Moving column type numerical control processing centre

A machining center and moving column technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of troublesome cleaning, affecting the accuracy of the machine tool, shortening the service life of the machine tool, etc., so as to prolong the service life and improve the machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

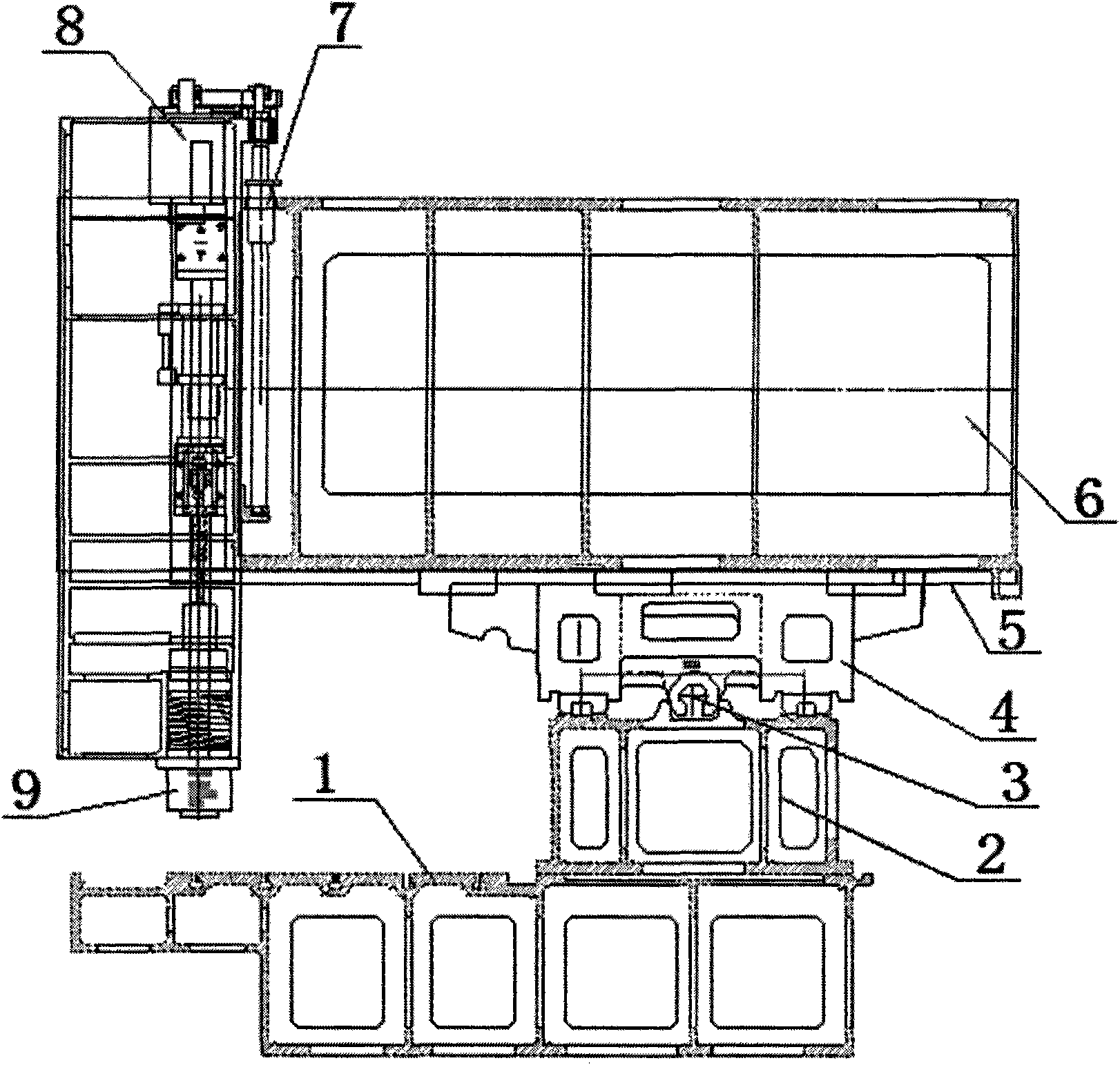

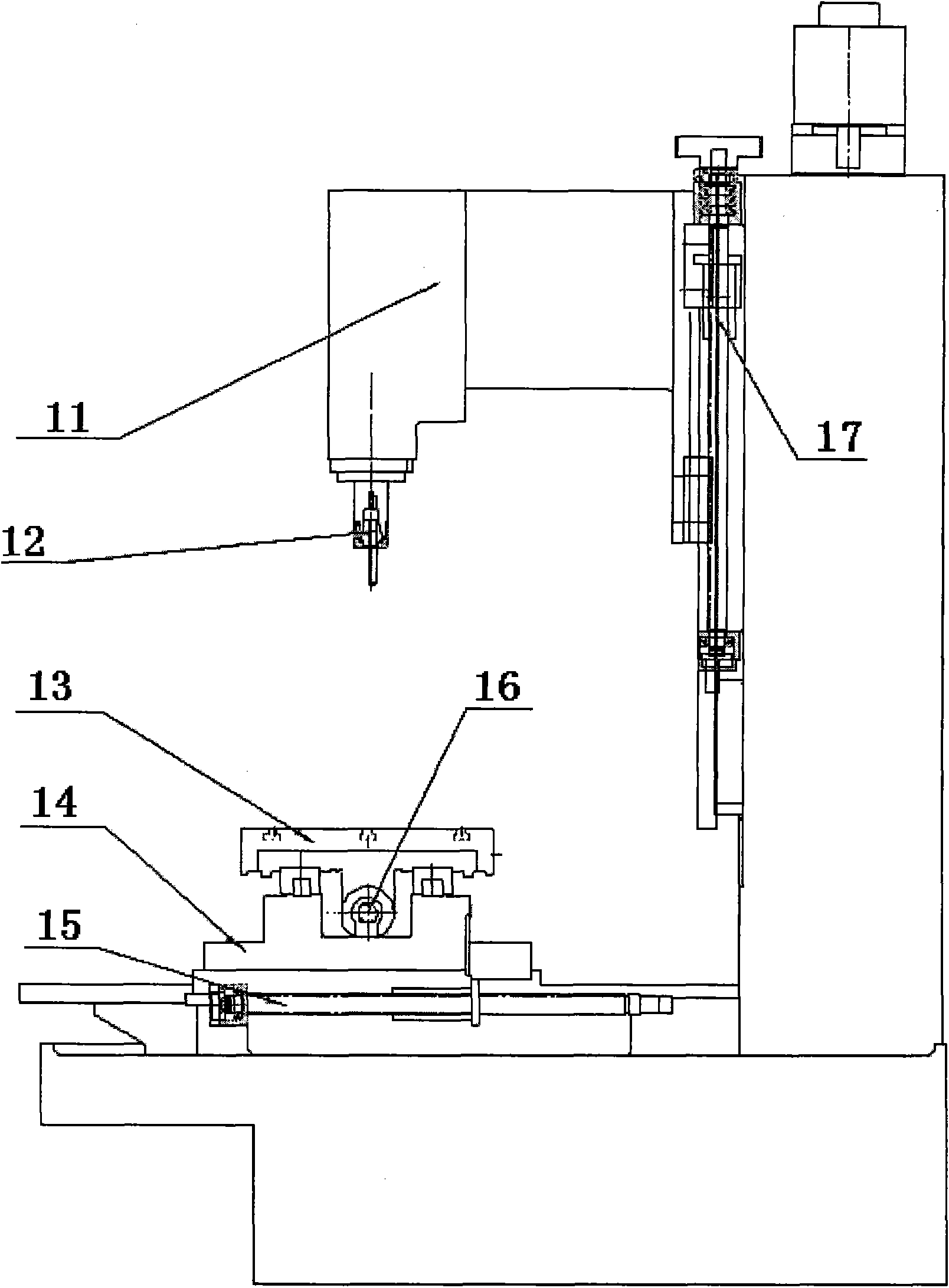

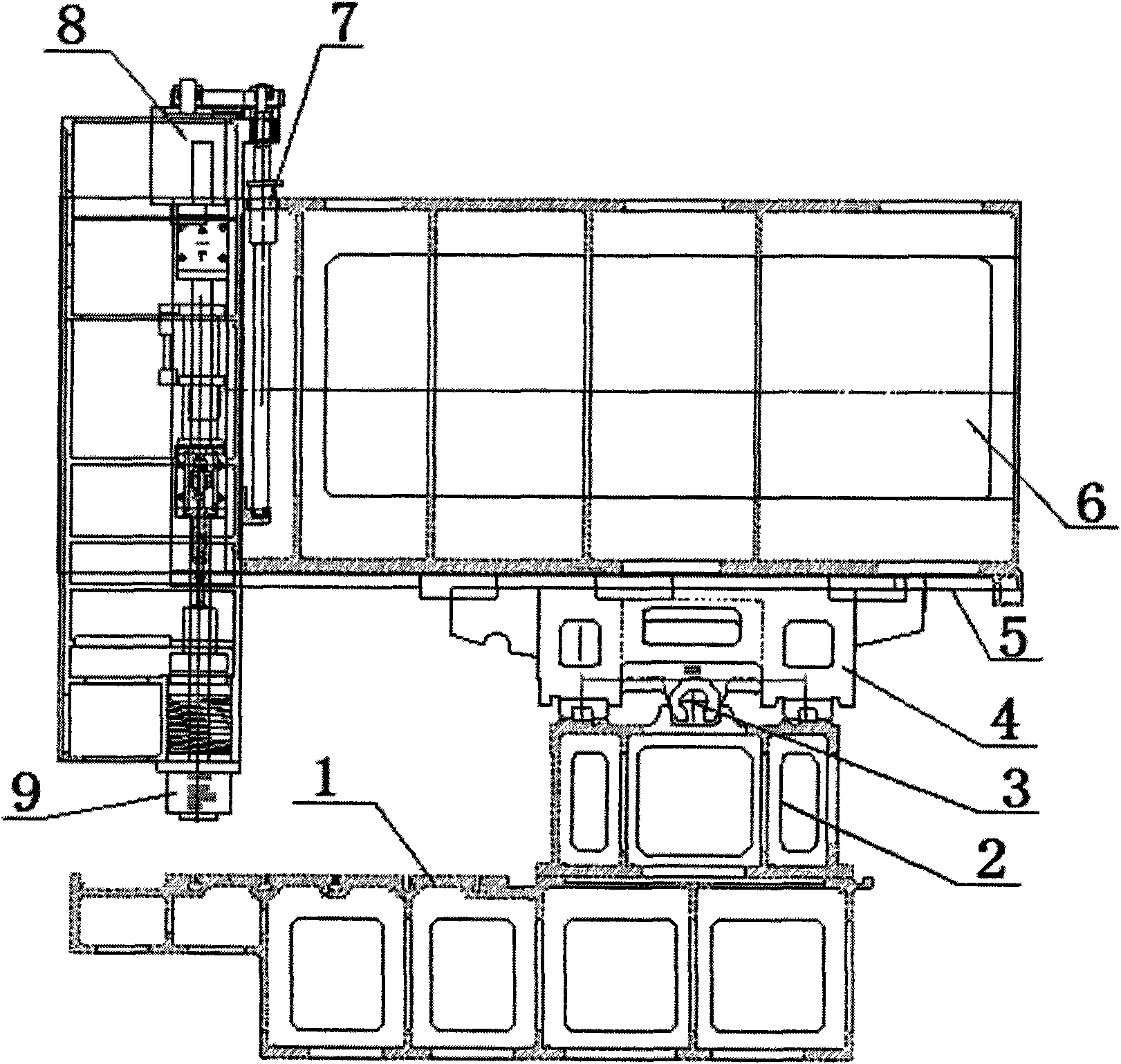

[0012] The reference of moving column type CNC machining center in this embodiment figure 1 , including a workbench 1 for clamping workpieces. A horizontal column 2 is arranged on the workbench 1. A cross slide 4 is connected to the cross column 2 through an X-axis screw rod 3. The upper end of the cross slide 4 is connected to a Y-axis wire. Rod 5, the upper part of the Y-axis screw rod 5 is provided with a longitudinal column 6, one side of the vertical column 6 is connected with a Z-axis screw rod 7, the vertical ram 8 moves up and down through the Z-axis screw rod 7, and the lower end of the vertical ram 8 is connected with a belt Spindle 9 with tool.

[0013] Working principle: The workpiece is statically mounted on the workbench 1, the X-axis screw 3 and the Y-axis screw 5 on the machine tool are installed on the horizontal column 2 at the rear of the machine tool, the Z-axis screw is on the longitudinal column 6, and the motor Drag the cross slide 4 to move on the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com