PIM device and manufacturing method thereof

A device and control electrode technology, applied in the field of PIM devices and their manufacturing, can solve the problems of slow production efficiency, poor power-on capability, and high process difficulty, and achieve the effects of reducing production error rates, clear connection points, and simplifying circuit structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

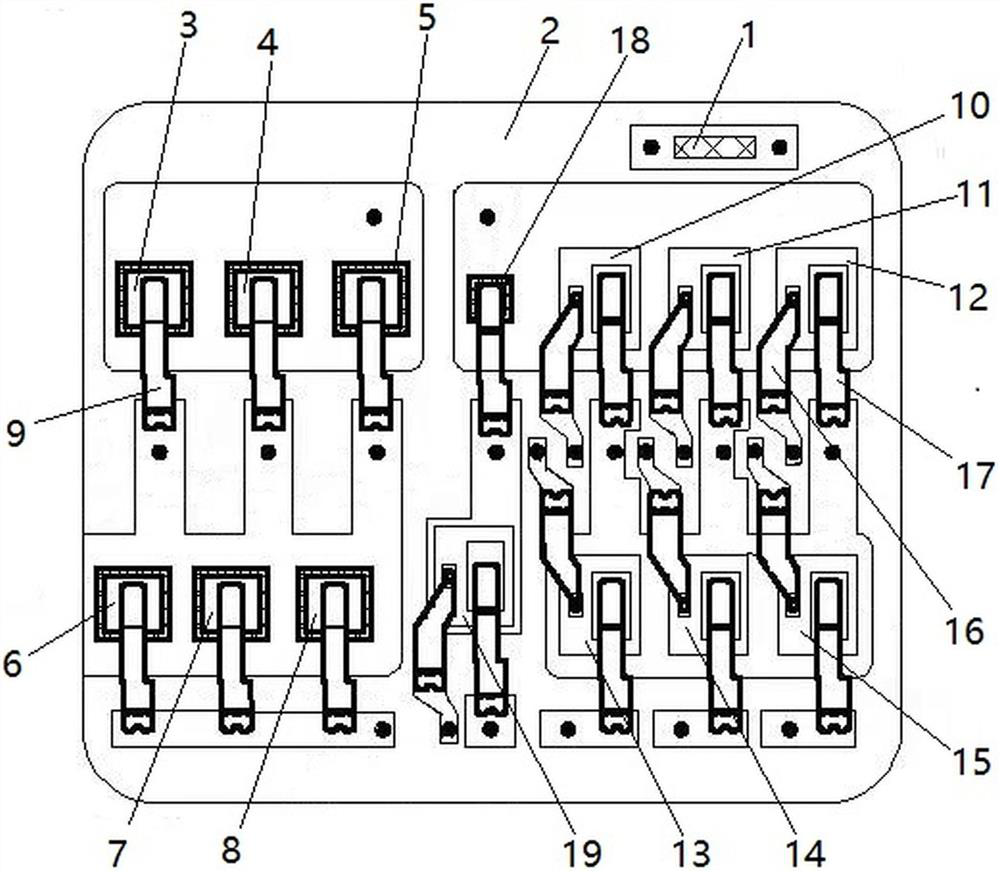

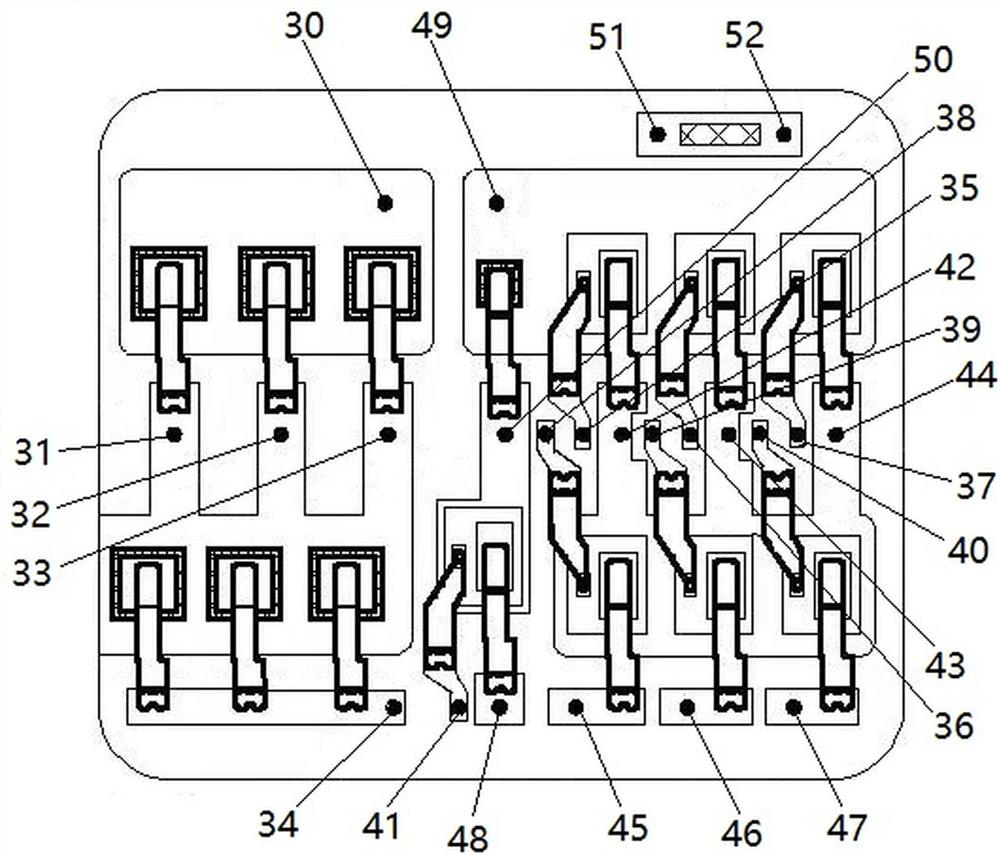

[0048] This embodiment discloses a PIM device, as a basic implementation of the technical solution, including a copper-clad ceramic substrate, a three-phase rectification unit, a three-phase inverter unit, a braking unit and a temperature control detection NTC device 1 .

[0049] The three-phase rectifier unit includes six diode chips arranged on a copper-clad ceramic substrate and clip copper sheets 9 corresponding to the six diode chips, and the six diode chips are diode chip I3, diode chip II4, and diode chip III5. , diode chip Ⅳ6, diode chip Ⅴ7 and diode chip Ⅵ8; six cathodes are connected on the copper-clad ceramic substrate, and the cathodes of diode chip Ⅰ3, diode chip Ⅱ4 and diode chip Ⅲ5 are connected through the copper-clad ceramic substrate; six clip copper sheets 9 One end of the diode chip is fixedly connected to the anodes of the six diode chips, and the other ends of the six copper-clad ceramic substrates are fixedly connected to the copper-clad ceramic substrate...

Embodiment 2

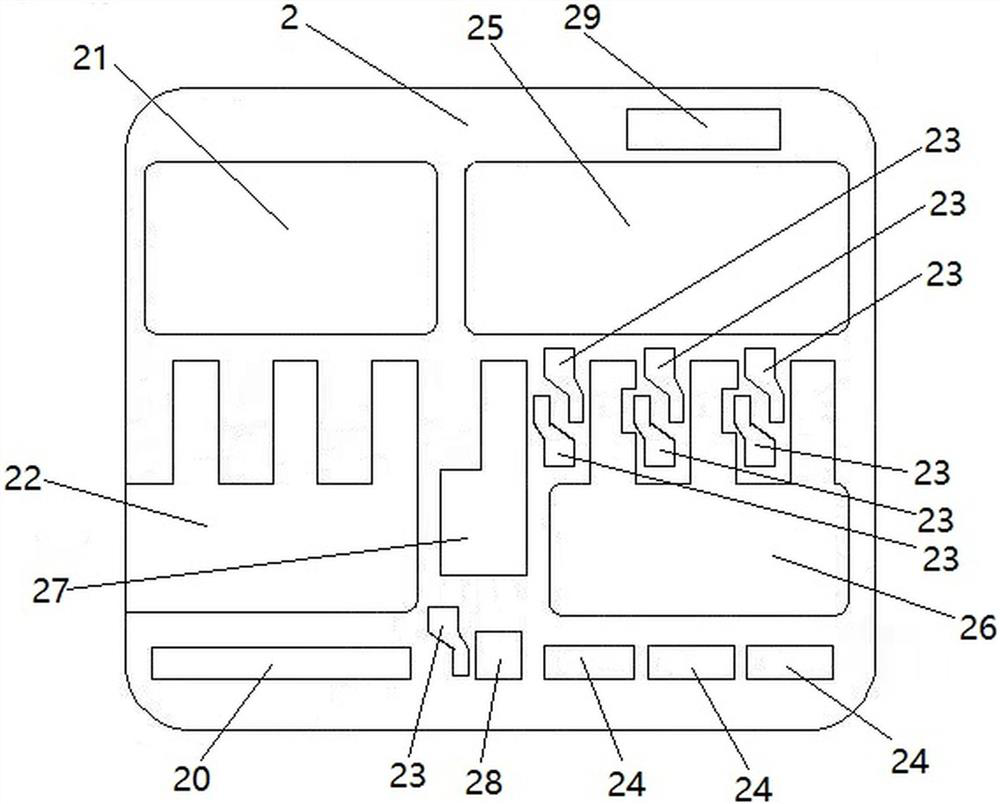

[0054] This embodiment discloses a PIM device, as a preferred implementation of this technical solution, that is, in embodiment 1, the copper-clad ceramic substrate includes a substrate body 2 and is used to connect the three-phase rectifier unit, three-phase inverter The unit, the brake unit and the copper plate unit of the temperature control detection NTC device 1, the copper plate unit is pasted and fixed on the substrate body 2. Specifically, the copper plate unit includes a rectification part and a braking inverter part, wherein the rectification part includes a copper plate I20, a copper plate II21 for arranging a diode chip I3, a diode chip II4 and a diode chip III5, and a copper plate II21 for arranging For the arrangement of diode chip IV6, diode chip V7 and diode chip VI8 copper plate III22; clip copper plate 9 on the positive electrode of diode chip IV6, diode chip IV6, diode chip V7 and diode chip VI8, diode chip I3, diode chip II4 and diode chip III5 The negative...

Embodiment 3

[0056] This embodiment discloses a PIM device, as a preferred implementation of this technical solution, that is, in embodiment 1, IGBT chip I10, IGBT chip II11, IGBT chip III12, IGBT chip IV13, IGBT chip V14 and IGBT chip VI15 Both are composed of IGBT body and freewheeling diode. The three-phase inverter unit of this technical solution adopts an IGBT chip connected in parallel with a freewheeling diode. The IGBT chip will not break down due to the high voltage generated by sudden shutdown, so that the three-phase inverter unit will appear voltage or current in the circuit. It has a protective function when there is a sudden change, and further improves the safety performance of the PIM device.

[0057] Further, all diode chips and IGBT chips are fixed on the copper plate unit by solder paste; all clip copper sheets 9, clip emitter copper sheets 16 and clip control electrode copper sheets 17 are fixed to the copper plate unit by solder paste connection, all clip copper sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com