Pipe pile vertical static load testing connection device, and testing system and method using same

A test connection, vertical static load technology, applied in the test of basic structure, construction, basic structure engineering and other directions, can solve the problems of long maintenance time, inapplicability, high requirements, etc. Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

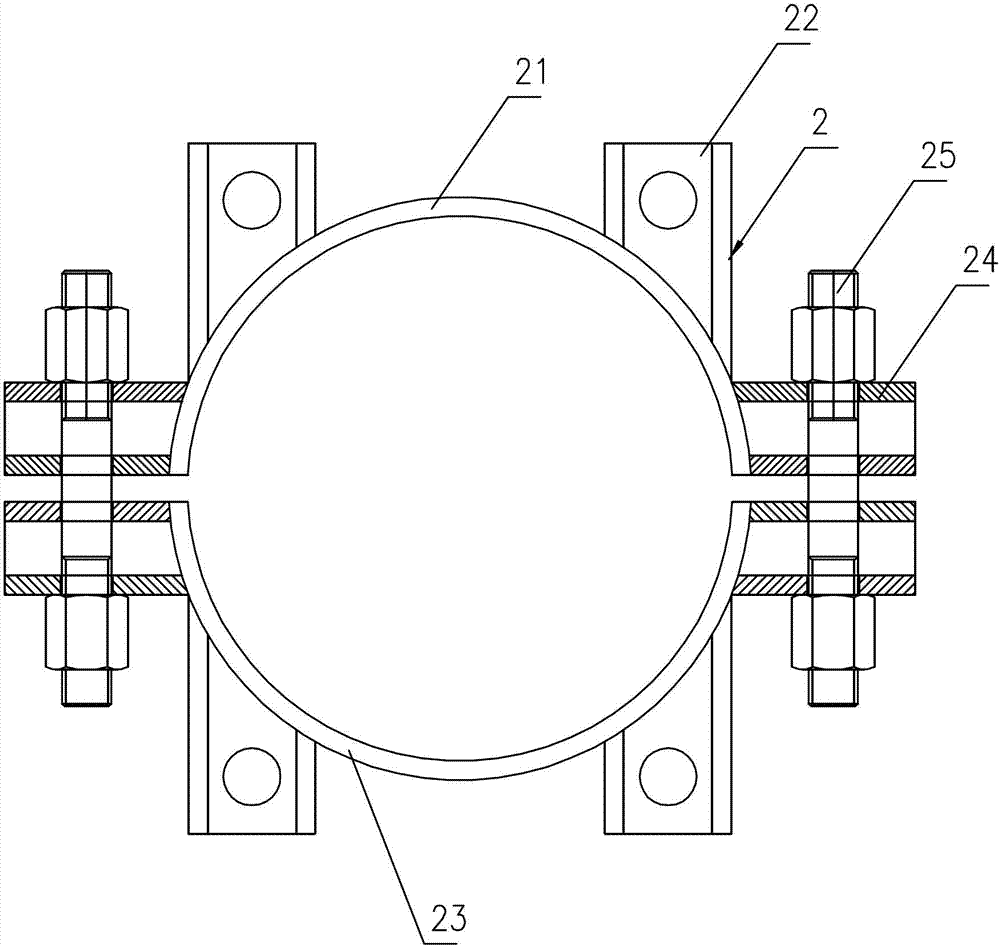

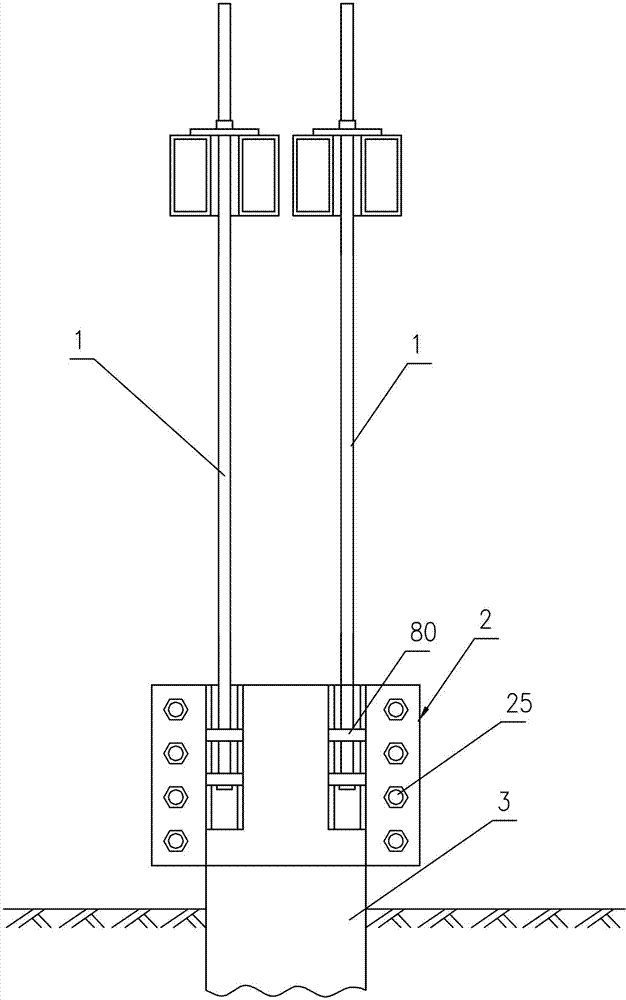

[0053] Such as Figure 1~3 Shown is a pipe pile vertical static load test connection device of the present invention, which is mainly composed of a vertical connecting rod and a clamp 2 for clamping the pile head of the pipe pile. The lower end of the connecting rod 1 is connected to the clamp 2. , The upper end of the connecting rod is used to connect to the loading reaction device located above the pipe pile. The pipe pile is the test pipe pile 3 in the pull-out test. The friction force between the clamp 2 and the test pipe pile 3 will increase The pulling force is transmitted to the test pipe pile 3.

[0054] The connecting rod and the clamp 2 and the loading reaction force device 4 are all connected by a detachable connecting structure. The detachable connection structure is a threaded connection structure. The connecting rod adopts the screw 1, and the clamp 2 is mainly composed of a cylindrical chuck tightly fitted on the test pipe pile and a lug plate 22 arranged on the ou...

Embodiment 2

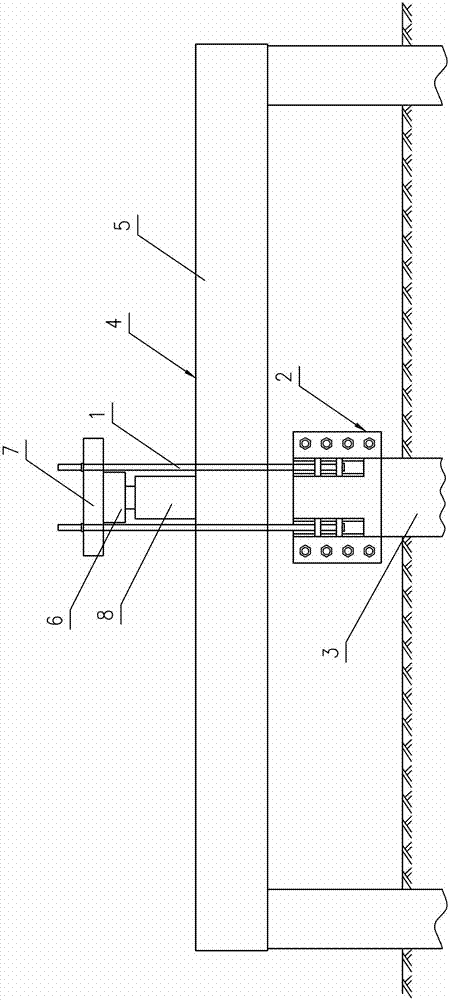

[0065] Such as Figure 4~6 As shown, the difference between this embodiment and embodiment 1 is: the pipe pile vertical static load test connection device is suitable for compression test, the test connection device of the test system of this embodiment connects the anchor pile and the loading reaction device to provide The reaction force acts on the test pipe pile in a balanced manner, and the pipe pile includes the test pipe pile 10 and at least two pairs of anchor piles 11 symmetrically located around the test pipe pile 10.

[0066] The loading reaction device includes a main beam 5, a secondary beam 20, a loading block 60 and a short beam 7. The top surface of the test pipe pile 10 is used to place a jack 8. The main beam 5 spans the test pipe pile 10 and presses on On the jack 8, the secondary beam 20 is positioned directly above the anchor pile 11 in a direction perpendicular to the main beam 5, while the middle part of the secondary beam 20 is pressed on the main beam 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com