Electromagnetic heating element of water heater

A water heater and heating core technology, applied in water heaters, induction heating, fluid heaters, etc., can solve the problems of inability to completely separate electricity and heat, low electrothermal conversion efficiency, and difficulty in ensuring safety, and achieve high electrothermal conversion efficiency. The effect of less flux leakage and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

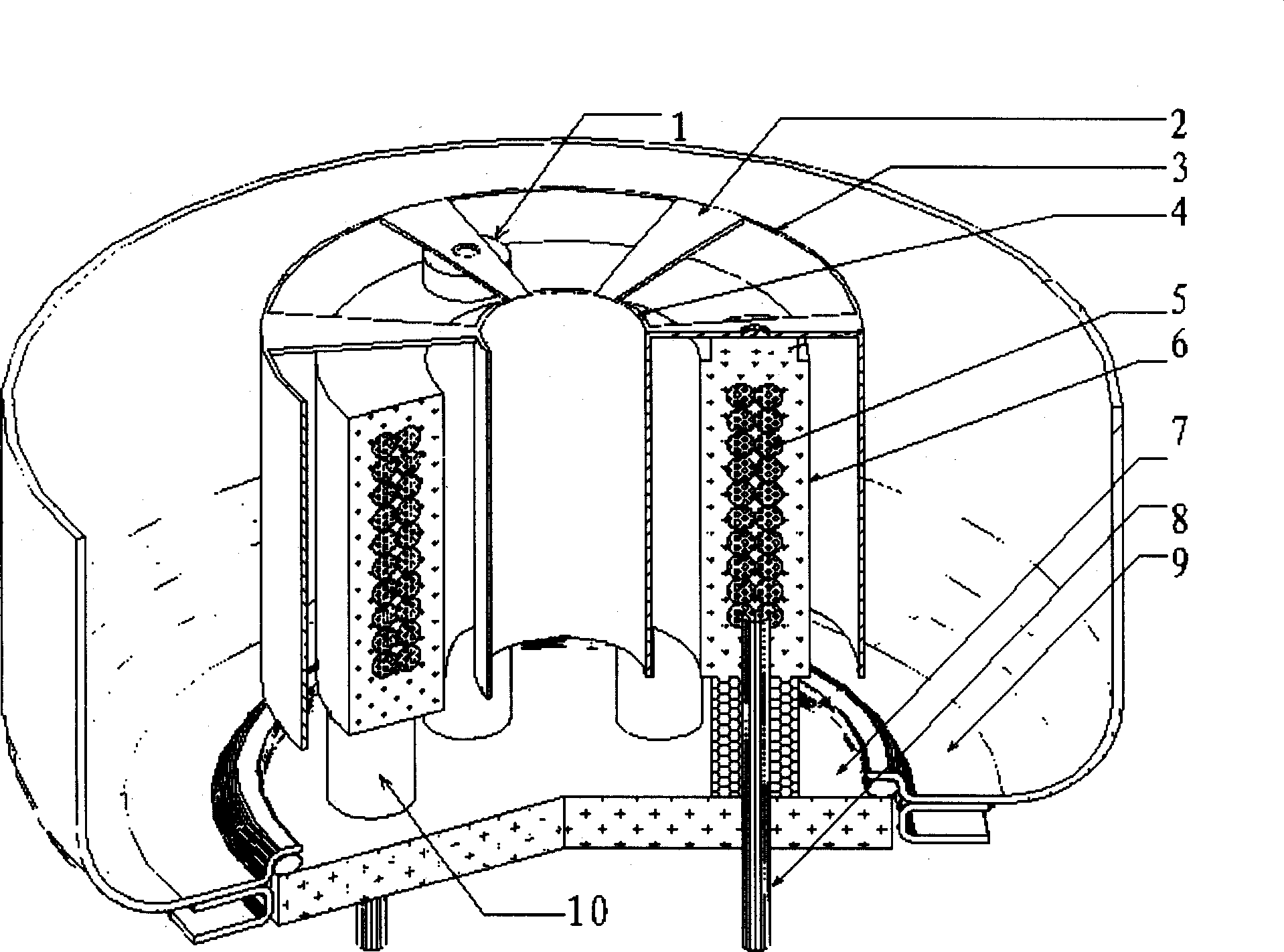

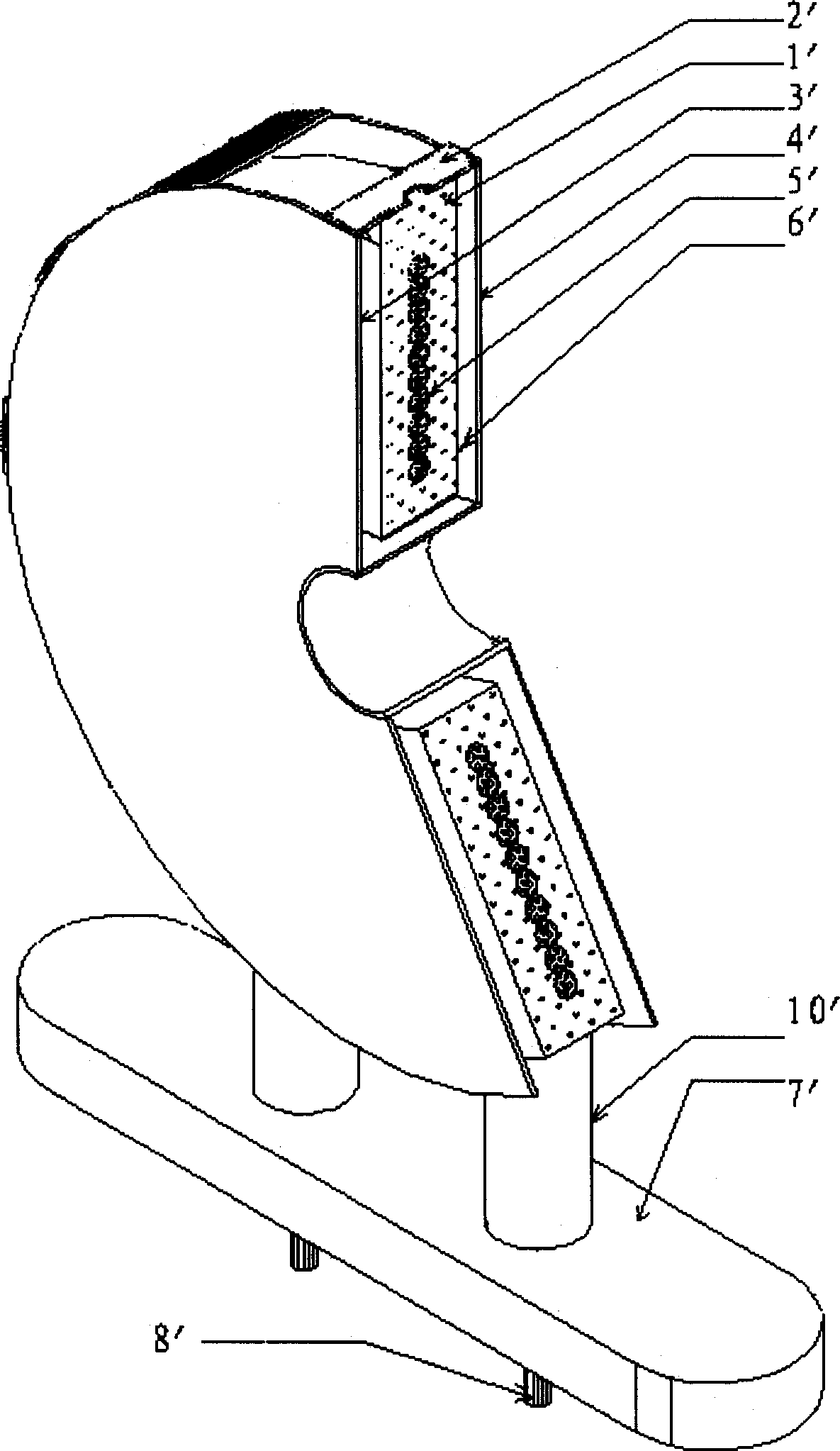

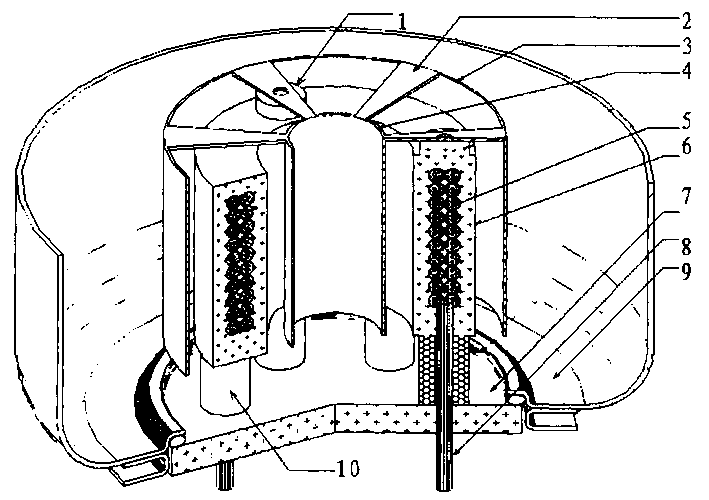

[0008] Embodiment 1 of the present invention is a cylindrical electromagnetic heating core, as shown in FIG. 1 .

[0009] The cylindrical electromagnetic heating core includes an excitation winding and a ferromagnetic heating element. The excitation winding coil 5 is wound into a cylindrical shape, and the whole is sealed in an insulating material that has little influence on the magnetic field lines, has good water permeability resistance, and has a certain heat resistance, forming a cylindrical winding sealing body 6 . There are several insulating and heat-resistant feet 10 separated from each other at the bottom of the winding sealing body 6, and the winding sealing body 6 is fixed and erected on the insulating and heat-resistant base 7. The gap between the bottom of the winding sealing body 6 and the base 7 is 2 ~50 mm. The lead-out wire 8 of the winding 5 is placed under the winding sealing body 6 and placed in certain two legs 10 to seal the lead-out base 7 . There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com