Cantilever force-bearing frame and mounting method thereof

A load-bearing frame and overhanging technology, applied in the field of load-bearing frames, can solve problems such as consuming a lot of time and energy, and achieve the effects of reducing possibilities, increasing installation stability, and reducing labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

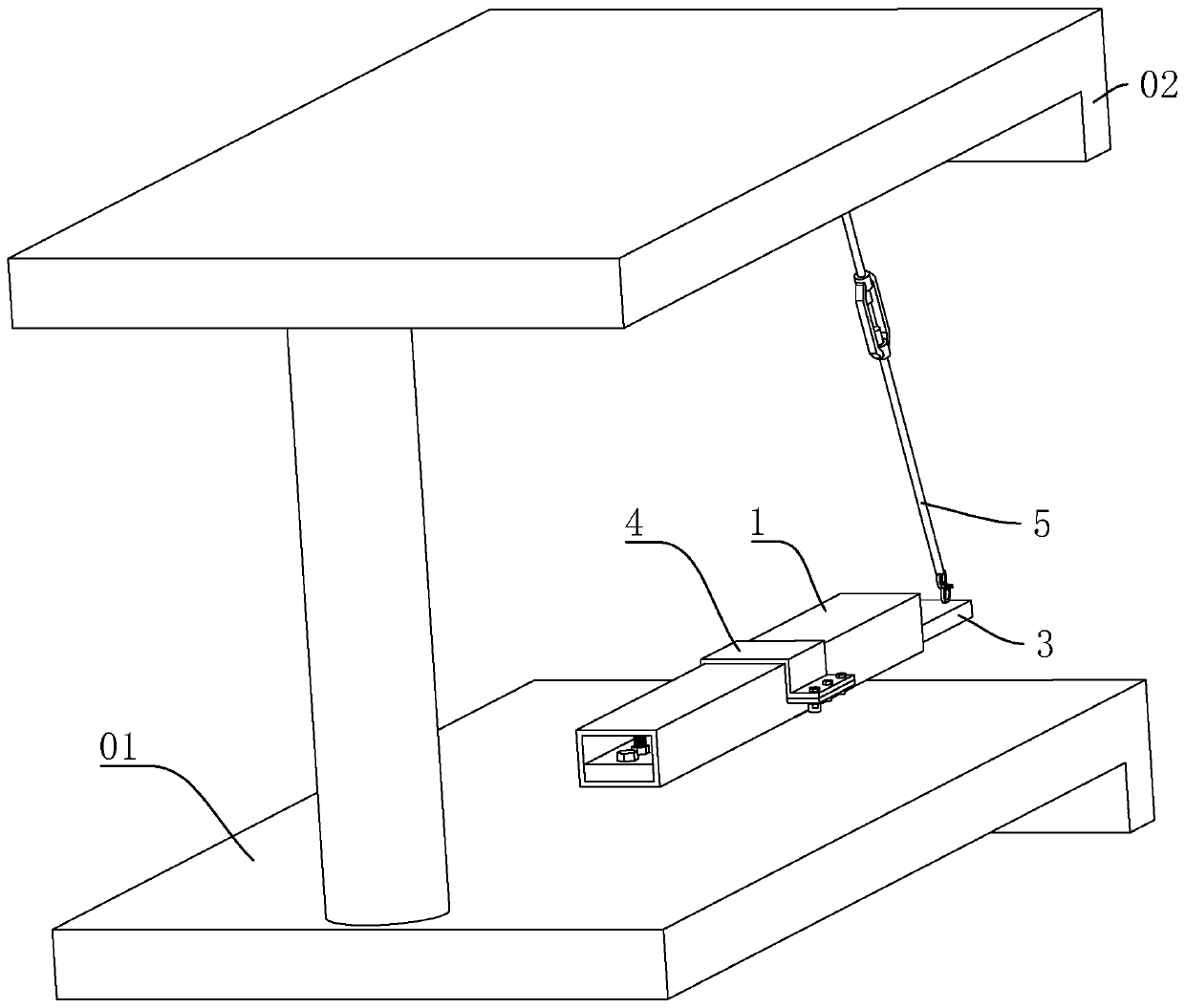

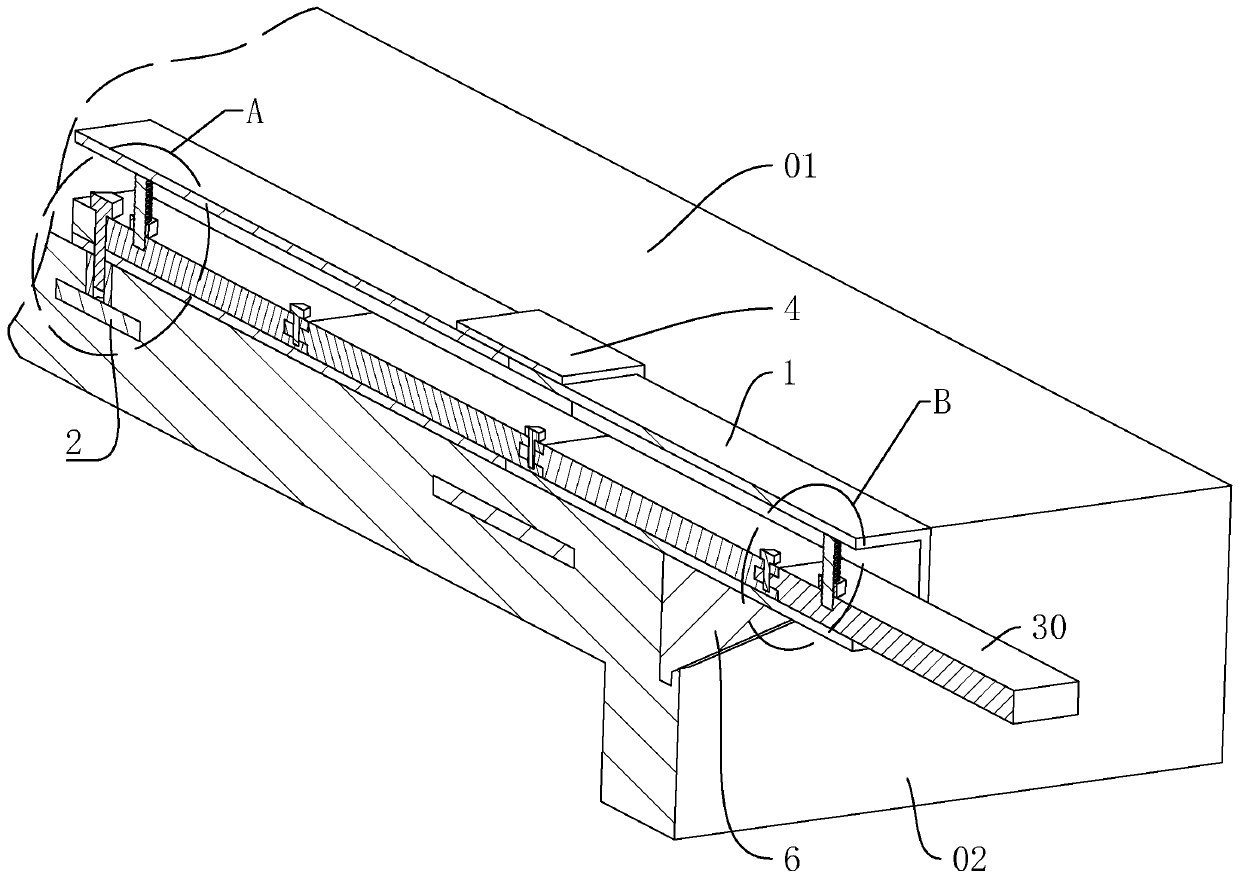

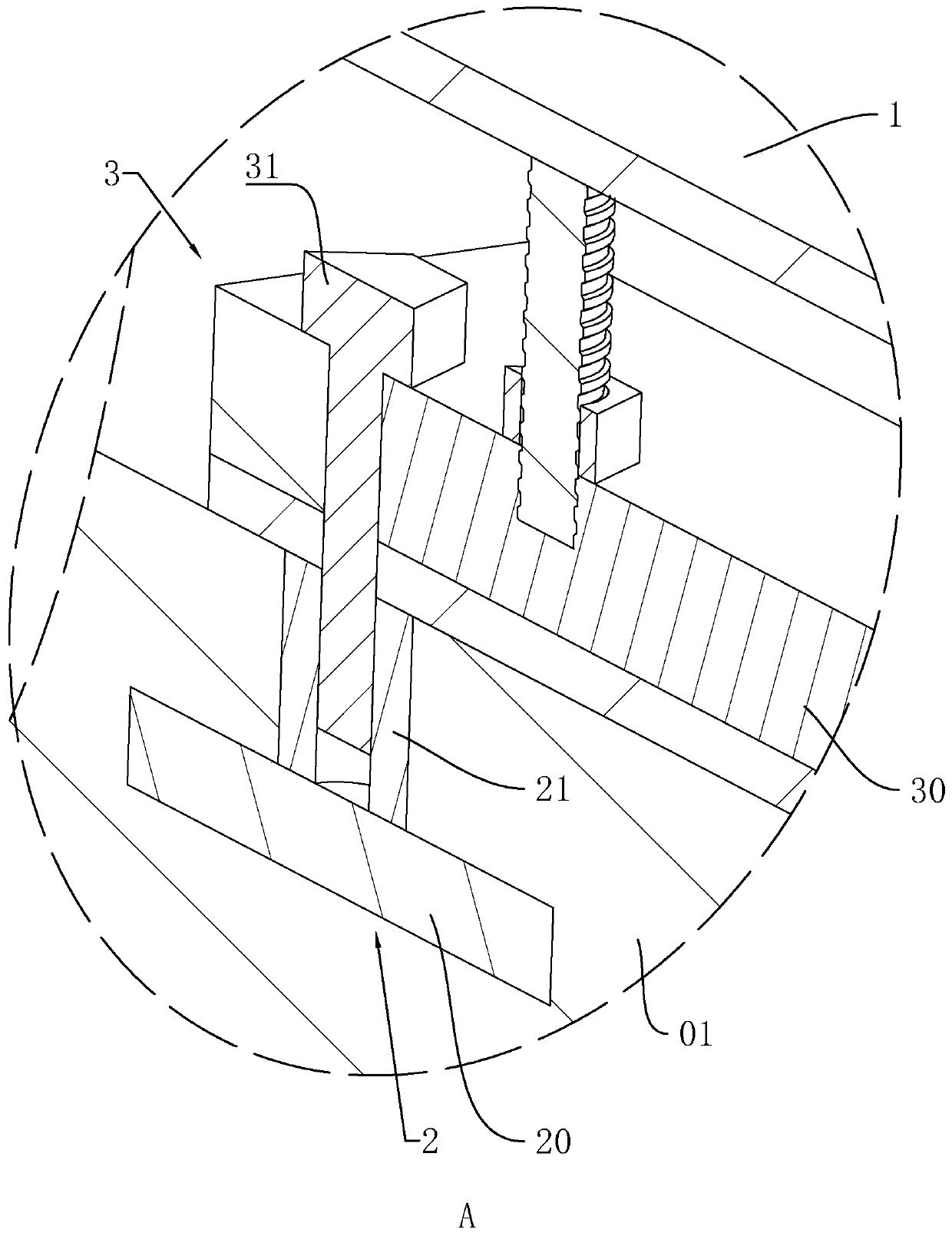

[0046] refer to figure 1 and figure 2 , a cantilever bearing frame, which includes a square pipe 1, a built-in part 2 arranged in the floor 01, a fixing part 3 inserted into the cavity of the square pipe 1 and connected with the built-in part 2, arranged in the floor 01 The limiting part 4 at the edge and used to fix the square pipe 1 and the hanging part 5 arranged on the wall 02 , the hanging part 5 is used to connect the end of the square pipe 1 away from the fixing part 3 .

[0047] refer to figure 1 and figure 2 , on the wall 02 and under the square tube 1, a reinforcing rib plate 6 is pre-embedded, and the top wall of the reinforcing rib plate 6 is in contact with the bottom wall of the square tube 1; the installation stability of the square tube 1 on the floor 01 is increased; When installing the load-bearing frame, insert the fixing part 3 into the cavity of the square tube 1, connect the embedded part 2 with the square tube 1, lift the square tube 1 with the susp...

Embodiment 2

[0058] A method for installing a cantilever bearing frame, specifically as follows:

[0059] (1) Pre-embed the pre-embedded plate, connecting sleeve, limit plate, connecting plate and limit column in the floor, and pre-embed the reinforcing rib plate and connecting screw in the wall;

[0060] (2) Put the square pipe on the floor, one part of the square pipe is installed on the floor, and the other part extends out of the floor, and the rib plate is pressed against the bottom wall of the square pipe to increase the installation stability of the square pipe on the floor; according to The length of the square tube, drill holes on the fixed block and the clamping block, insert the clamping block of the fixed block into the groove, use the positioning bolt to perforate the clamping block and fix it in the groove, and multiple fixed blocks are spliced end to end to form a fixed plate and inserted into the square tube , perforate the head of the fixing plate and the bottom wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com