Online thickness monitoring and machining method for large frame and beam part webs

A processing method and parts technology, which is applied in the field of online monitoring and processing of web thickness of large frame and beam parts, can solve problems such as instability, hindering the flexible construction of large frame and beam parts production lines, and increasing production state control, so as to ensure stability , The measurement results are true and reliable, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] This embodiment discloses an on-line monitoring and processing method for the web thickness of a large frame and beam part, as a basic implementation of the present invention, including the following steps:

[0031] S1, establishing a thickness measurement system based on the CNC machine tool 12, mainly because the thickness measurement system needs to be attached to the CNC machine tool 12 for layout, and the thickness measurement system needs to cooperate with the CNC machine tool 12;

[0032] S2, for the large-scale frame and beam parts processed by the CNC machine tool 12, the thickness measuring system is used to perform automatic online measurement of the web thickness of the part; Finished molded parts, which have not been precision trimmed;

[0033] S3, the thickness measurement system calculates the error between the actual part web thickness and the theoretical value based on the measured information, that is, the theoretical value of the tool lift for part we...

Embodiment 2

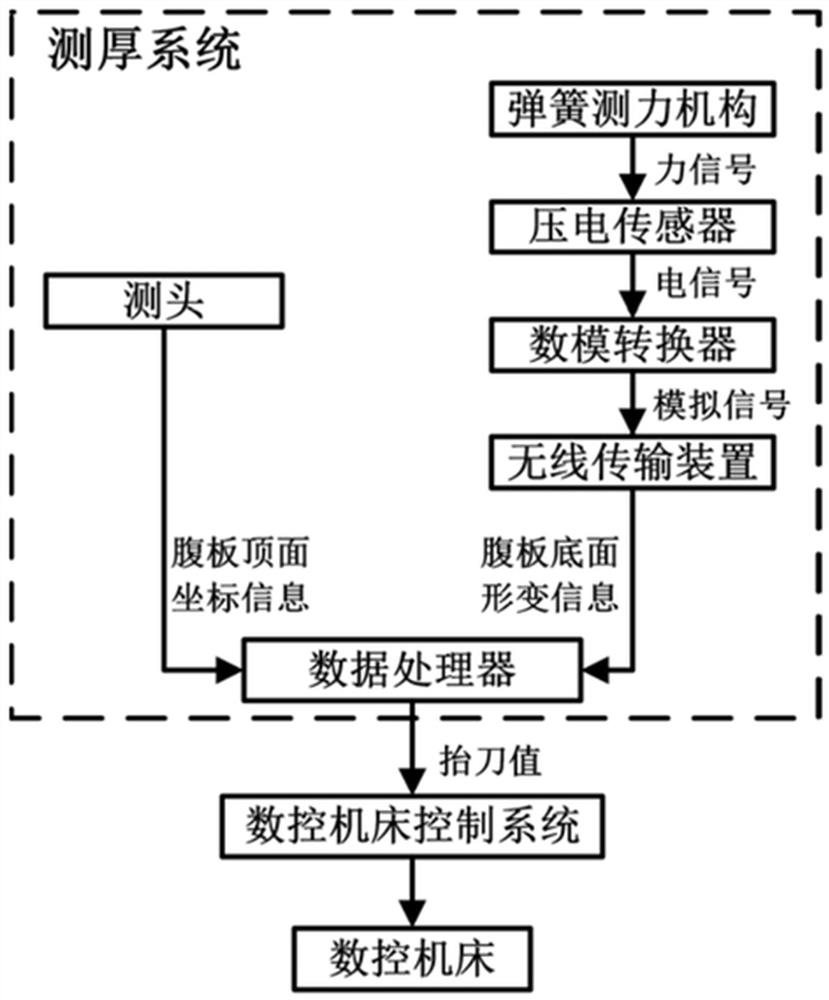

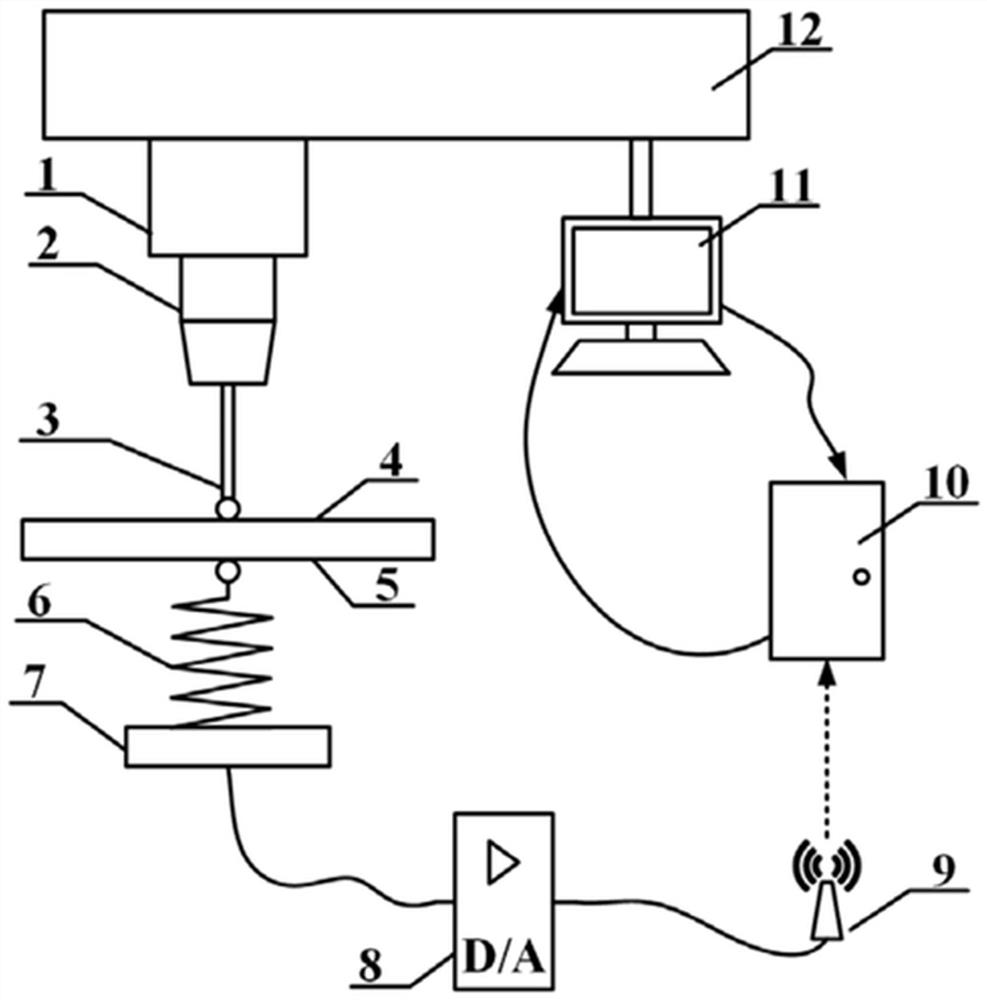

[0038] This example discloses an on-line monitoring and processing method for the web thickness of a large frame and beam part. As a preferred embodiment of the present invention, that is, in step S1 in Example 1, the thickness measuring system includes a measuring head 3, a spring force measuring Mechanism 6, data processor 10, piezoelectric sensor 7, digital-to-analog converter 8 and wireless transmission device 9 electrically connected in sequence, wireless transmission device 9 and data processor 10 are connected in communication, data processor 10 and numerical control machine tool 12 The control system 11 is electrically connected; the measuring head 3 is connected with the spindle 1 of the CNC machine tool 12 through the handle 2 of the CNC machine tool 12 , and the two ends of the spring force measuring mechanism 6 are respectively connected to the lower surface of the web of the part and the piezoelectric sensor 7 .

[0039] In actual use, the measuring head 3 is used ...

Embodiment 3

[0042] This example discloses an online monitoring and processing method for the web thickness of a large frame beam part. As a preferred embodiment of the present invention, based on the thickness measurement system mechanism in Example 2, in step S2, the online monitoring of the web thickness of the part Measurement consists of the following steps:

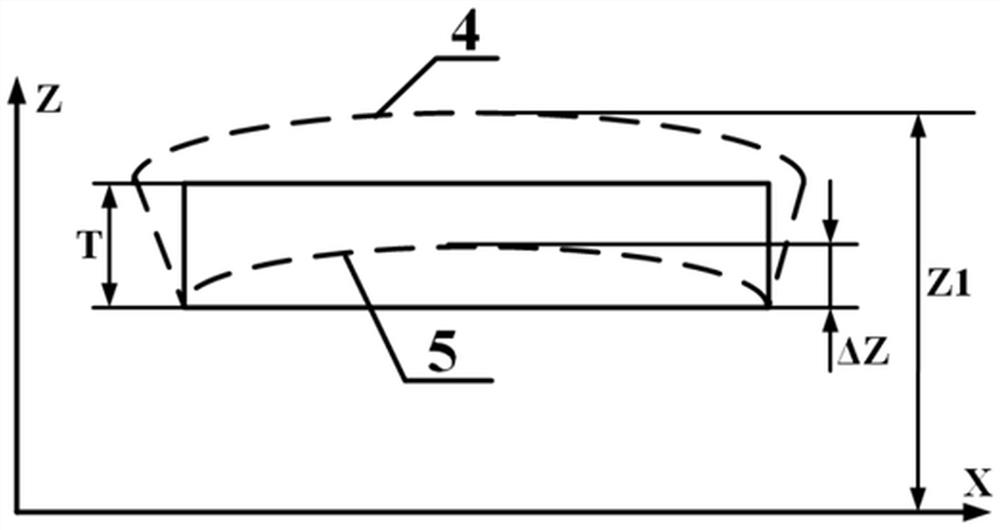

[0043] S21, control the movement of the spindle 1 of the CNC machine tool 12, move the side head to the upper surface 4 of the part web, obtain the coordinate information of the upper surface of the part web through the measurement of the probe 3, and transmit the coordinate information of the upper surface of the part web through the data port Transmission to the data processor 10; wherein, the coordinate information on the upper surface of the part web is measured based on the machining coordinate system of the part web, and the coordinate information is mainly the Z axis (that is, the coordinate axis perpendicular to the CNC m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com