Construction waste crushing and screening machine

A construction waste and screening machine technology, applied in grain processing and other directions, can solve the problems of cumbersome subsequent disposal of waste, and achieve the effect of convenient operation and less manual participation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

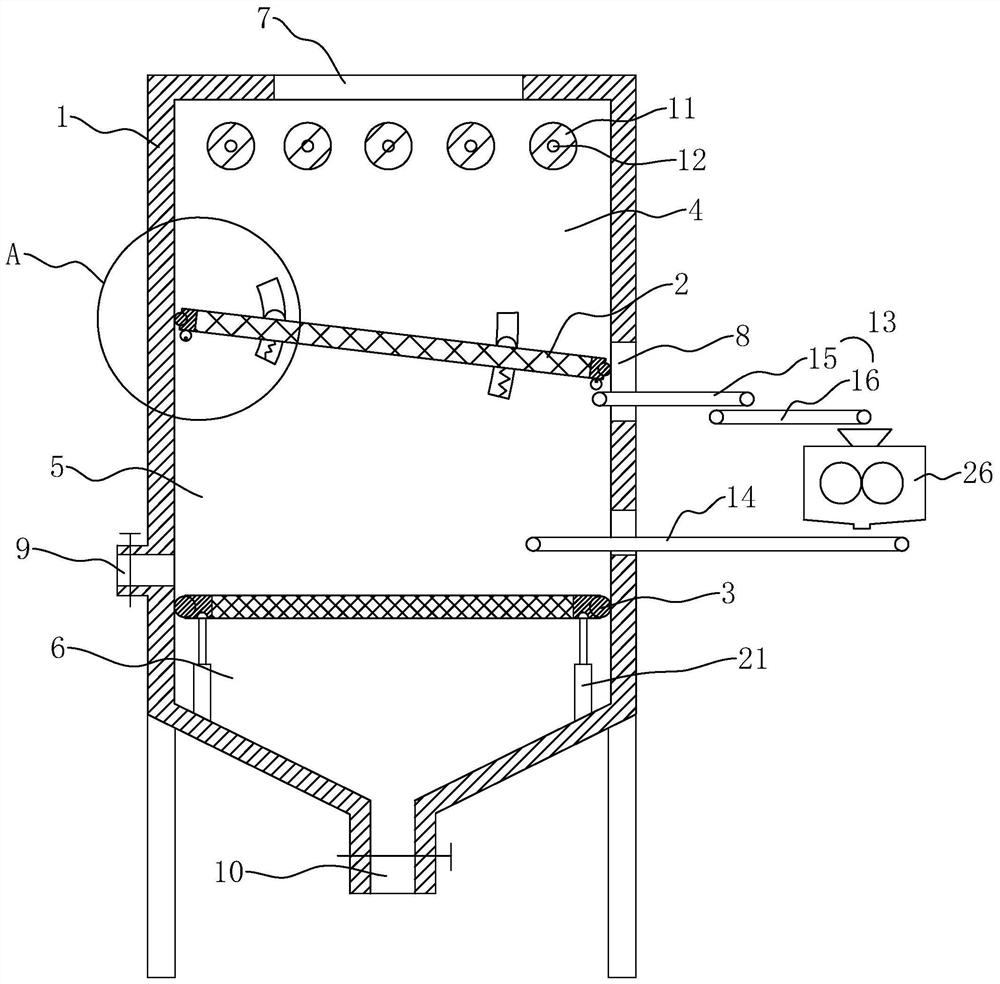

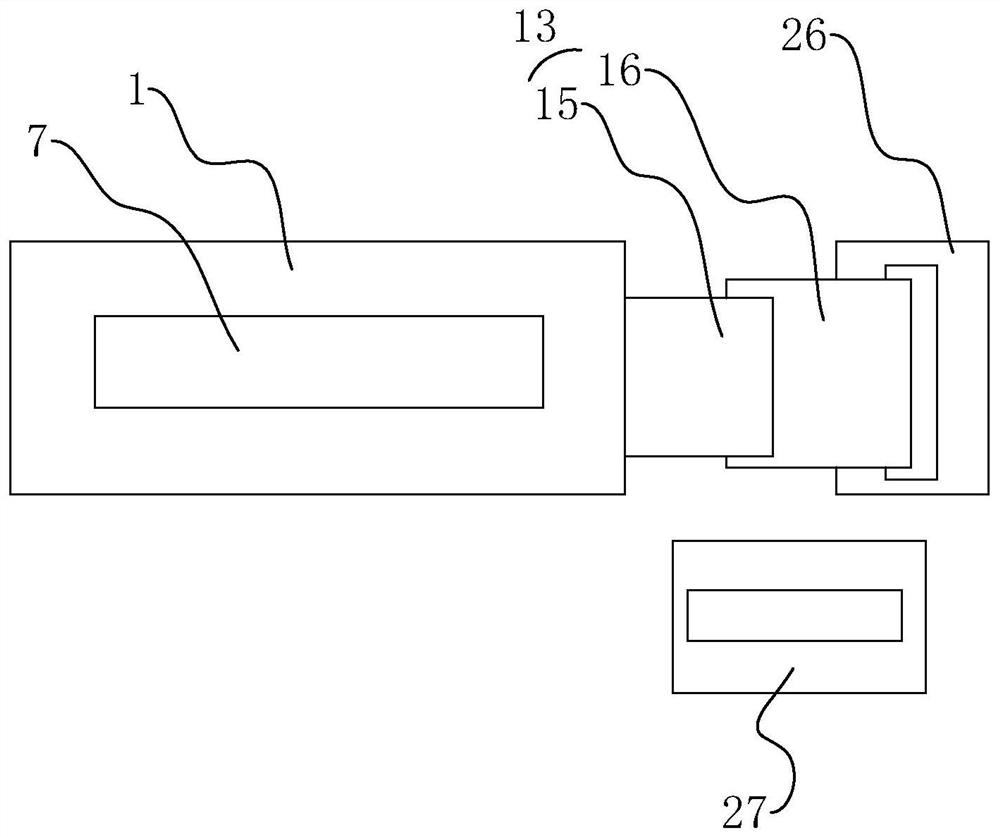

[0038] refer to figure 1 A construction waste crushing and screening machine includes a screening module, a transmission module and a crushing module. The construction waste is transmitted between the screening module and the crushing module through the transmission module, so as to realize the classification and crushing of the construction waste and facilitate the subsequent treatment of the waste.

[0039] Specifically, the screening module includes a screening box 1, and the screening box 1 is sequentially provided with a first screening plate 2 and a second screening plate 3 from top to bottom, and the first screening plate 2 and the second screening plate 3 Divide the screening box 1 into a first material storage chamber 4, a second material storage chamber 5 and a third material storage chamber 6 arranged from top to bottom.

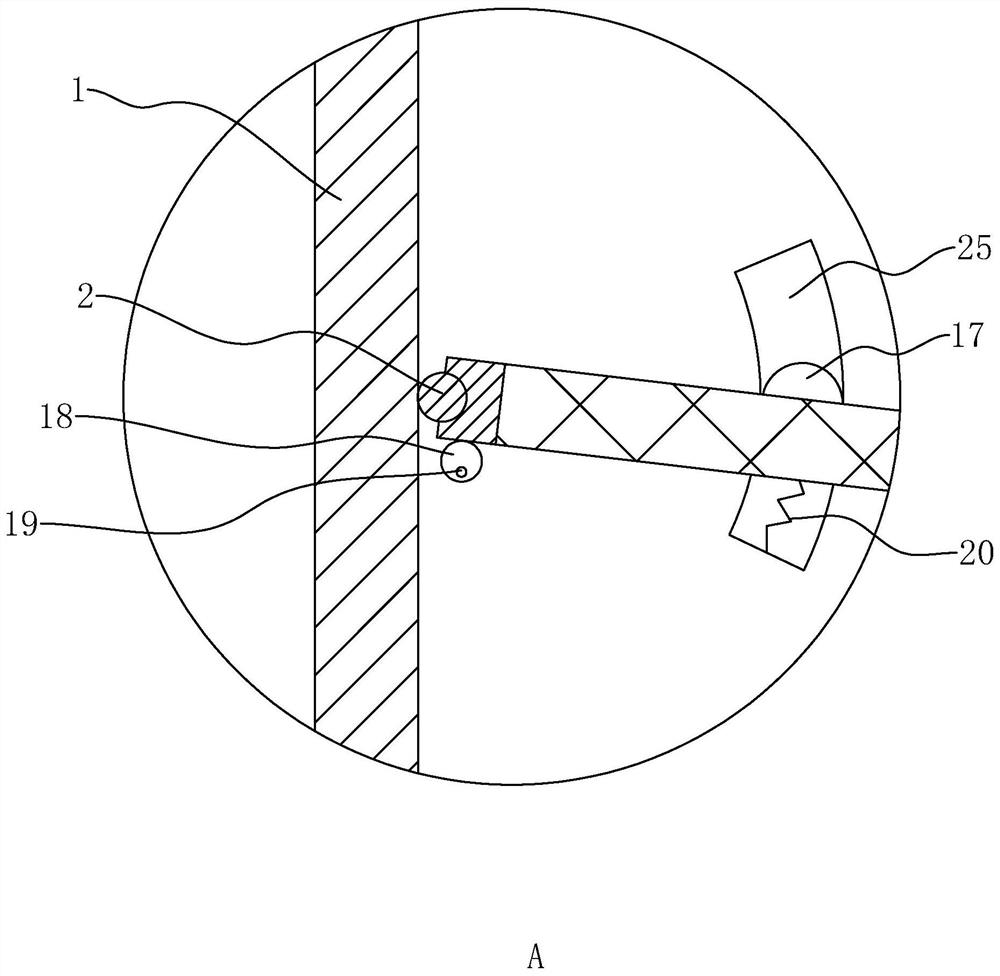

[0040] refer to figure 1 , The upper end of the screening box 1 is provided with a feeding port 7 for feeding. A magnetic attraction mechanism...

Embodiment 2

[0056] refer to Figure 4 , The difference between Embodiment 2 and Embodiment 1 is that the side wall of the screening box 1 is provided with a chain 22 assembly, and the chain 22 assembly is provided with two groups, and is located on the opposite inner wall of the screening box 1 on both sides. The chain 22 assembly includes an endless chain 22 , a sprocket 23 tensioned in the chain 22 and a third driving motor 24 for driving the sprocket 23 to rotate. The electromagnetic rollers 11 are installed on each link of the chain 22 at intervals. The body of the second drive motor 12 is fixedly installed on the chain link, and the output end of the second drive motor 12 is connected to the electromagnetic roller 11 .

[0057] The electromagnetic roller 11 can be driven by the chain 22 to move in the space of the first material storage chamber 4, so that the electromagnetic roller 11 can absorb more metal parts, which facilitates the adsorption of the metal parts and separates them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com