Sludge cleaning equipment for sewage treatment

A technology for cleaning equipment and sewage treatment, which is applied to grain treatment, settling tanks, and feeding/discharging devices of settling tanks. Effects of reducing work costs, preventing clogging of sludge pipes, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

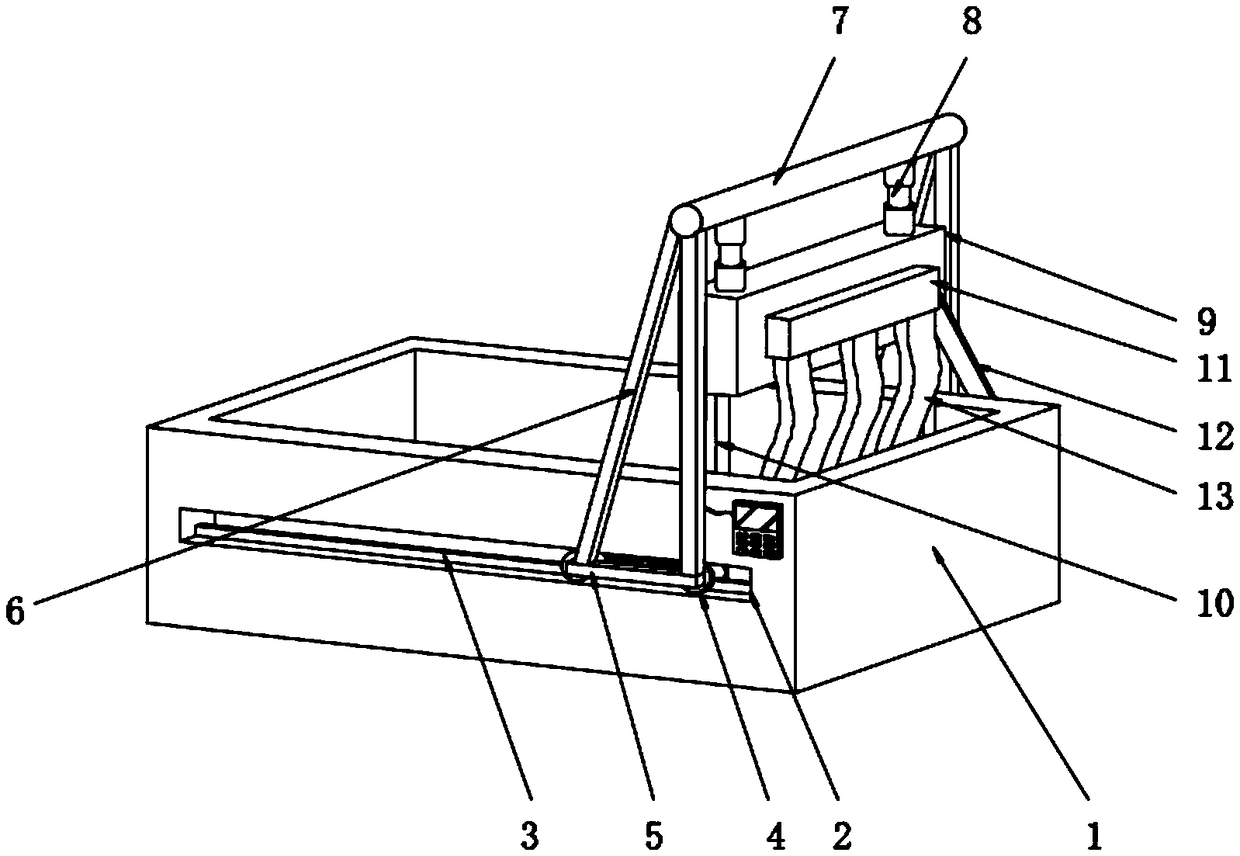

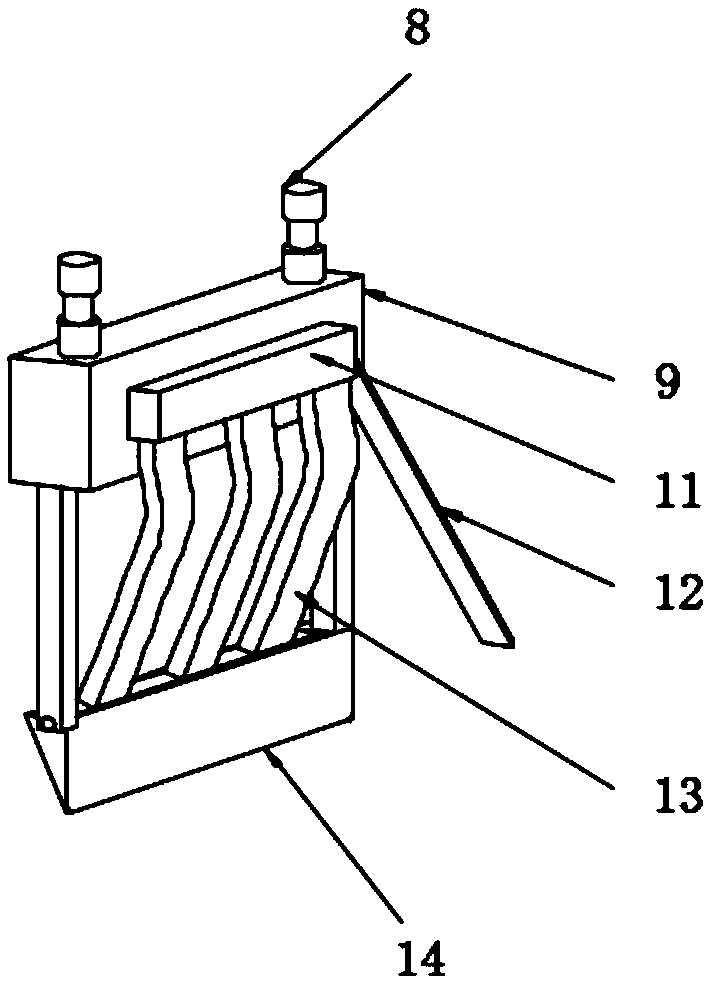

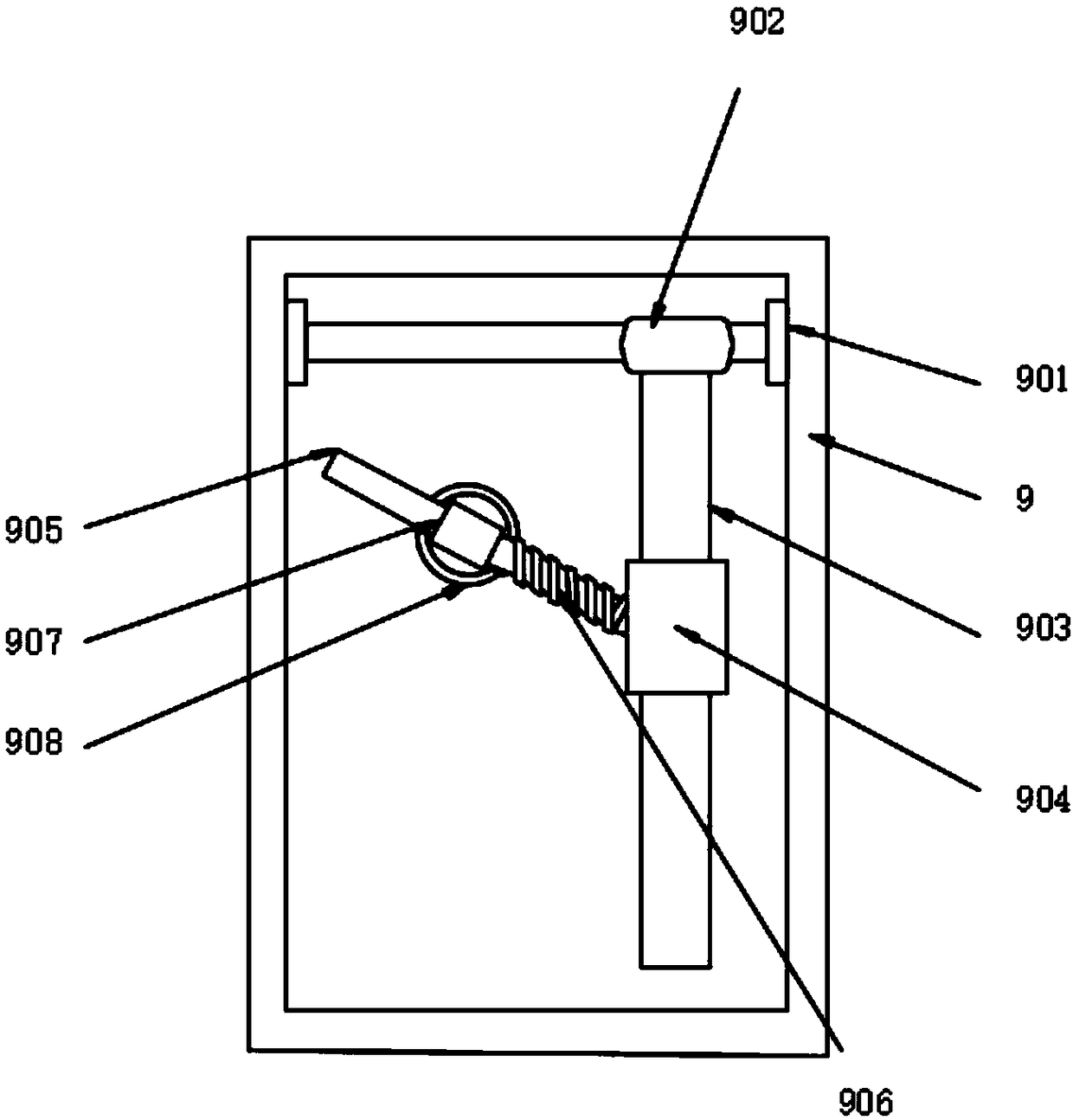

[0028] see Figure 1-2 , in the embodiment of the present invention, a kind of sludge cleaning equipment for sewage treatment comprises a sedimentation tank 1, and both sides of the sedimentation tank 1 are provided with a slide rail groove 2, and the inside of the slide rail groove 2 is fixedly equipped with a partition 3, and the sliding The inside of the rail groove 2 is equipped with pulleys 4 near the two sides of the partition plate 3. The pulley 4 is stuck on the outside of the partition plate 3 to prevent the pulley 4 from falling off from the slide rail groove 2, and the partition plate 3 allows the pulley 4 to move along the fixed The route is forward or backward, and the outer side of the pulley 4 is fixedly installed with a mounting plate 5, and the driving motor of the mounting plate 5 is connected with the pulley 4, which can automatically change the working place of the sludge cleaning equipment. The upper surface of the mounting plate 5 is fixedly mounted with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com