Clamping control method of three-jaw small roller centering fixture

A control method and centering fixture technology, applied in the direction of the chuck, etc., can solve the problems of restricting the application of the three-jaw small roller centering fixture, complex structure, high cost, etc., achieving simple method, less manual participation, avoiding formula Deduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above features and methods of the present invention more comprehensible, the invention will be further described below with reference to the accompanying drawings and an example.

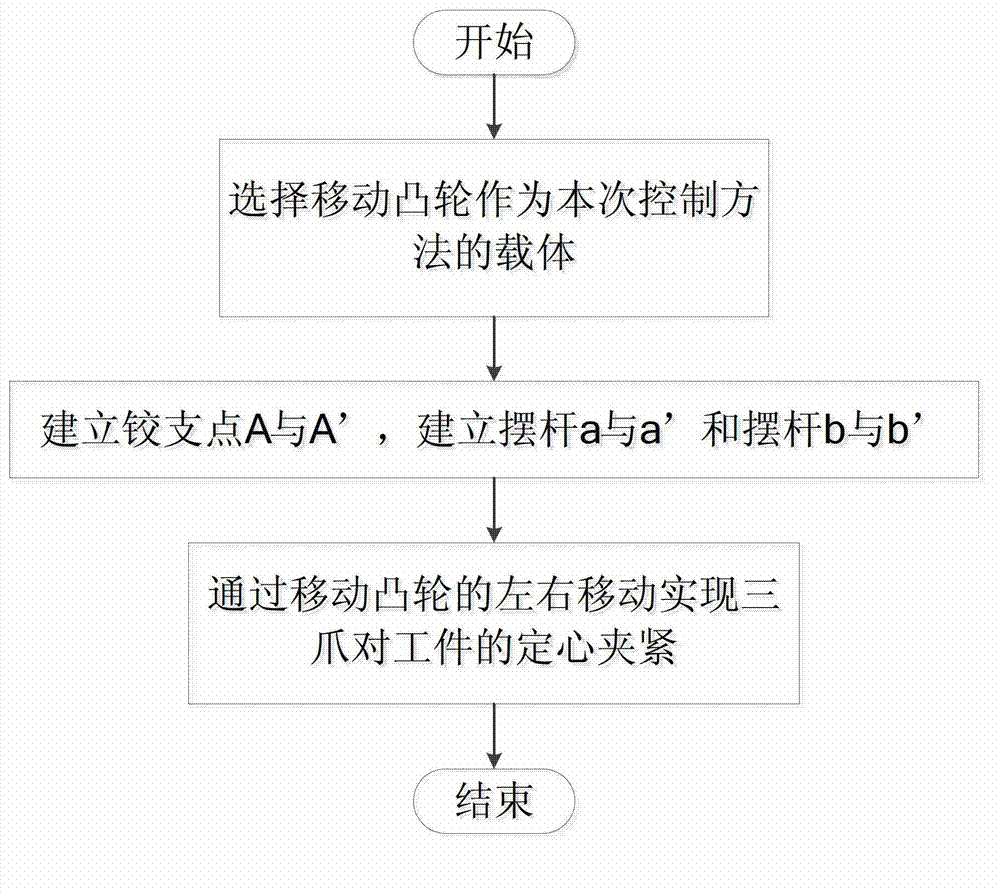

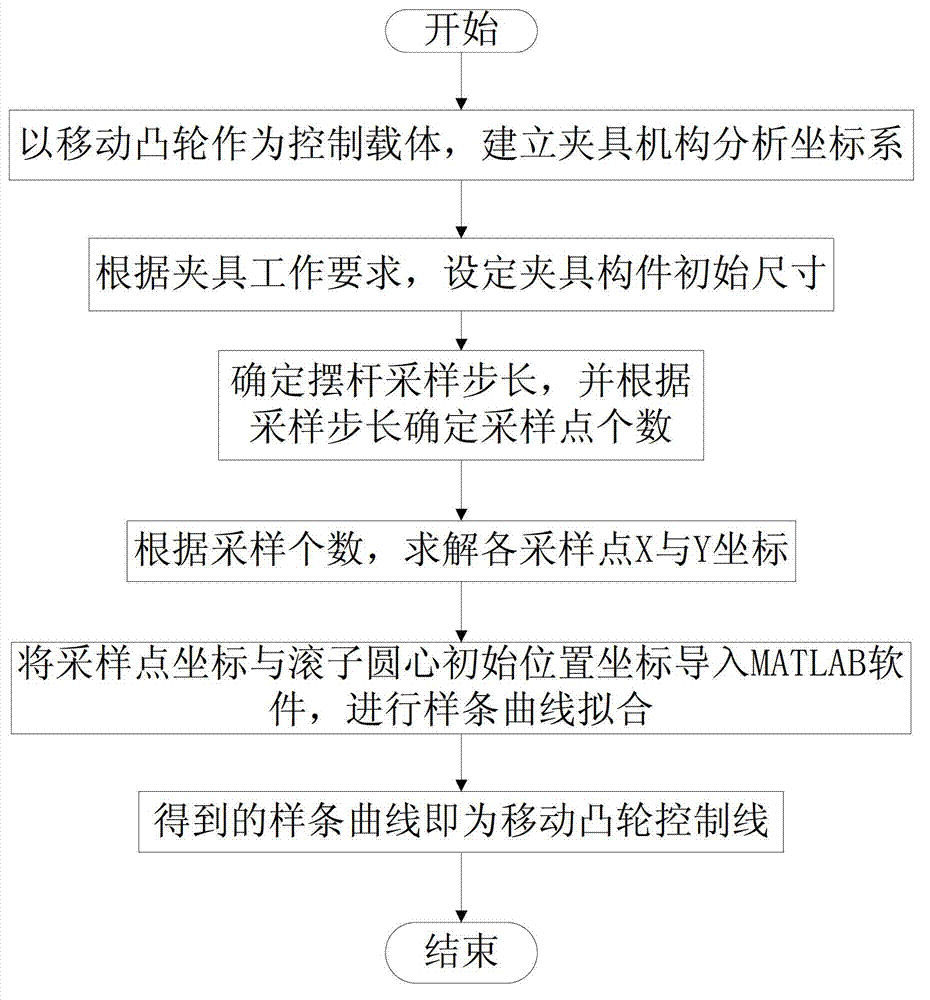

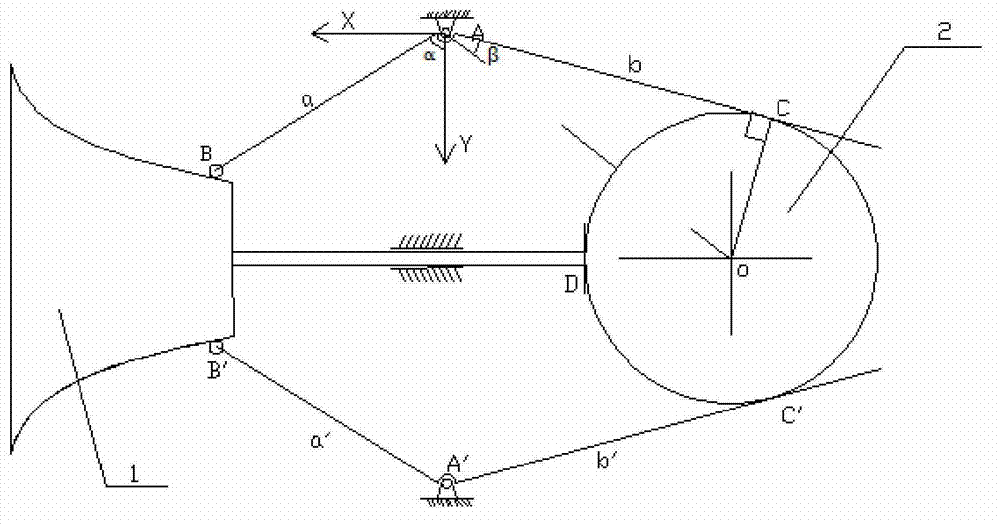

[0025] Such as figure 1 As shown, it is a schematic flow chart of the structural structure of the three-jaw small roller centering fixture of the present invention, combined with image 3 Schematic diagram of the structure of the three-jaw small roller centering fixture. This feature mainly includes the following steps:

[0026] In step 1, the horizontally moving cam 1 is selected as the carrier of the clamping control method. When the clamp is in the initial position, one end of the cam is in contact with the workpiece 2 at the contact point D,

[0027] The fixture described in step 2 is set up using the following method:

[0028] Along the axis of the moving cam as the center line, establish the hinge point A and the hinge point A' in the main section, and the hinge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com