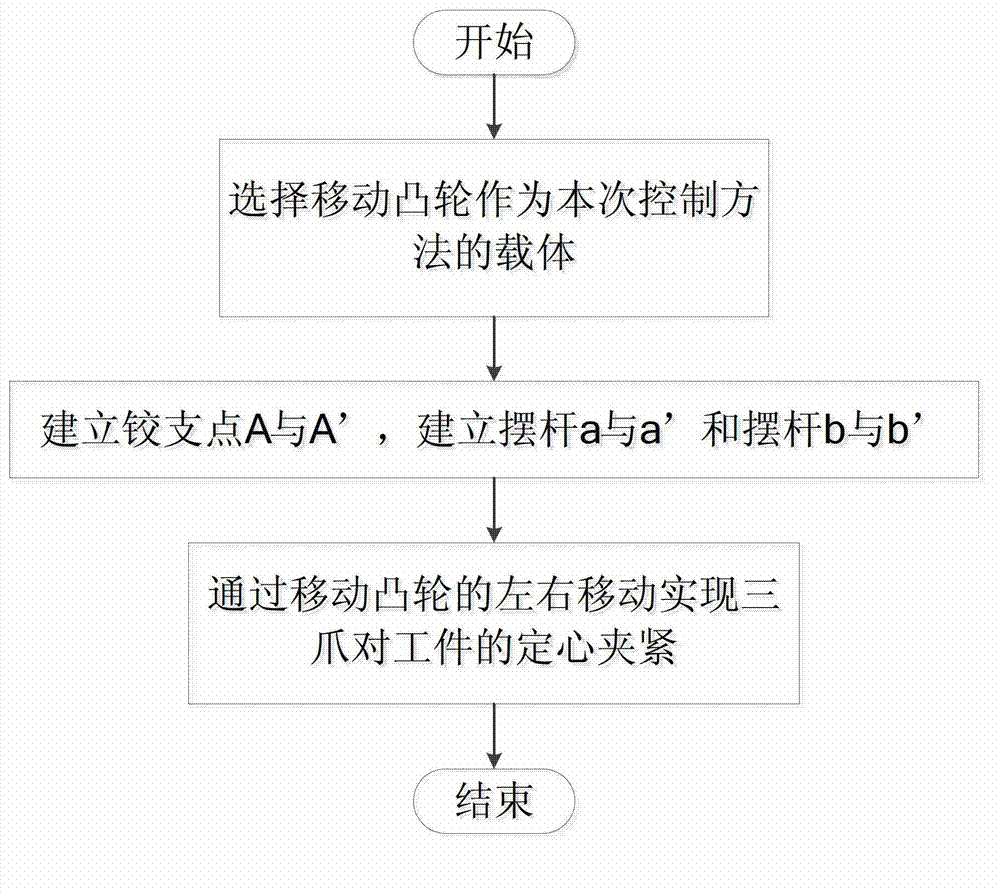

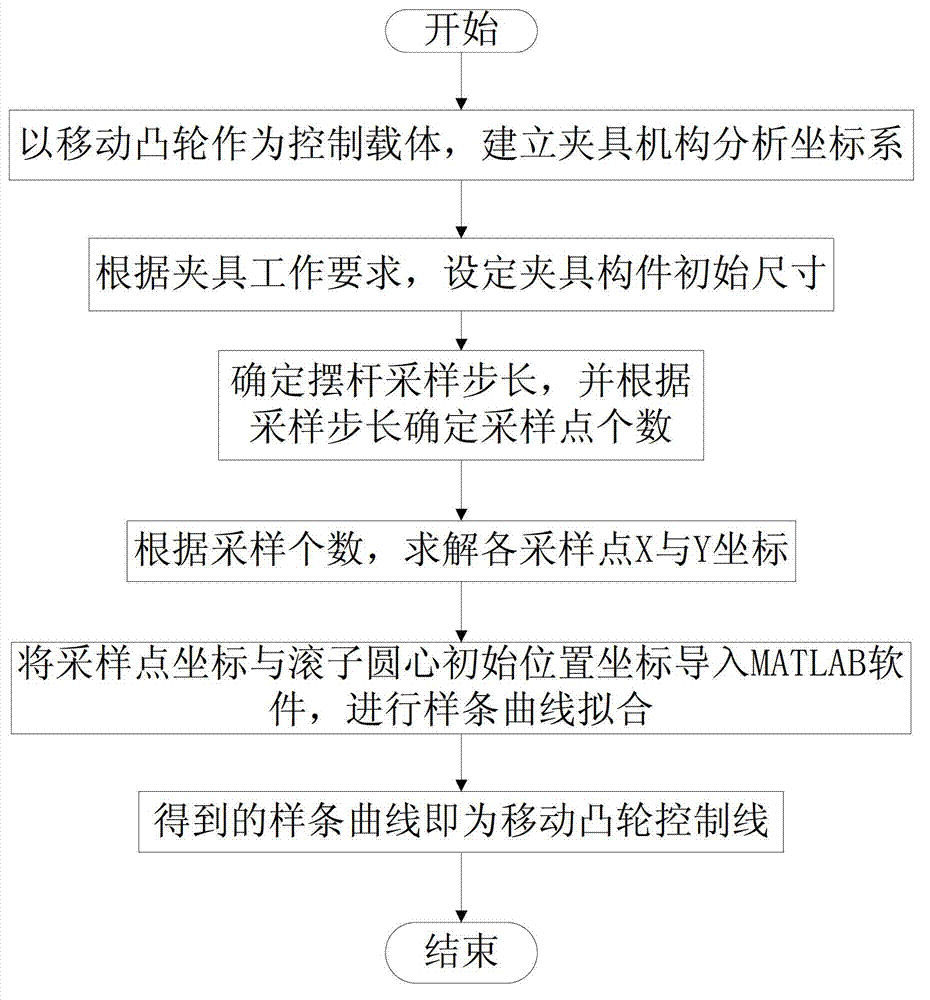

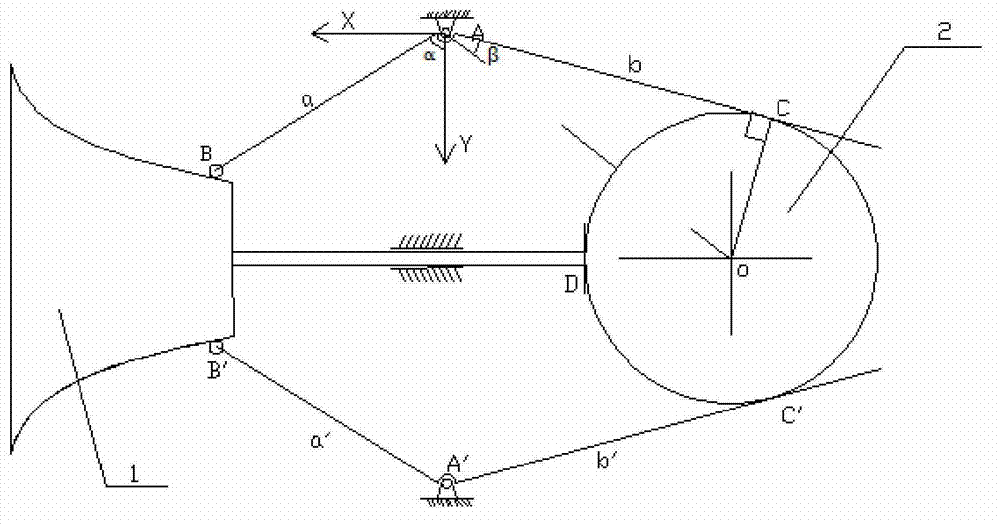

Clamping control method of three-jaw small roller centering fixture

InactiveCN103111648AAvoid formula derivationReduce the amount of manual involvementChucksEngineeringCurve fitting

The invention discloses a clamping control method of a three-jaw small roller centering fixture. A cam is selected as a carrier of the control method of the three-jaw small roller centering fixture. The operating principle of the control method is that clamping operations of the fixture are achieved by utilizing axial movement of the translating cam and through a control line, wherein the control line is obtained through the following steps: analysis coordinates are built, the variable quantity of an included angle of a swing rod a and a Y axis is used as a sampling step length, the circle center position of a roller B is used as a sampling point, the sampling amount is confirmed, X axis and Y axis coordinates of the sampling point are obtained according to the sampling amount, the obtained sampling coordinates is leaded into a matrix laboratory (MATLAB) to conduct spline curve fitting, and the obtained spline curve fitting is the control line of the translating cam. A sampling interpolating solving method id adopted by the control method, and therefore massive formula derivation is avoided, and because interpolating calculation part is procedurally processed by MATLAB software, the manpower participation amount is small, and the method is easy and convenient to use, and fast.

Owner:SOUTHEAST UNIV

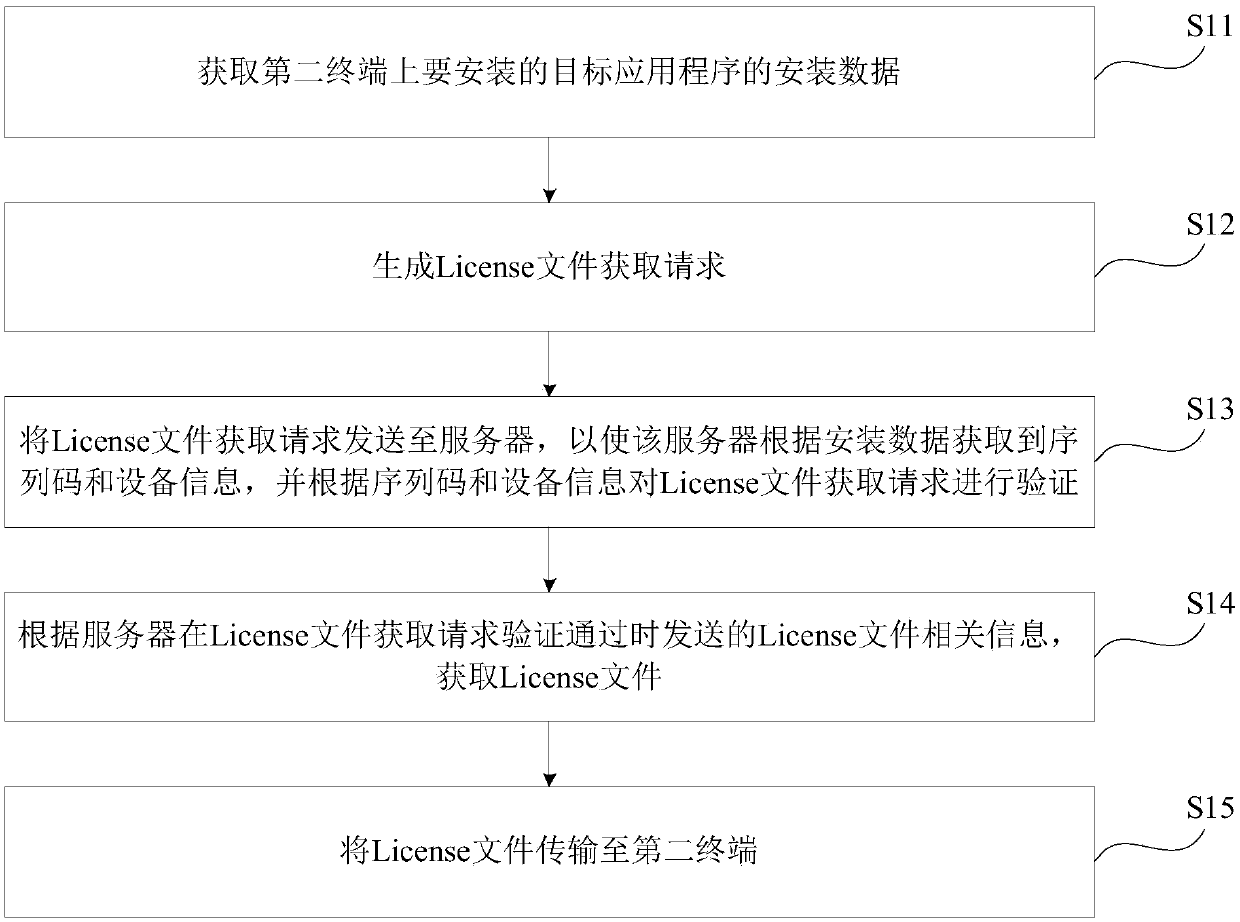

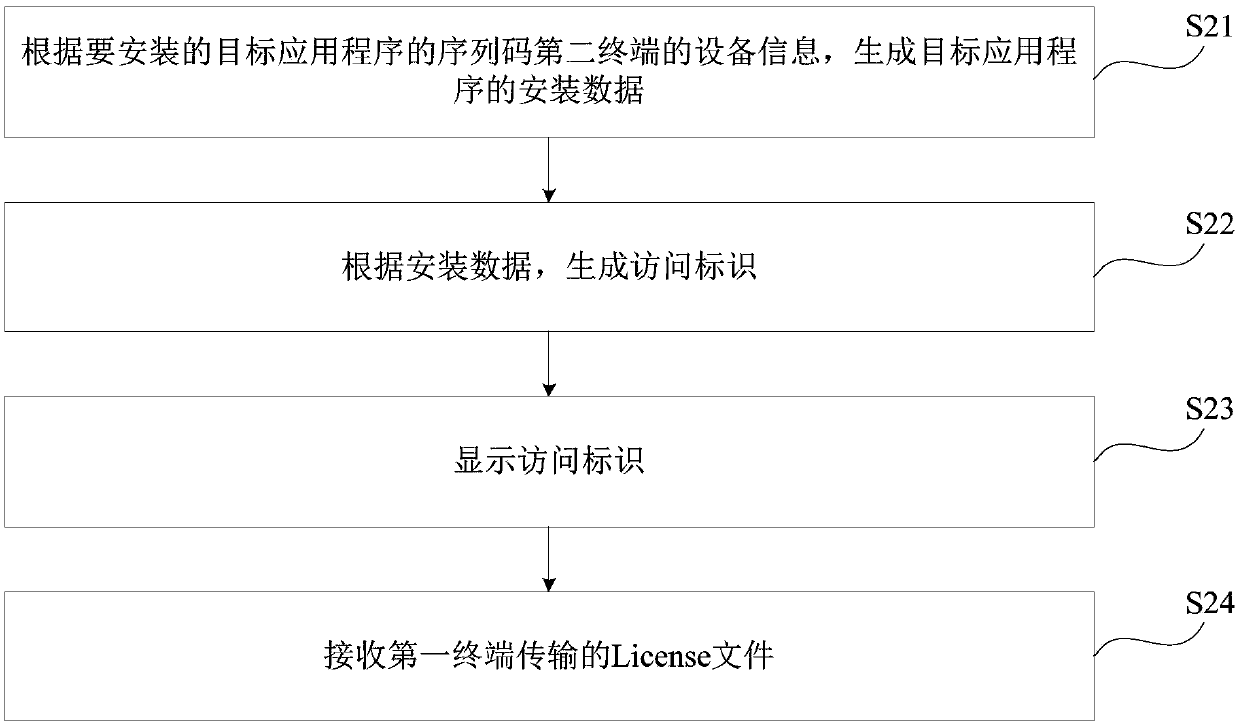

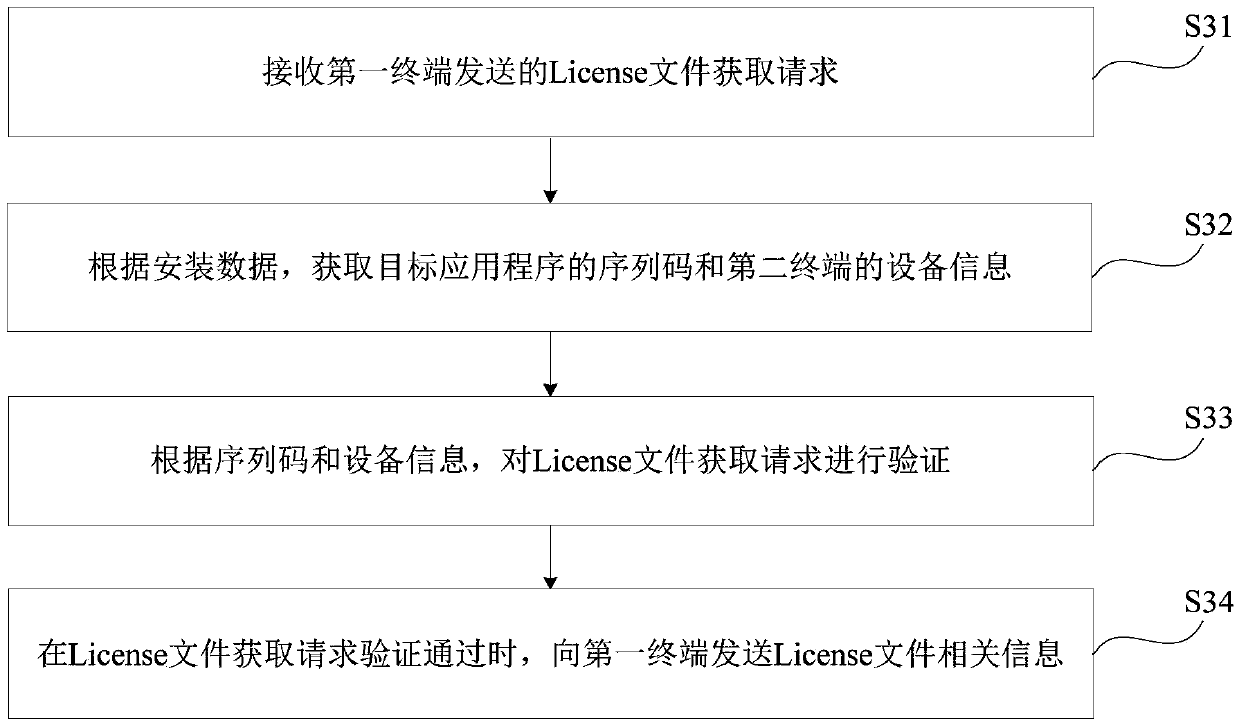

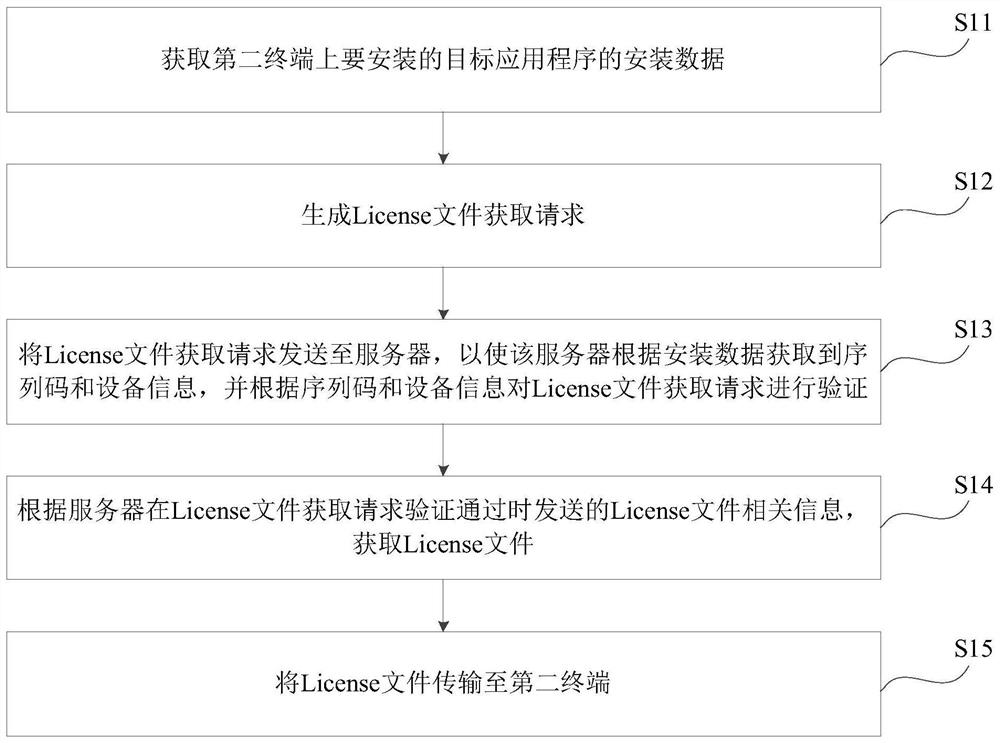

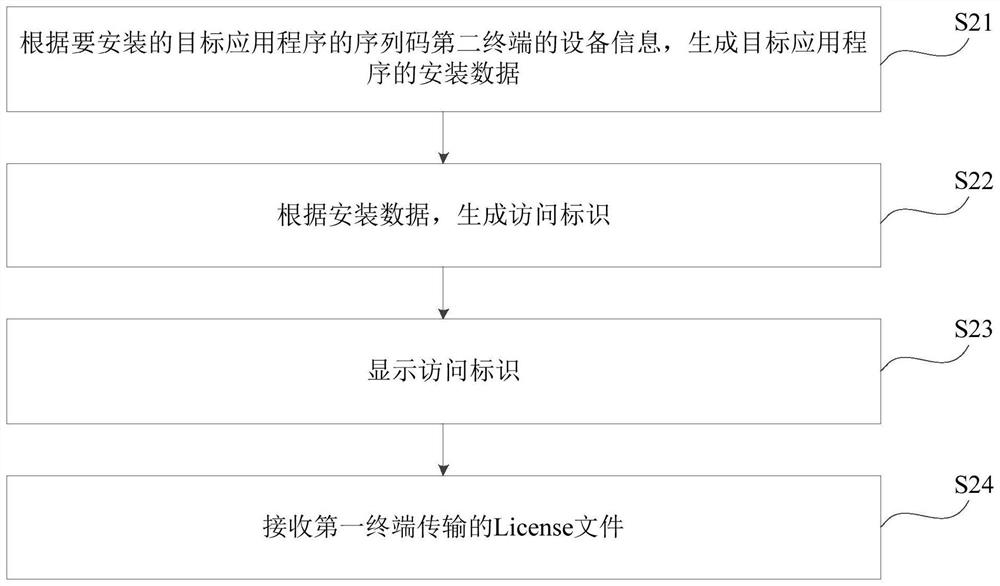

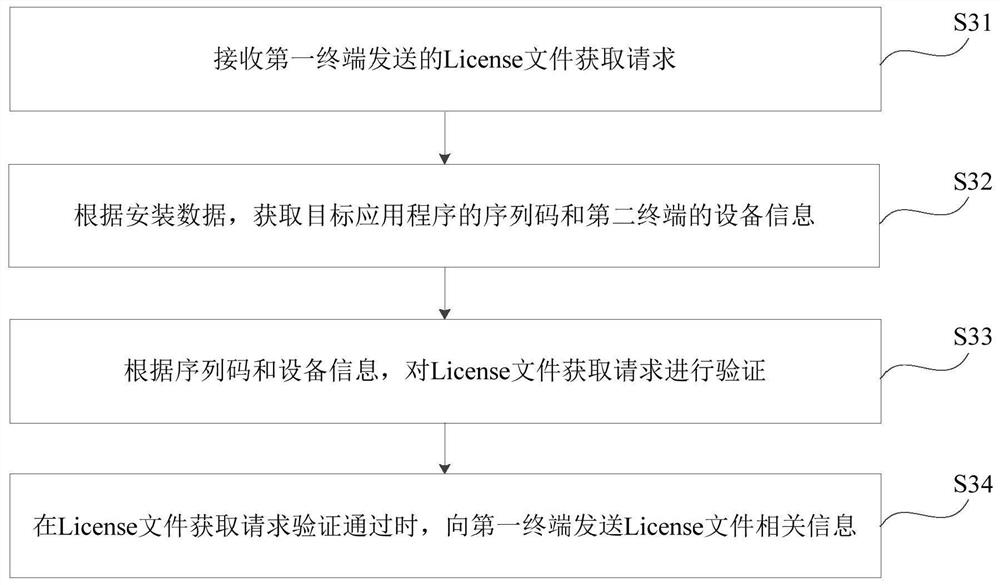

License file acquisition method and device, readable storage medium and electronic equipment

ActiveCN109614114ASimplify the process of obtaining license filesImprove intelligenceSoftware deploymentComputer terminalApplication software

The invention relates to a License file acquisition method and device, readable storage medium and electronic equipment. The method comprises the steps of acquiring installation data of a target application program to be installed on a second terminal by a first terminal; generating a License file acquisition request; sending the License file acquisition request to a server, so that the server acquires a sequence code of a target application program and equipment information of a second terminal according to the installation data, and verifying the License file acquisition request according tothe sequence code and the equipment information; and the first terminal obtains the License file according to the License file related information sent by the server when the License file obtaining request passes the verification, and transmits the License file to the second terminal. By the adoption of the technical scheme, a user does not need to manually input information needed for obtainingthe License file, the manual participation amount is reduced, the process that the user obtains the License file is simplified, and the intelligence of obtaining the License file and the satisfactiondegree of the user are improved.

Owner:NEUSOFT CORP

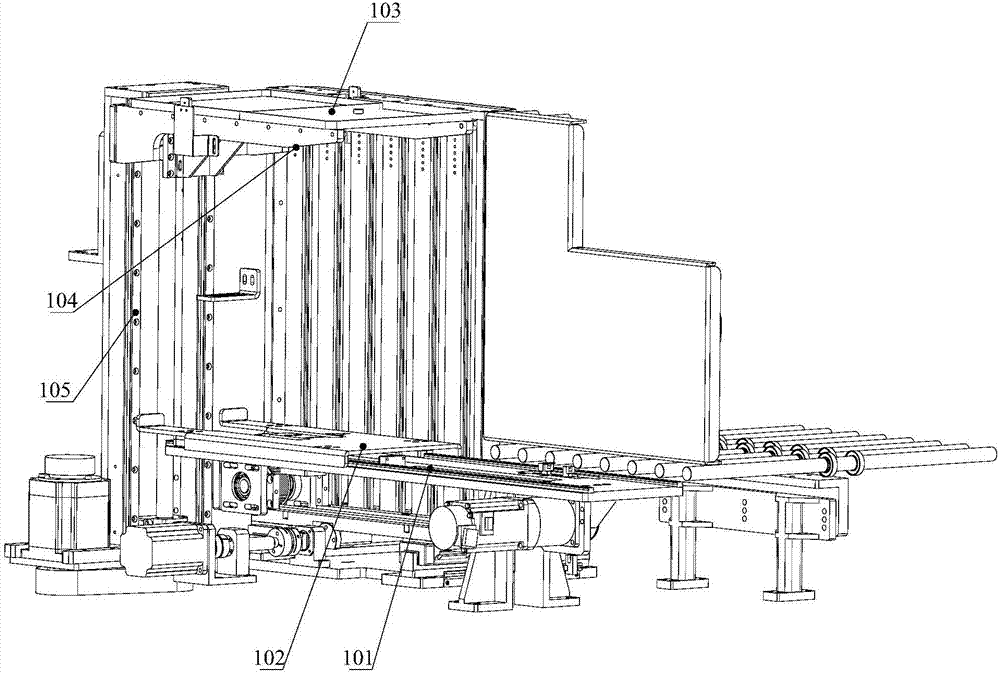

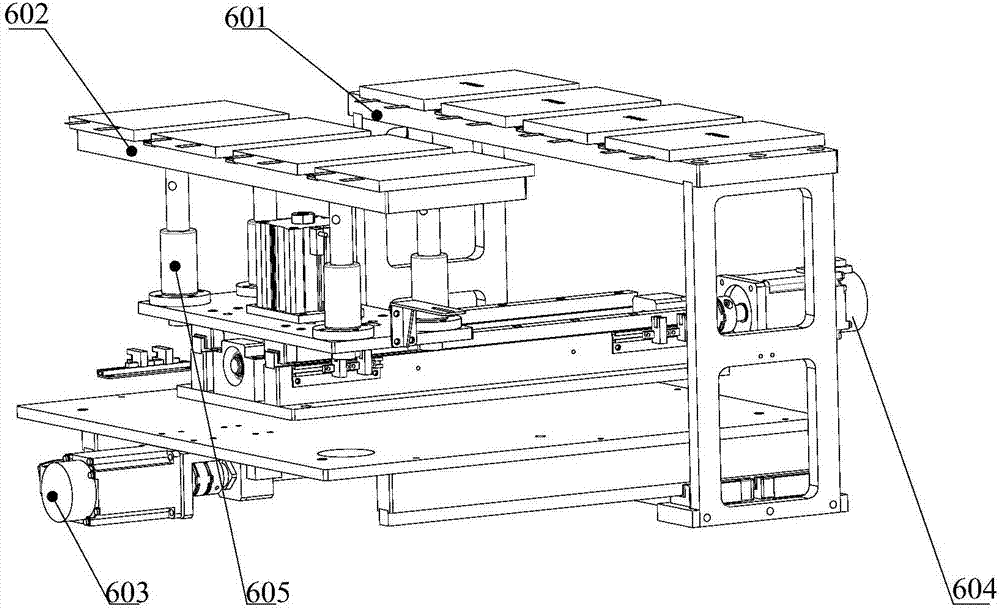

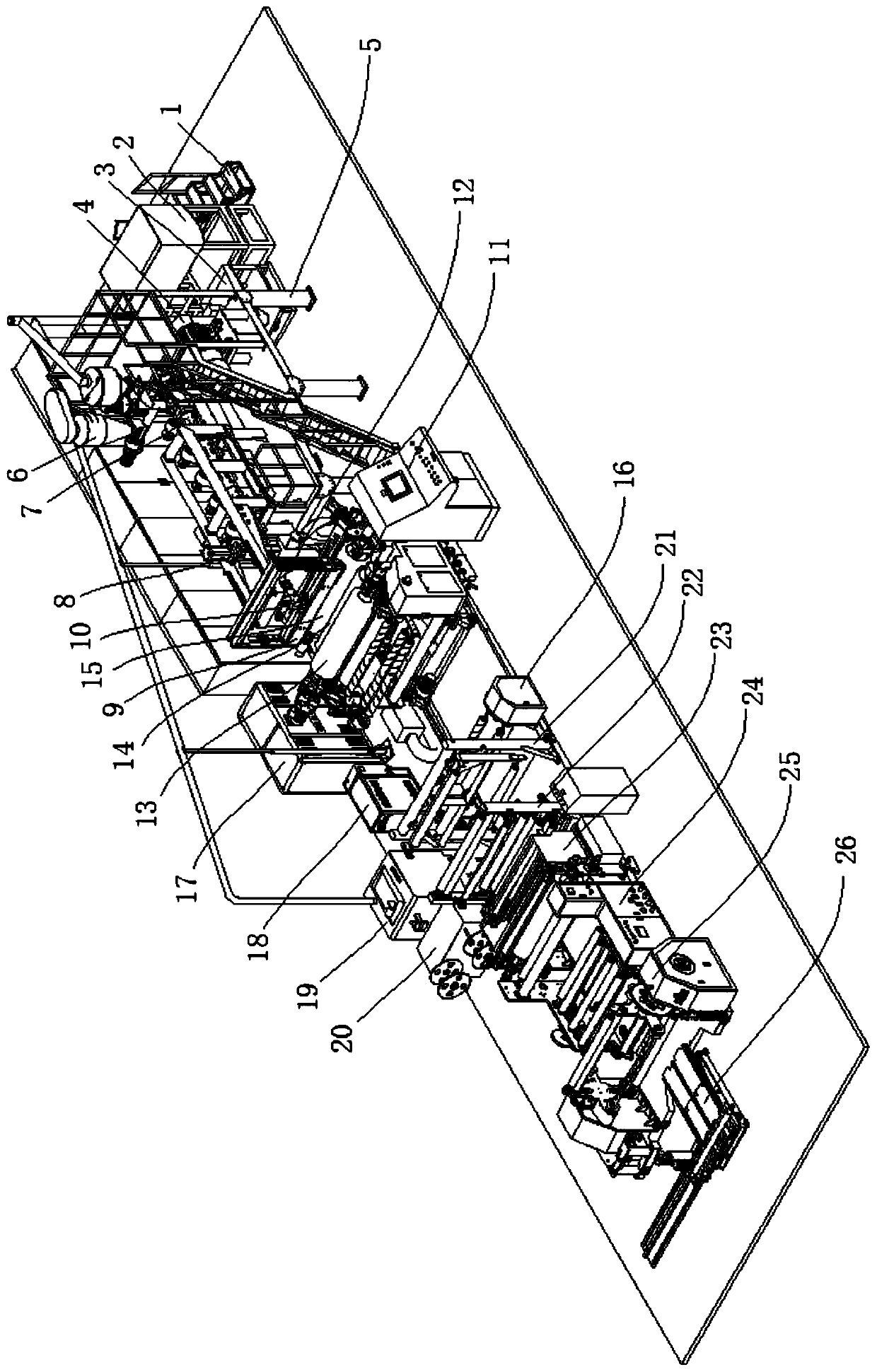

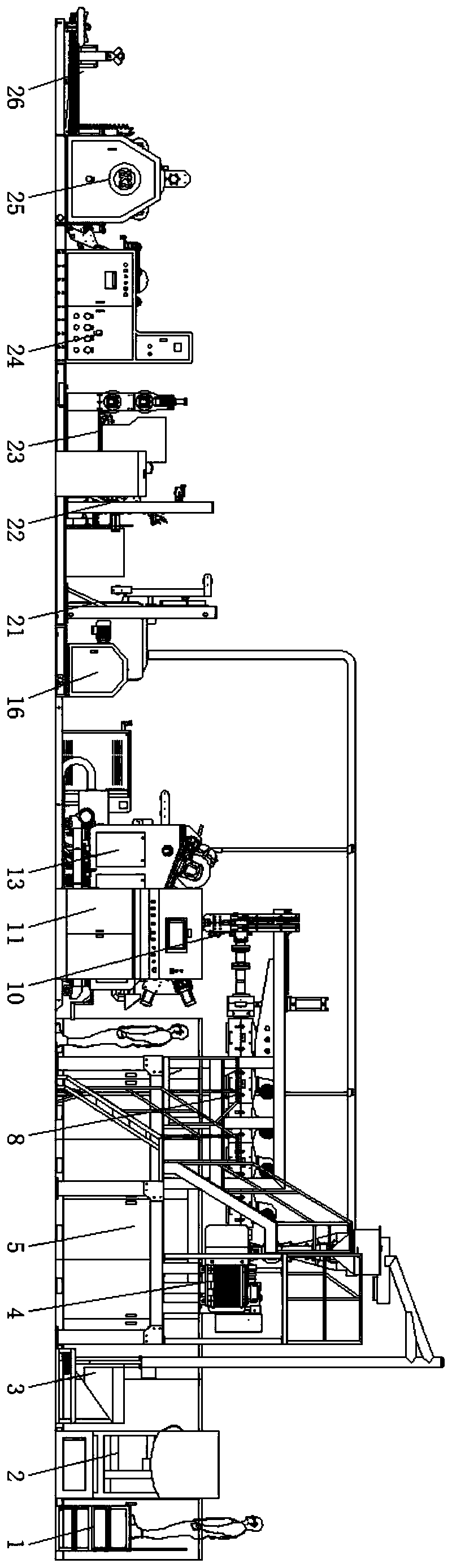

A general production line automation equipment and process method

ActiveCN106584130BReduce workloadOptimize and simplify the processOther manufacturing equipments/toolsProduction lineAutomation

The invention discloses general production line automatic equipment and a process method. The general production line automatic equipment comprises a processing part, a screening part, an arrangement part, an operating part and a trolley loading part. A powder blowing and dust collecting system is arranged at the front end of the processing part. The screening part is arranged at the rear end of the processing part. The arrangement part is arranged on the right side of the screening part. The operating part is arranged on the right side of the arrangement part. The trolley loading part is arranged on the right side of the operating part. The front end of the processing part is connected with the powder blowing and dust collecting system, the rear end of the processing part communicates with the screening part, the right end of the screening part communicates with the left end of the arrangement part, and the right end of the arrangement part communicates with the left end of the trolley loading part. The invention further provides the process method of the general production line automatic equipment. The general production line automatic equipment and the process method thereof have the beneficial effects that a conventional production line type product packaging process is optimized and simplified, and the general automatic packaging equipment for standard components is provided.

Owner:昆山庆腾欣金属实业有限公司

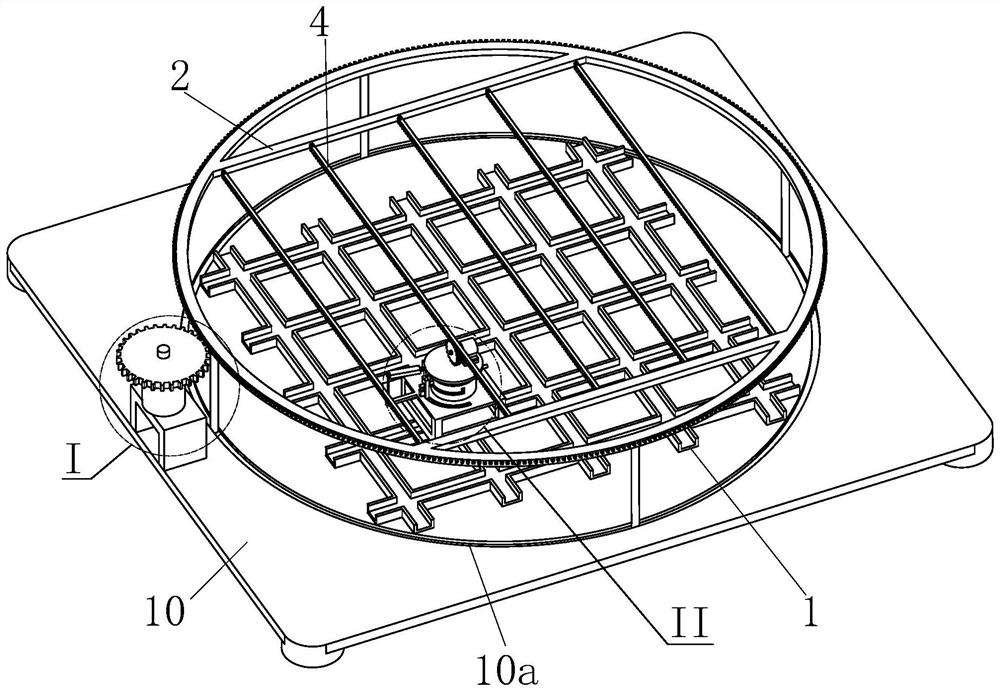

Cargo exchange conveying platform and using method thereof

PendingCN114852567ACan deliver many pointsRealize circulation and transportationStorage devicesStructural engineeringMechanical engineering

The invention relates to a goods exchange conveying platform and a using method thereof.The goods exchange conveying platform comprises a main cushion table, and a rail frame and a rotatable bearing frame are installed on the upper side of the main cushion table; an annular gear ring and a plurality of racks are respectively mounted at the upper part of the bearing frame; the annular gear ring is connected with an auxiliary changing assembly. A square column is installed on the rail frame in a sliding mode, a loading main frame is welded to the upper end of the square column, and a main positioner matched with the rack is arranged on the upper portion of the loading main frame. According to the goods conveying device, the number of conveying points is relatively large, goods can be freely converted from the horizontal conveying direction to the vertical conveying direction, and therefore circulation and transportation of the goods between any two storage points can be achieved on the plane. The whole transportation process is convenient to operate and control, the manual participation amount is small, and manpower is relatively saved.

Owner:WUHU OCEANIC LOGISTIC CO LTD

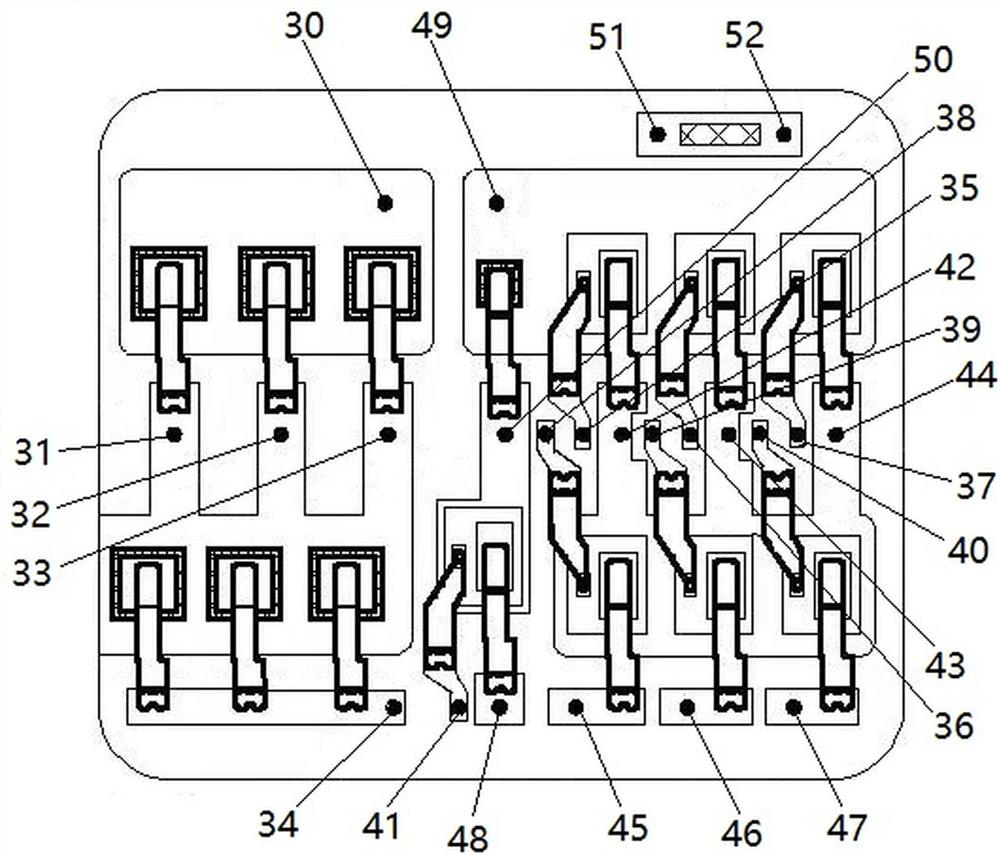

A kind of pim device and manufacturing method thereof

ActiveCN113556026BGood thermal cycle performanceShape stableAC motor controlSemiconductor/solid-state device detailsDevice materialHemt circuits

Owner:乐山希尔电子股份有限公司 +1

General production line automatic equipment and process method

ActiveCN106584130AReduce workloadOptimize and simplify the processOther manufacturing equipments/toolsProduction lineManufacturing engineering

The invention discloses general production line automatic equipment and a process method. The general production line automatic equipment comprises a processing part, a screening part, an arrangement part, an operating part and a trolley loading part. A powder blowing and dust collecting system is arranged at the front end of the processing part. The screening part is arranged at the rear end of the processing part. The arrangement part is arranged on the right side of the screening part. The operating part is arranged on the right side of the arrangement part. The trolley loading part is arranged on the right side of the operating part. The front end of the processing part is connected with the powder blowing and dust collecting system, the rear end of the processing part communicates with the screening part, the right end of the screening part communicates with the left end of the arrangement part, and the right end of the arrangement part communicates with the left end of the trolley loading part. The invention further provides the process method of the general production line automatic equipment. The general production line automatic equipment and the process method thereof have the beneficial effects that a conventional production line type product packaging process is optimized and simplified, and the general automatic packaging equipment for standard components is provided.

Owner:昆山庆腾欣金属实业有限公司

A shaving machine for feather removal

ActiveCN110978069BTo achieve the separation effectEasy to useMetal working apparatusHydraulic cylinderStructural engineering

The invention relates to a shaving machine for removing handles from feathers. plate; a capping plate is provided above each limiting plate. A hanger is installed at the rear of the seat, and a hydraulic cylinder is installed on the hanger, and the hydraulic cylinder is connected with a cutter matched with the limit plate. The invention is easy to use, and on the basis of installing and limiting the feathers, it can effectively shave the pinna part of the feathers, achieve the effect of separating the hairs of the feathers from the handle, and the amount of manual participation in the entire shaving process Less and more efficient shaving.

Owner:无为县三祥商贸有限公司

Manufacturing method for cabinet board

PendingCN111230419ADegree of reductionSmall error in section sizeWelding apparatusLaser cuttingMachine

The invention discloses a manufacturing method for a cabinet board, and relates to the field of rubber processing. The method comprises the following steps of: Step 1: preparing closed-end profile steel for processing a frame; Step 2: preparing a metal clad plate; Step 3: using a laser cutting machine to make holes in the metal clad plate in advance; Step 4: using the laser cutting machine to cutthe closed-end profile steel and make holes in the closed-end profile steel; Step 5: using a clamp to fix the pre-cut and tapped closed-end profile steel on processing equipment, performing batch welding by a robot to generate a square frame with four edges in rigid connection; and Step 6: wrapping the metal clad plate outside the square frame to ensure that the error value between the metal cladplate and the connection hole corresponding to the square frame is smaller than a preset error threshold value. The manufacturing method for the cabinet board improves processing efficiency and processing positioning accuracy.

Owner:海南信荣橡胶机械有限公司

Curb stone laying and stacking equipment for engineering construction

ActiveCN108951382BHigh degree of automationReduce the amount of manual involvementRoads maintainenceArchitectural engineeringGear tooth

The invention relates to kerbstone laying and stacking equipment for engineering construction. The kerbstone laying and stacking equipment for engineering construction comprises a vehicle body; a slide rail and a lead screw are correspondingly mounted on the vehicle body in a fixing manner and a bearing mounting manner; and a sliding base which is in sliding fit with the front part and the rear part of the slide rail is mounted on the lead screw through threads. A main slide groove is formed in the middle part of the right side of the sliding base; a main rod is slidingly mounted in the main slide groove in the horizontal direction; a mobile base is welded at the right end of the main rod; a sub slide groove with a U-shaped cross section is formed in the upper part of the right side of themobile base; and a slide stacking component is in sliding fit with the right side of the sub slide groove. According to the kerbstone laying and stacking equipment for engineering construction, the automation level is high; through alternate engaged transmission of gear teeth, kerbstone can be automatically stacked at one side edge of a highway in the form of a straight line by alternately supplying a single kerbstone to the right lower side and controlling a lower stone road to move forwards; and moreover, the whole process needs less manpower and the equipment is convenient to control and use.

Owner:南通曲章海洋科技有限公司

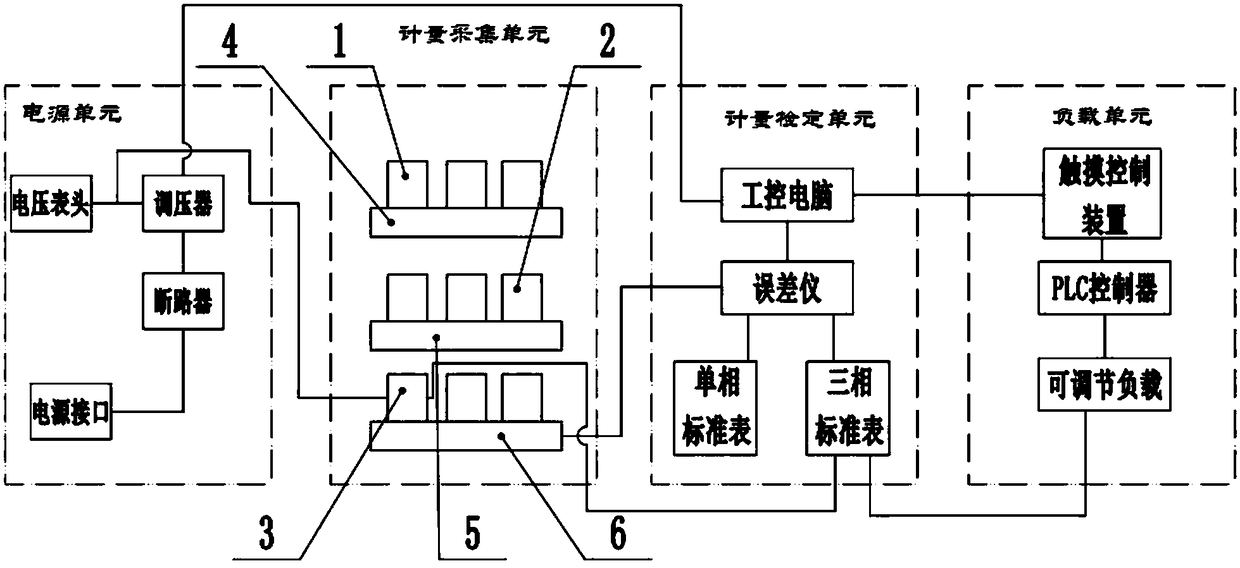

A measurement stability test system and test method for electric energy meters

ActiveCN106054113BHas reference valueThe test effect is goodElectrical measurementsCommunication interfaceMachine control

The invention discloses a metering stability testing system for electric energy meter and testing method thereof, including a power supply unit interface configured with a power supply interface and a voltage regulator in connection with the power supply interface through a circuit breaker and an electric energy meter support configured with a meter to be tested. The meter support is provided with a communication interface connected with the to-be-tested electric energy meter, an output interface connected with the communication interface, and a sliding groove cooperating with the bottom of the to-be-tested electric energy meter as well as a rotation clamped metering acquisition unit that has the to-be-tested electric energy meter fixedly arranged in the sliding groove. The meter support is also configured with an industrial control computer and an error instrument connected with industrial control computer. The error instrument can be connected with the output end of all types of standard electric energy meters and is interfaced to the output end of the electric energy meters. The industrial control machine controls the metering calibration unit and the loading unit of the voltage regulator simultaneously.

Owner:国网山东省电力公司营销服务中心(计量中心) +2

An automatic classification system and classification method for web comments based on association rules

ActiveCN103473262BGuaranteed uptimeImprove efficiencySpecial data processing applicationsElectricityFeature extraction

The invention discloses an association rule-based automatic classification system and classification method for Web comment opinions, which can be divided into four modules: a frequent feature word extraction module, a frequent feature word optimization module, an association rule extraction and mining module, and an opinion classification module. The present invention overcomes the shortcomings of existing systems (such as some systems based on machine learning and emotion classification) that have low precision or require a large amount of human participation or rely too much on natural language processing and professional knowledge. In addition, optimization is carried out in the process of extracting association rule sets, and redundant and indiscriminate association rules are removed, which improves the efficiency of the entire system operation and obtaining results. This system provides an accurate and convenient solution for a variety of situations, such as e-commerce product evaluation, e-government feedback, and Internet user polls.

Owner:珠海市颢腾智胜科技有限公司

License file acquisition method, device, readable storage medium and electronic equipment

ActiveCN109614114BSimplify the process of obtaining license filesImprove intelligenceSoftware deploymentEngineeringDatabase

The present disclosure relates to a license file acquisition method, device, readable storage medium and electronic equipment. The method includes: the first terminal obtains the installation data of the target application program to be installed on the second terminal; generates a license file acquisition request; sends the license file acquisition request to a server, so that the server obtains the license file according to the installation data. The serial code of the target application program and the device information of the second terminal, and verify the license file acquisition request according to the serial code and the device information; the first terminal sends the license file related information according to the license file acquisition request verification passed by the server , obtain the license file, and transfer the license file to the second terminal. With the above technical solution, the user does not need to manually input the information required for obtaining the license file, which reduces the amount of manual participation, simplifies the process for the user to obtain the license file, and improves the intelligence of obtaining the license file and user satisfaction.

Owner:NEUSOFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com