Two-stage phase change recovery and storage device for metallurgical flue gas waste heat

A flue gas waste heat and phase-change energy storage material technology, which is applied in the field of energy recovery and reuse in the metallurgical industry, can solve the problem of low utilization rate of metallurgical flue gas heat recovery energy, difficulty in utilizing low- and medium-quality waste heat resources, and inability to store heat for backup, etc. problems, to achieve the effect of ensuring maximum recycling, efficient matching utilization, and solving waste problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

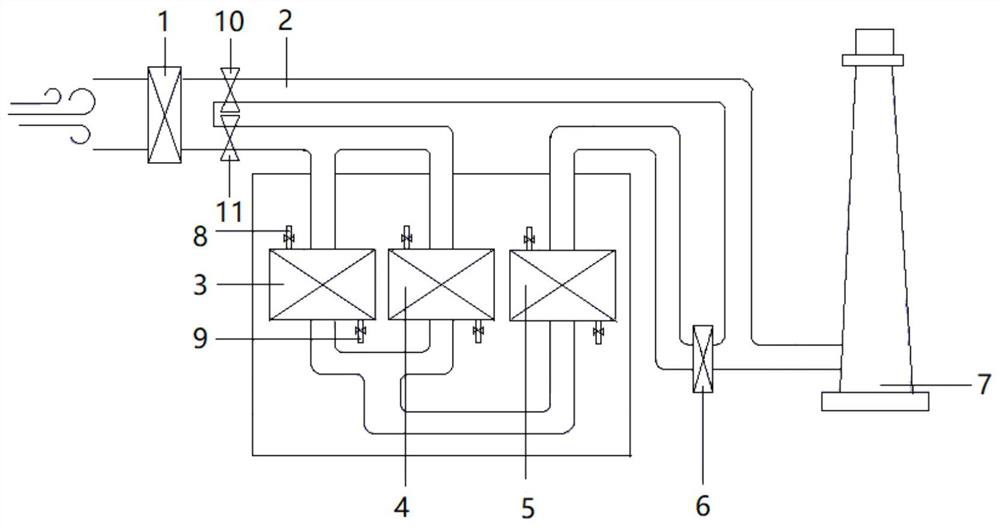

[0070] Such as figure 1 As shown, the present invention provides a two-stage phase change recovery and storage device for waste heat of metallurgical flue gas. unit, the second-stage low-temperature thermal energy phase-change recovery storage unit, exhaust tower 7 and the control system; the metallurgical flue gas inlet section is connected to the end of the metallurgical process that generates high-temperature flue gas; the first-stage medium-temperature thermal energy phase-change recovery storage Phase-change energy storage materials with different phase-change temperatures are installed in the unit and the second-stage low-temperature thermal energy phase-change recovery storage unit;

[0071] The flue gas introduction device 1 quickly introduces metallurgical flue gas into the heat preservation flue gas channel 2 in one direction;

[0072] The thermal insulation flue gas channel 2 is connected to the first-stage medium-temperature thermal energy phase-change recovery st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com