Automatic tilting overturning type barrel washing device

A bucket washing device and a reversing technology, applied in the field of garment printing and dyeing, can solve the problems of high labor intensity, affecting the health of operators, inconvenient operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

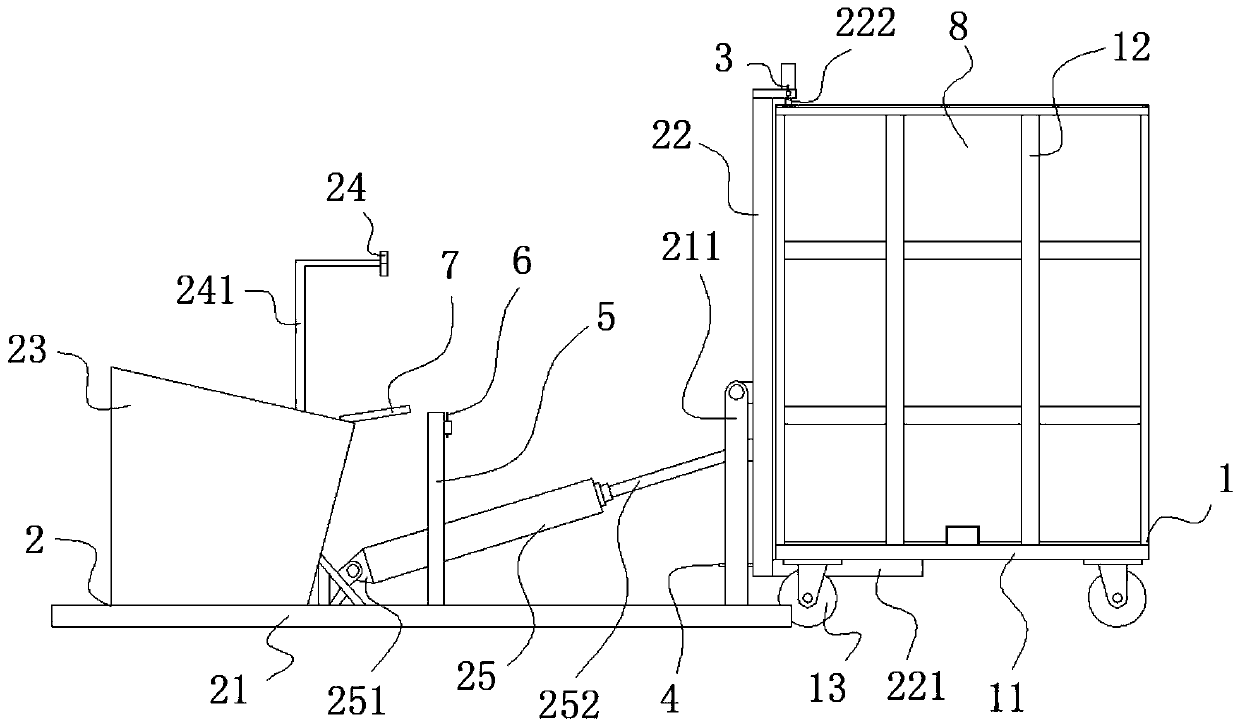

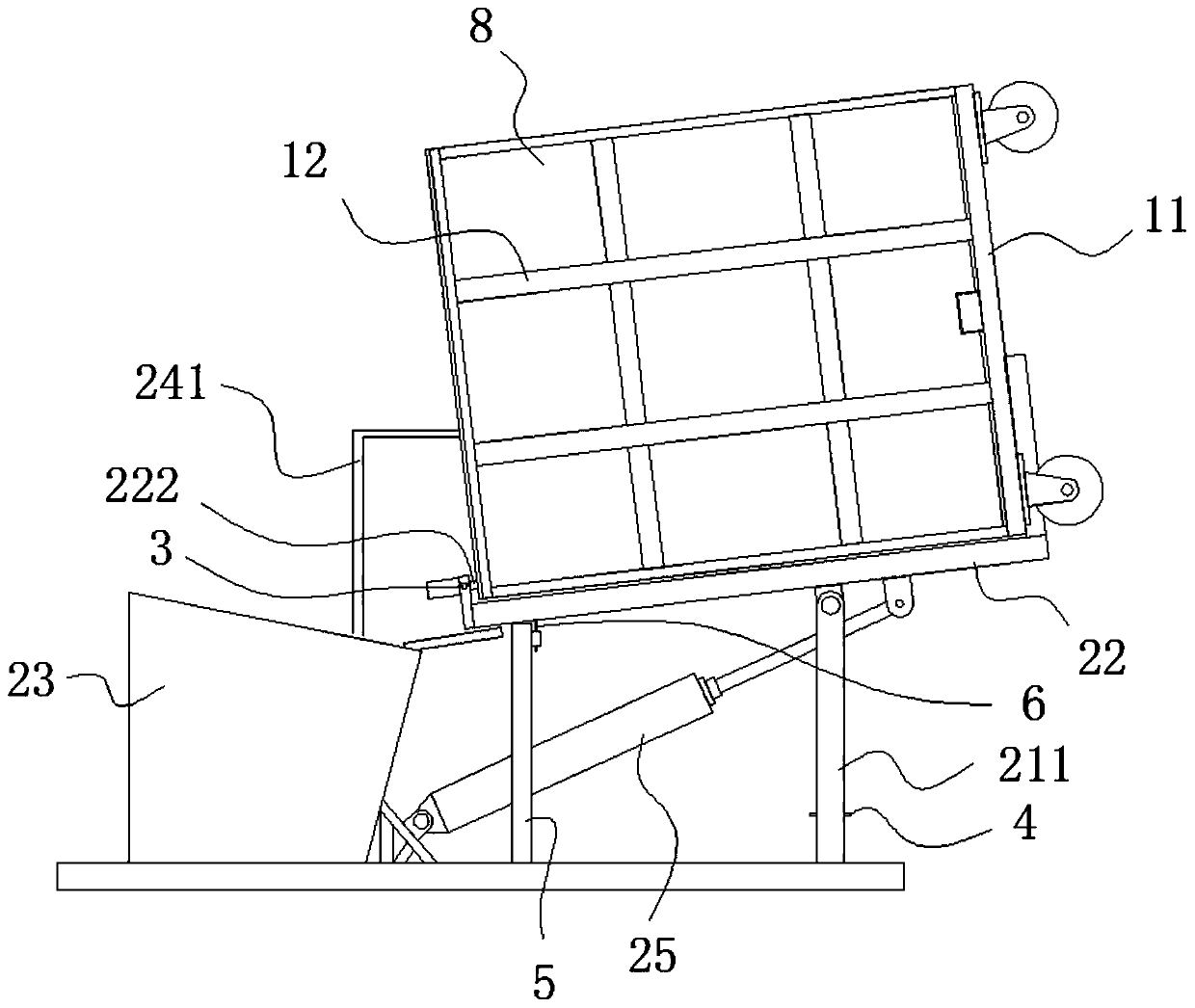

[0025] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach Figure 4 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

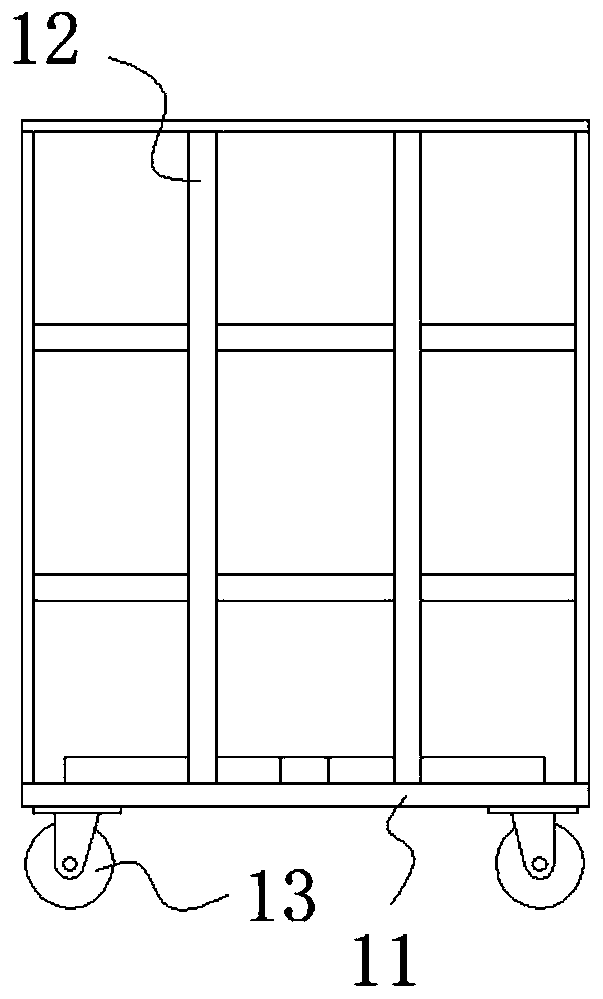

[0026] figure 1 It is a structure diagram in the initial state of an automatic dumping and flipping bucket washing device of the present invention; figure 2 It is a structural diagram of a preferred embodiment of the present invention in a dumped state. Such as figure 1 and figure 2 As shown, the automatic dumping and flipping bucket washing device provided in this embodiment includes: a moving bracket 1 and a flipping assembly 2. The bucket 8 is placed in the moving bracket 1 and fixed, and the operator moves the moving bracket 1 to the flipping assembly. At 2 places, the overturning c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com