Multi-stage phase change recycling and storing device of metallurgy high-temperature slag waste heat

A technology of low-temperature phase change and phase change energy storage materials, applied in the field of multi-level phase change recovery and storage devices for metallurgical high-temperature slag waste heat, can solve the problems of ineffective collection and storage of heat, waste of secondary energy, etc., and achieve good Thermal cycle, good recycling and storage, efficient matching and utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

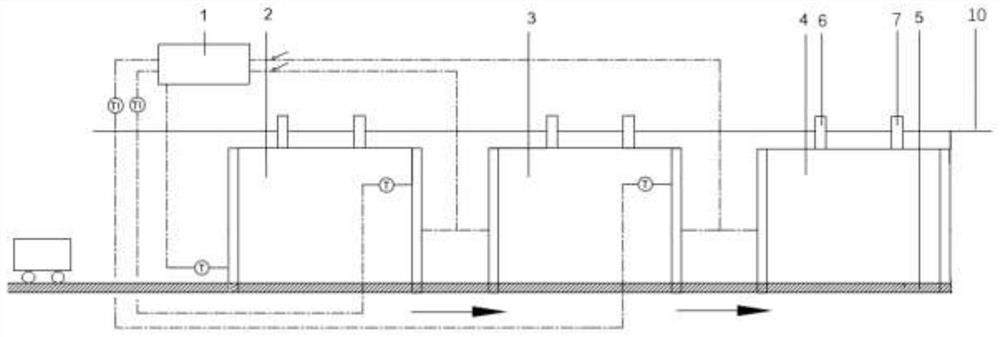

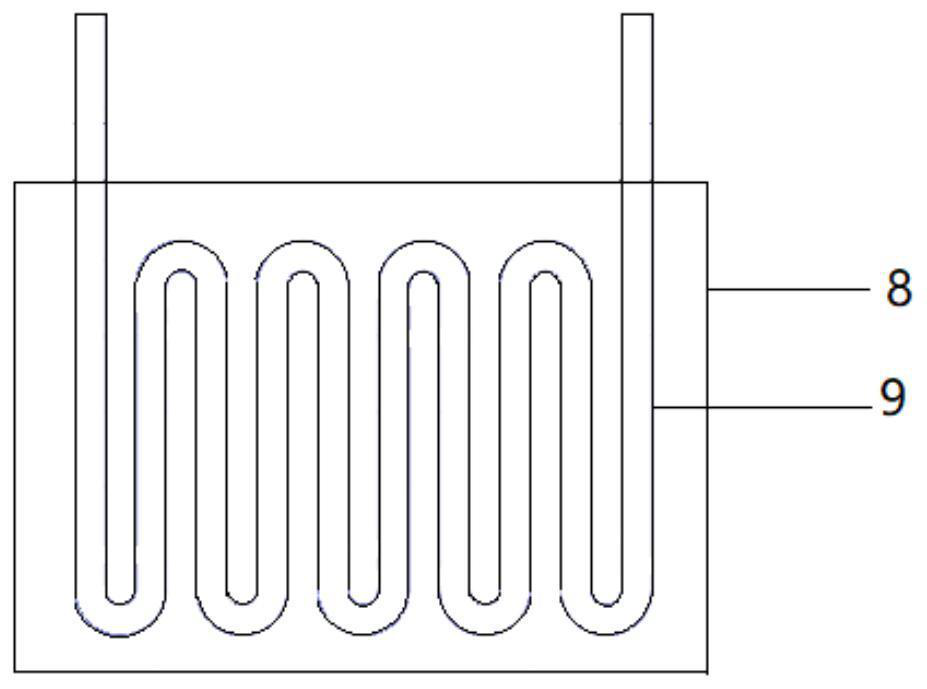

[0049] Such as figure 1As shown, the present invention provides a multi-stage phase change recovery and storage device for metallurgical high-temperature slag waste heat. A medium temperature thermal energy phase change recovery storage unit 3 and a third level low temperature thermal energy phase change recovery storage unit 4; the first level high temperature thermal energy phase change recovery storage unit 2 is equipped with a high temperature phase change energy storage material, and the second level The warm-thermal energy phase change recovery storage unit 3 is equipped with a medium temperature phase change energy storage material, and the third-level low-temperature thermal energy phase change recovery storage unit 4 is equipped with a low-temperature phase change energy storage material; the energy storage unit is recovered through a three-level phase change The heat of different temperatures is recovered sequentially, the heat of metallurgical high-temperature waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com