Optical fiber

A technology of optical fiber and glass optical fiber, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of easy microbending and achieve the effect of less constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

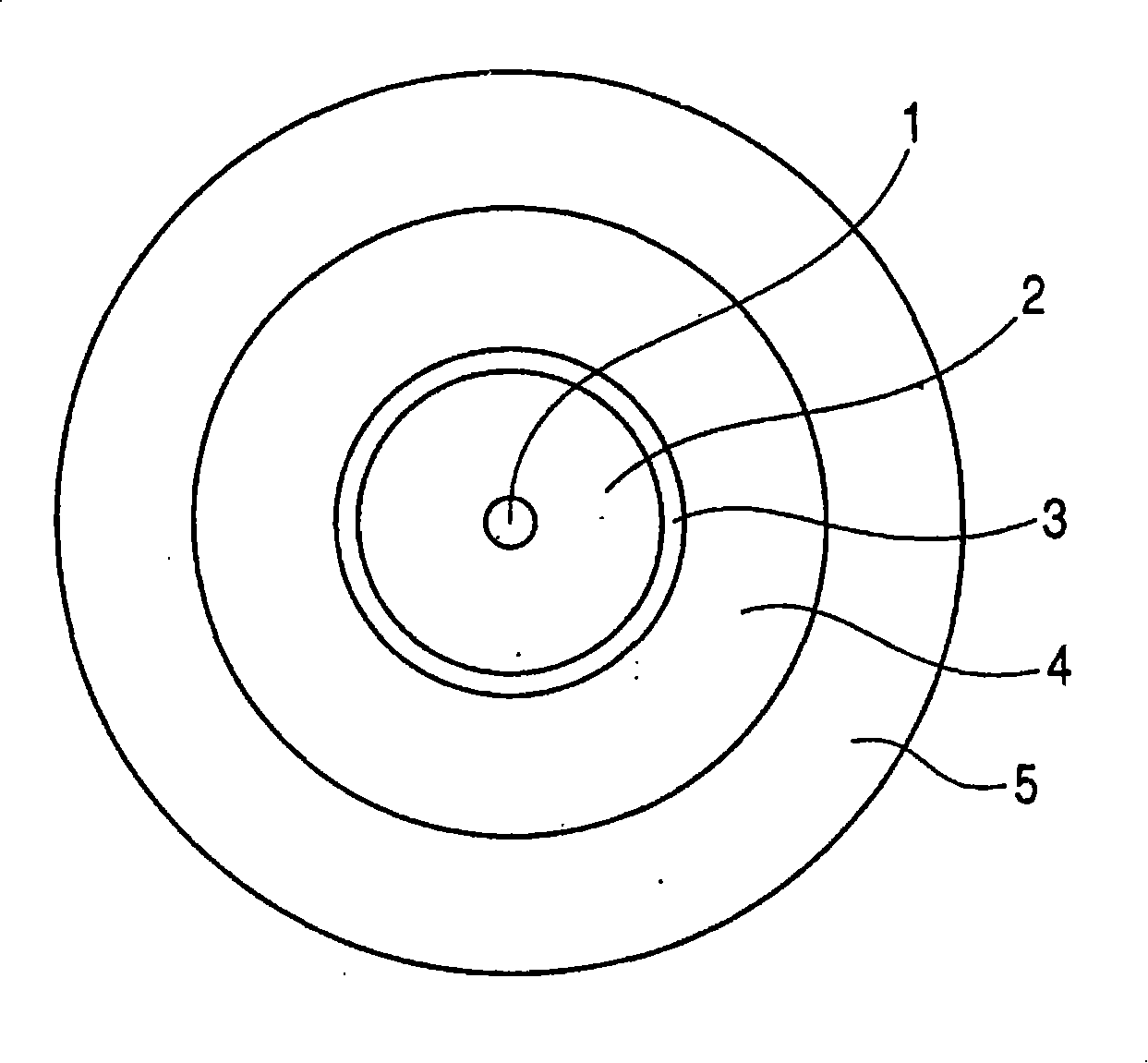

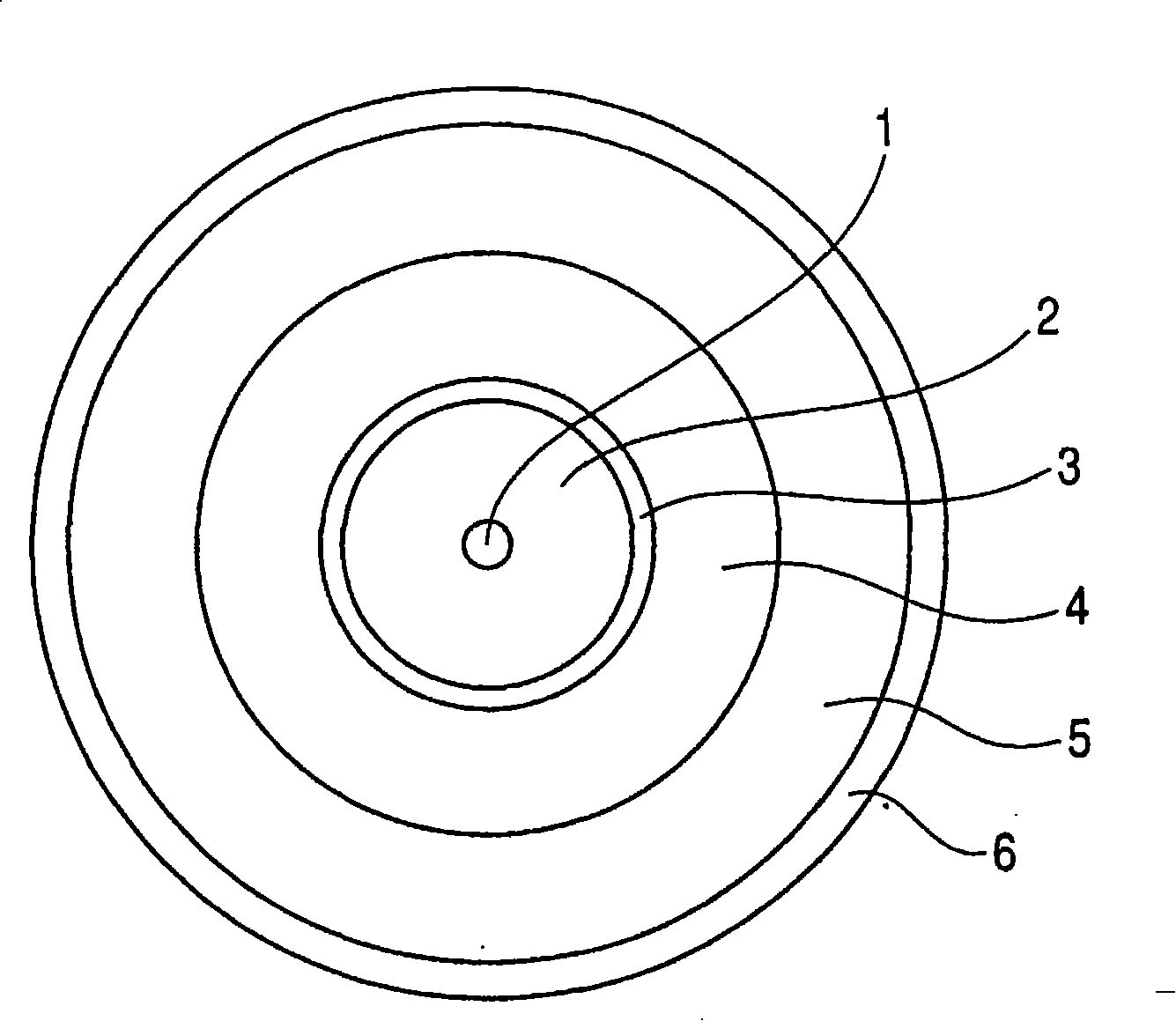

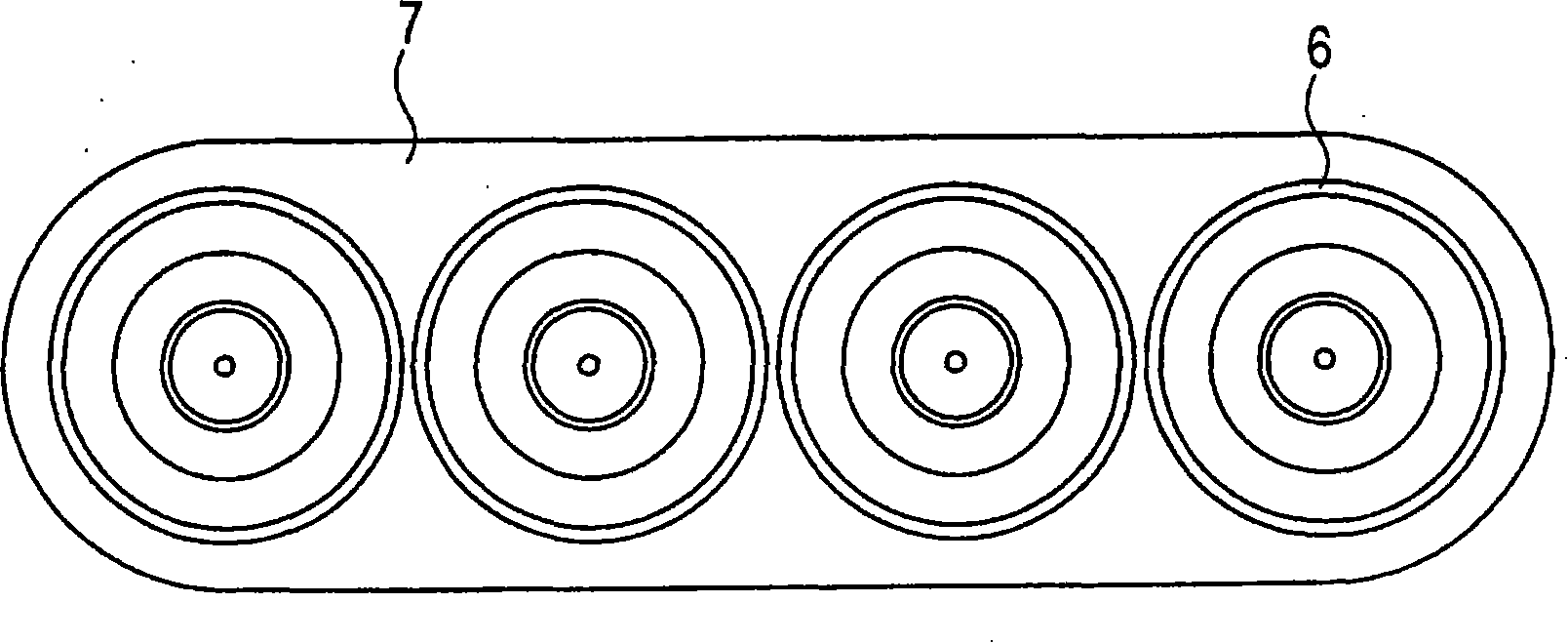

[0038] Next, the optical fiber of the present invention will be described in detail using the drawings.

[0039] figure 1 is a schematic cross-sectional view showing an embodiment of the optical fiber of the present invention. figure 1 The shown optical fiber of the present invention includes: a glass fiber with a core 1 through which optical signals can pass through at the center and a cladding 2 at its periphery; a primary protection layer 3 coated on the glass fiber; formed on the primary protection A secondary protective layer 4 on the layer 3; and a tertiary protective layer 5 further formed on the periphery of the secondary protective layer 4, characterized in that the glass transition temperature Tg of the primary protective layer 3 is greater than -20°C, and at 10°C Hereinafter, the glass transition temperature Tg of the secondary protective layer 4 is 10° C. or lower, and the Tg of the primary protective layer 3 is higher than the Tg of the secondary protective lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com