Automatic feeding mechanical hand mechanism for punching machine

A technology of automatic feeding and manipulators, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as low work efficiency and damage to aluminum sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

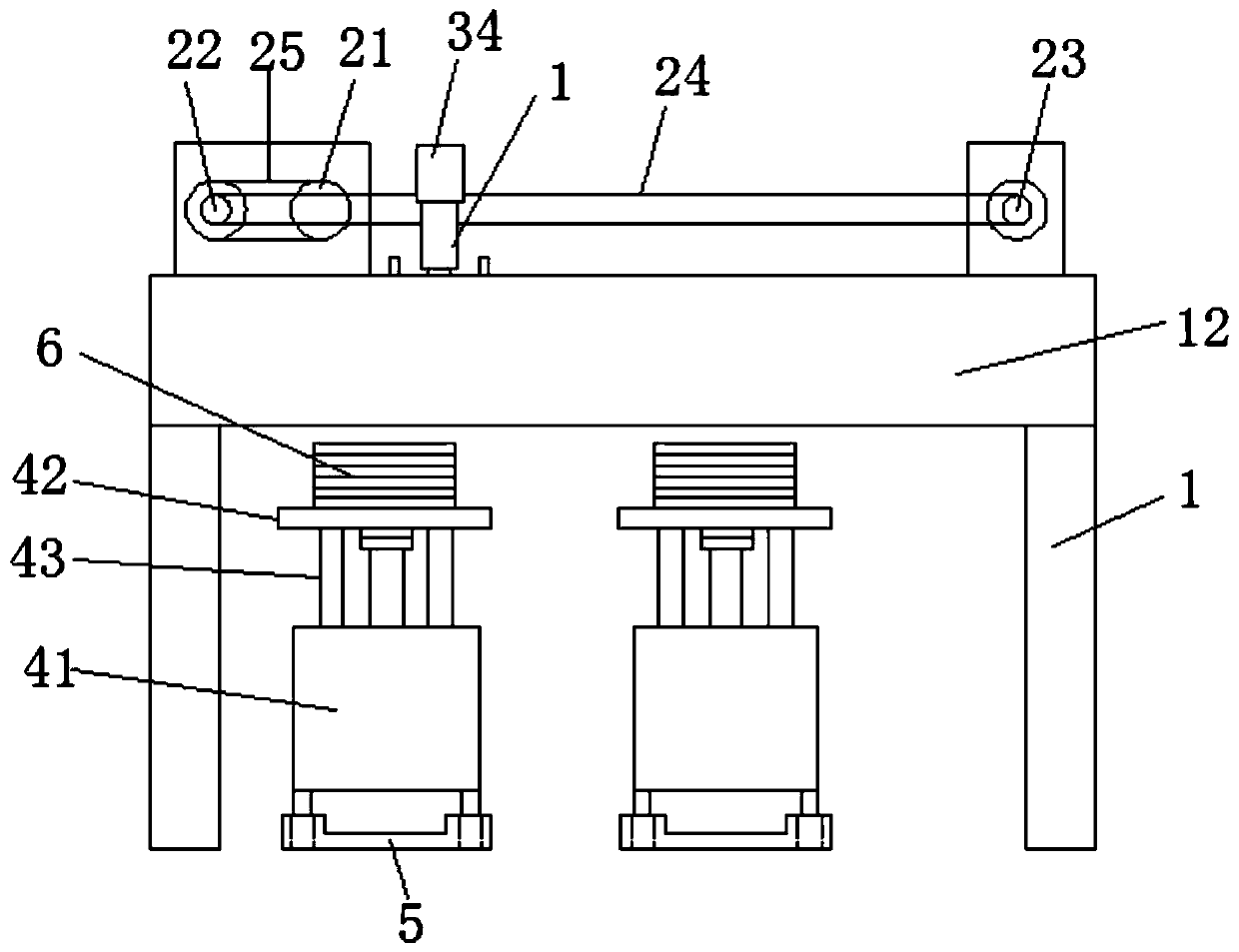

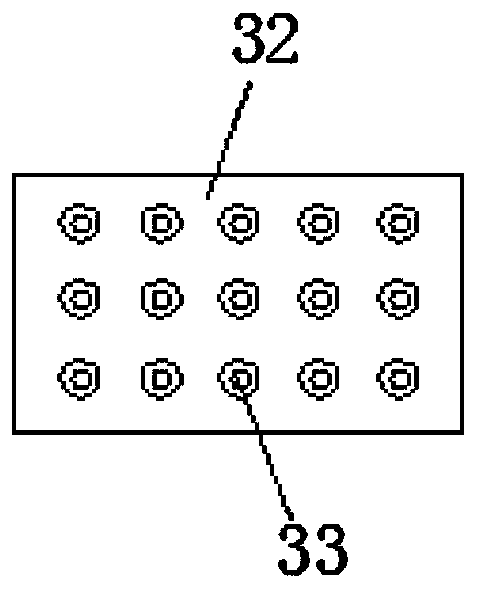

[0020] see Figure 1-4 , the figure shows an automatic feeding manipulator mechanism for a punching machine provided by Embodiment 1 of the present invention, which includes a feeding rack 1, a feeding table located below the feeding rack 1, and a mobile connection to the feeding rack 1. The feeding manipulator includes a linear translation assembly and an up and down lifting assembly. The linear translation assembly includes a drive motor, a drive wheel 21, a driving gear 22, a transmission gear 23, and a chain 24. The drive motor is connected to the drive wheel 21, and the drive wheel 21 passes through the Belt 25 transmission connects driving gear 22, and driving gear 22 connects driven gear 23 by chain 24 transmission; Suction cups 33 evenly distributed, the suction cups are connected to the vacuum generator through the air pipe;

[0021] An automatic feeding manipulator mechanism for a stamping machine provided in this embodiment, the setting of the feeding rack 1 provid...

Embodiment 2

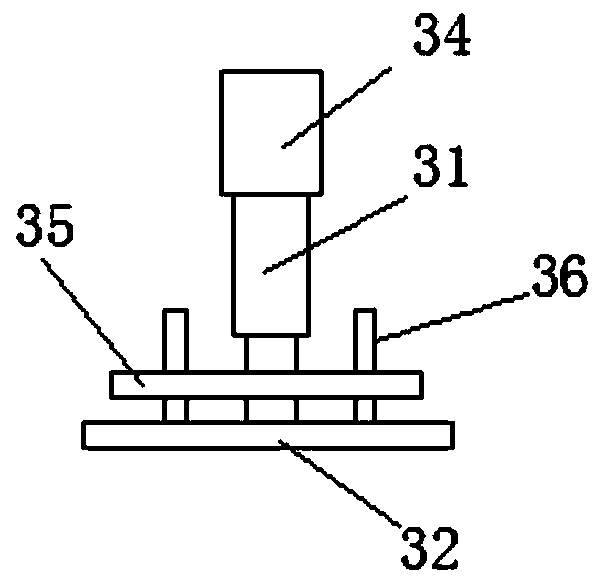

[0023] see Figure 4 , the figure shows an automatic feeding manipulator mechanism for punching machines provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: For the moving direction of the linear translation assembly, a slide rail 11 is provided on the inside of the loading rack 1; a guide plate 35 is provided between the lifting cylinder 31 and the manipulator 32, and the guide plate 35 is slidably connected to the slide rail 11.

[0024] Through the above-mentioned further improvement, this embodiment has the following advantages compared with the prior art: when moving, the guide plate 35 moves along the slide rail 11, which not only has a guiding effect, but also is less likely to be cheap, and improves the feeding accuracy.

Embodiment 3

[0026] see figure 2 , the figure shows an automatic feeding manipulator mechanism for punching machines provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: guide plate A first guide post 36 for guiding is also arranged between 35 and the suction plate.

[0027] Through the above further improvements, this embodiment has the following advantages compared with the prior art: the setting of the first guide post 36 can improve the precision of the up and down movement of the manipulator 32 , thereby improving the feeding precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com